Atmosphere-controllable heat treatment equipment

A technology of heat treatment equipment and atmosphere, applied in the field of variable temperature experimental equipment, can solve problems such as sample damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

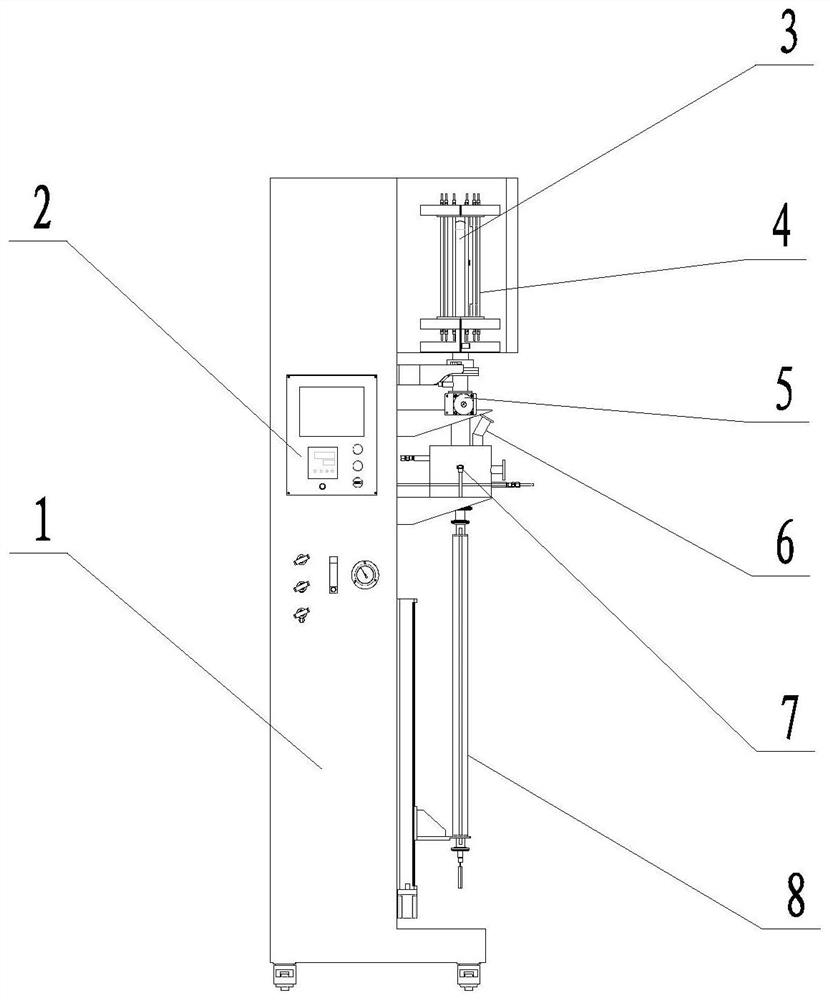

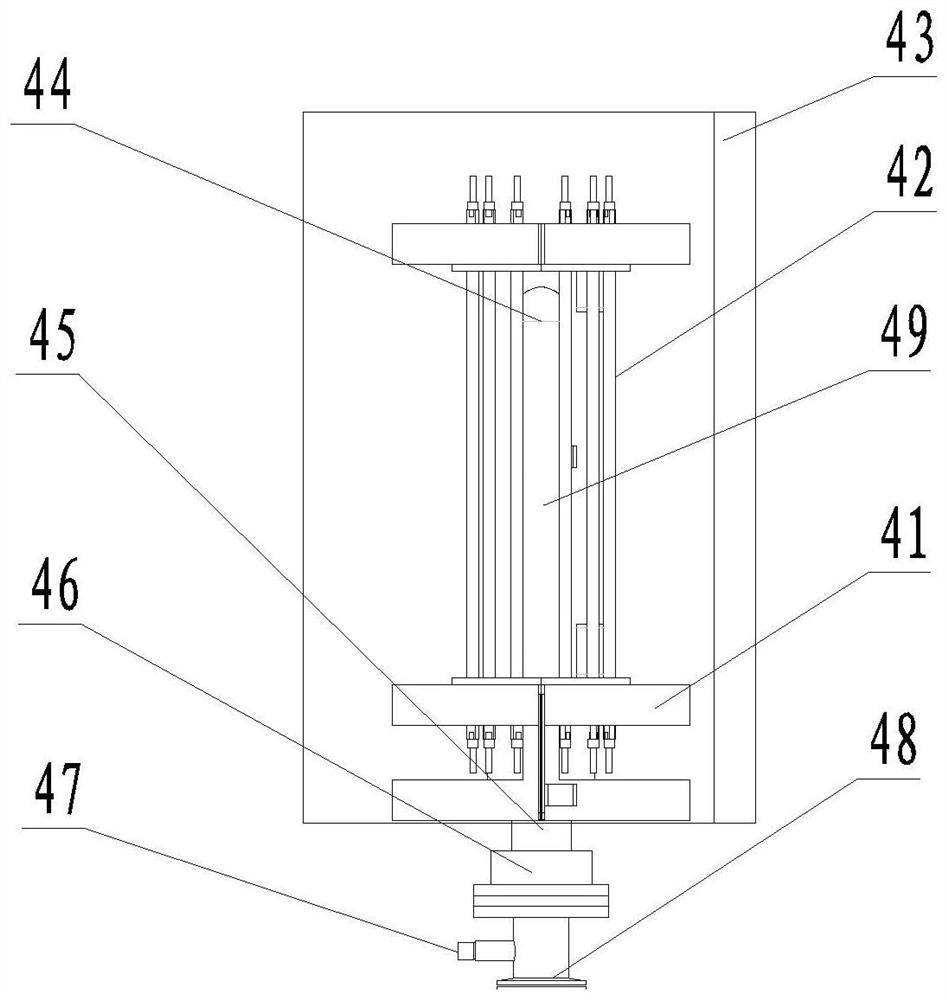

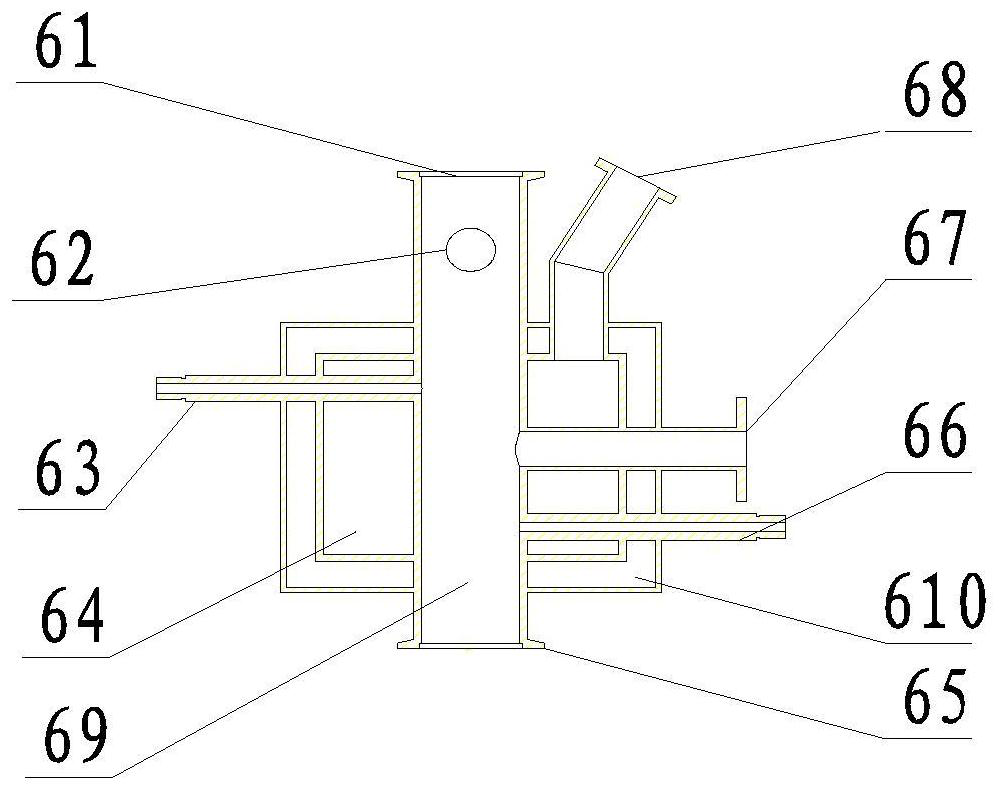

[0030] This embodiment discloses a heat treatment testing machine with a controllable atmosphere. The testing machine includes a main body 1, a control mechanism 2 and a testing mechanism 3; wherein the testing mechanism includes a heating system 4, a blocking structure 5, a cooling system 6, a lifting system The system 8 and the sample stage 7; the heating system 4 surrounds the furnace structure from the outside, and the furnace structure and the cooling system 6 have an inner cavity channel, and the two are connected by a blocking structure 5, and the blocking structure 5 controls the communication and blocking of the two, The lifting system 8 is docked with the other end of the cooling system 6 , and the sample stage 7 is located at the end of the lifting system 8 . The lifting system 8 can drive the sample stage 7 to move back and forth between the cooling system cavity 69 and the heating system cavity 49 . When the sample stage 7 moves up and down, it can ensure that the ...

Embodiment 2

[0039] This embodiment discloses a heat treatment testing machine with a controllable atmosphere. The testing machine includes a main body 1, a control mechanism 2 and a testing mechanism 3; wherein the testing mechanism includes a heating system 4, a blocking structure 5, a cooling system 6, a lifting system The system 8 and the sample stage 7; the heating system 4 contains a furnace body structure, and the furnace body structure and the cooling system 6 have an inner cavity channel, and the two are connected by a barrier structure 5, and the barrier structure 5 controls the connection and blocking of the two. The lifting system 8 is docked with the other end of the cooling system 6 , the sample stage 7 is located at the end of the lifting system 8 , and the lifting system 8 can drive the sample stage 7 to move back and forth between the cooling system cavity 69 and the heating system cavity 49 . When the sample stage 7 moves up and down, it can ensure that the placed sample i...

Embodiment 3

[0048] This embodiment discloses an environment simulation testing machine with a controllable atmosphere. The testing machine includes a main body 1, a control mechanism 2 and a testing mechanism 3; wherein the testing mechanism includes a heating system 4, a blocking structure 5, a cooling system 6, The lifting system 8 and the sample stage 7; the heating system 4 contains a furnace body structure, and the furnace body structure and the cooling system 6 have an inner cavity channel, and the two are connected by a barrier structure 5, and the barrier structure 5 controls the connection and blocking of the two, lifting and lowering. The system 8 is docked with the other end of the cooling system 6 , the sample stage 7 is located at the end of the lifting system 8 , and the lifting system 8 can drive the sample stage 7 to move back and forth between the cooling system cavity 69 and the heating system cavity 49 . When the sample stage 7 moves up and down, it can ensure that the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com