Tunnel lining joint waterproof sealing gasket easy to compress

A waterproof gasket and easy-to-compress technology, which is applied in tunnel lining, tunnel, shaft lining, etc., and can solve the problems of high assembly force of extrusion gasket, reduced assembly force of segment lining, and damage to the end of prefabricated segment joints, etc. , to achieve the effects of stable compression deformation direction, optimized assembly force, and optimized waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

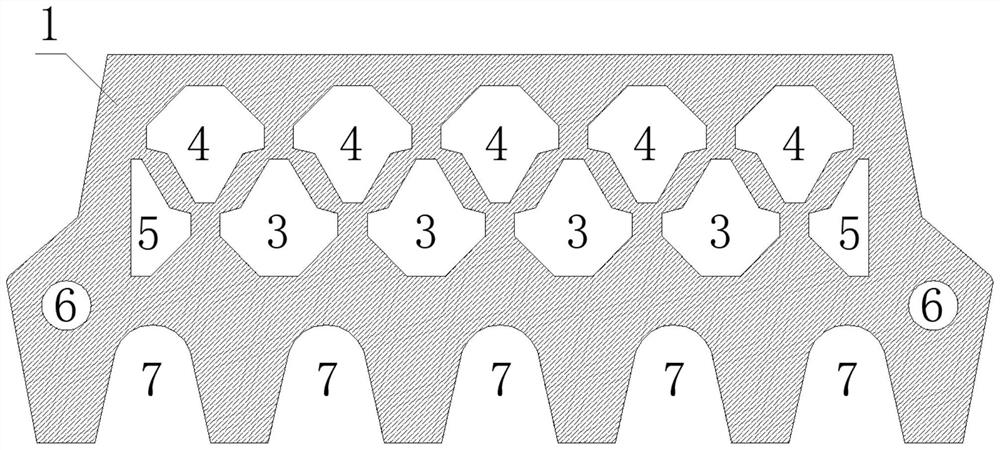

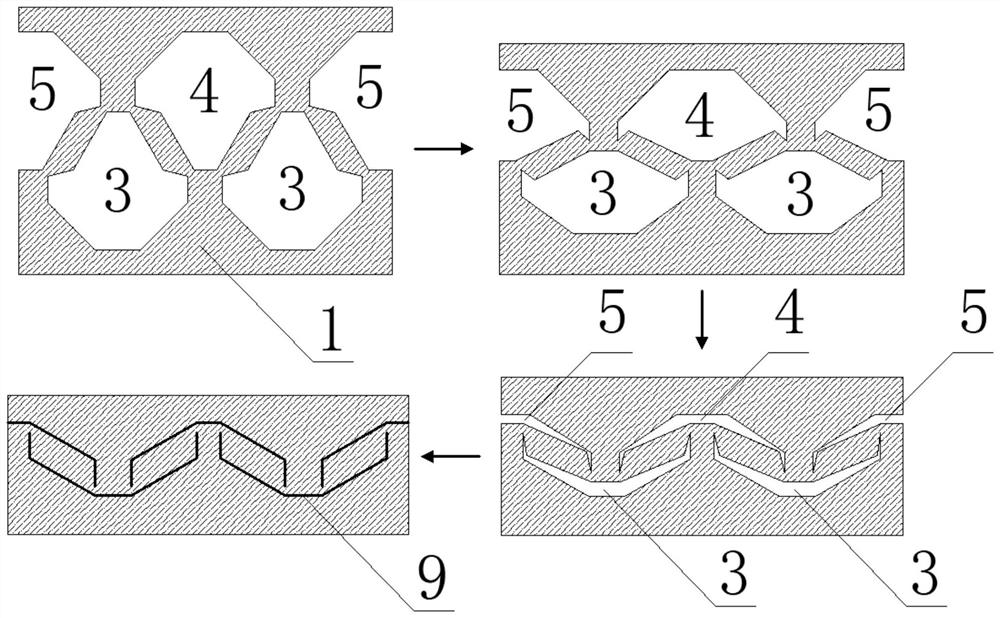

[0030] like figure 1 As shown, an example of the easily compressible waterproof sealing gasket for tunnel lining joints according to the present invention includes a gasket body 1 arranged in the waterproof groove 2; The installation end in the waterproof groove 2 and the extrusion end that can be extruded with the gasket body 1 of another shield segment; The opening shapes of the holes are like convex through holes 3, inverted convex through holes 4, half convex through holes 5, circular through holes 6 and inverted U-shaped through holes 7; the gasket body 1 from the bottom Up to the top, an inverted U-shaped through hole 7 , a circular through hole 6 , a semi-convex through hole 5 , a convex-like through hole 3 and an inverted convex-like through hole 4 are arranged in sequence.

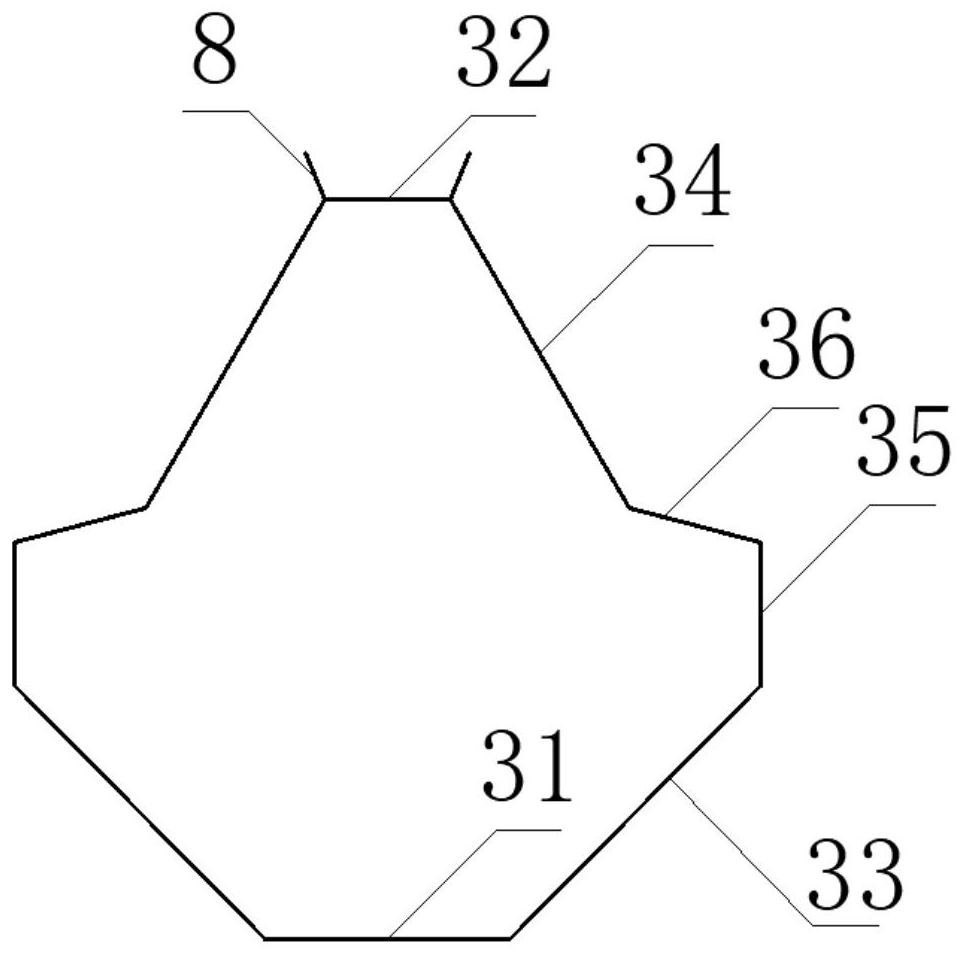

[0031] like figure 2 As shown, the specific size of the convex through hole 3 is designed to be the length L of the bottom edge 31 of the convex through hole. 1 Equal to the length L of the to...

Embodiment 2

[0041] Another example of the easily compressible waterproof gasket for tunnel lining joints according to the present invention, the gasket body 1 is sequentially provided with inverted U-shaped through holes 7, circular through holes 6, and semi-convex through holes from the bottom to the top. Hole 5, quasi-convex through hole 3 and inverted quasi-convex through hole 4, and the assembly force can be effectively controlled by reasonably setting the shape, size and position of the through hole to avoid damage to the segment. Extensibility, the tight fit between the waterproof gasket and the waterproof groove 2 and the gasket body 1 after being compressed and closed further ensures the waterproof effect

[0042] The other structures of this embodiment are the same as those of the first embodiment.

Embodiment 3

[0044] Another example of the easily compressible waterproof sealing gasket for tunnel lining joints according to the present invention, the quasi-convex through holes 3, semi-convex through holes 5 and inverted quasi-convex through holes 4 are a group of easily deformable through holes 3 The design of the hole makes the upper and lower two gasket bodies 1 tightly fit after being compressed in the contact area. The overall rigidity of the waterproof gasket in this area is large, and the contact surface is evenly stressed, which is more stable and reliable in long-term use. higher.

[0045] Other structures of this embodiment are the same as those of Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com