Wafer sorting equipment

A sorting and equipment technology, applied in sorting, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of limiting production capacity, slow sorting speed, etc., to meet sorting accuracy and efficiency requirements, sorting Choose the effect of fast speed and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: the concrete structure of the present invention is as follows:

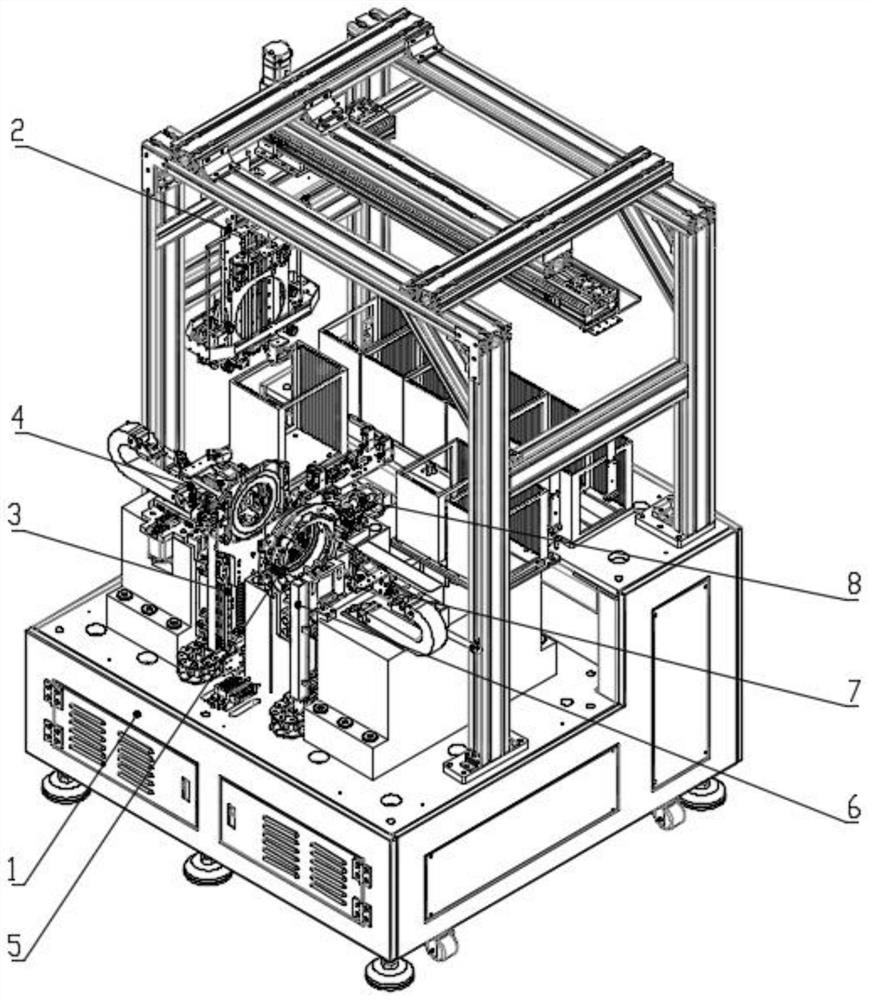

[0070] Please refer to the attached Figure 1-8 , A wafer sorting equipment of the present invention includes a rack 1, and the rack 1 is provided with a feeding station and a sorting station, and the sorting equipment further includes:

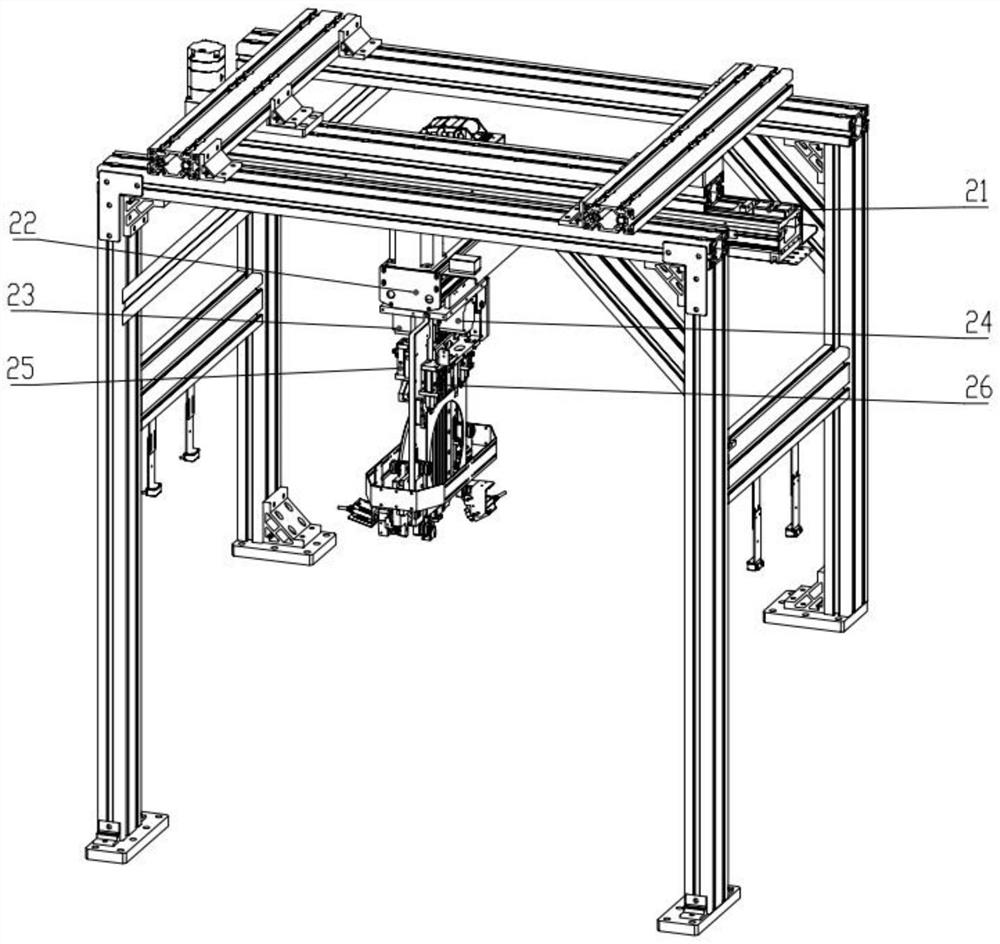

[0071] The feeding mechanism 2 installed at the feeding station, the feeding mechanism 2 is suspended on a shelf, and is provided with a first XYZ three-axis linkage mechanism and a crystal mounted on the first XYZ three-axis linkage mechanism. Disc clamping mechanism 25 and Bin disc clamping mechanism 26;

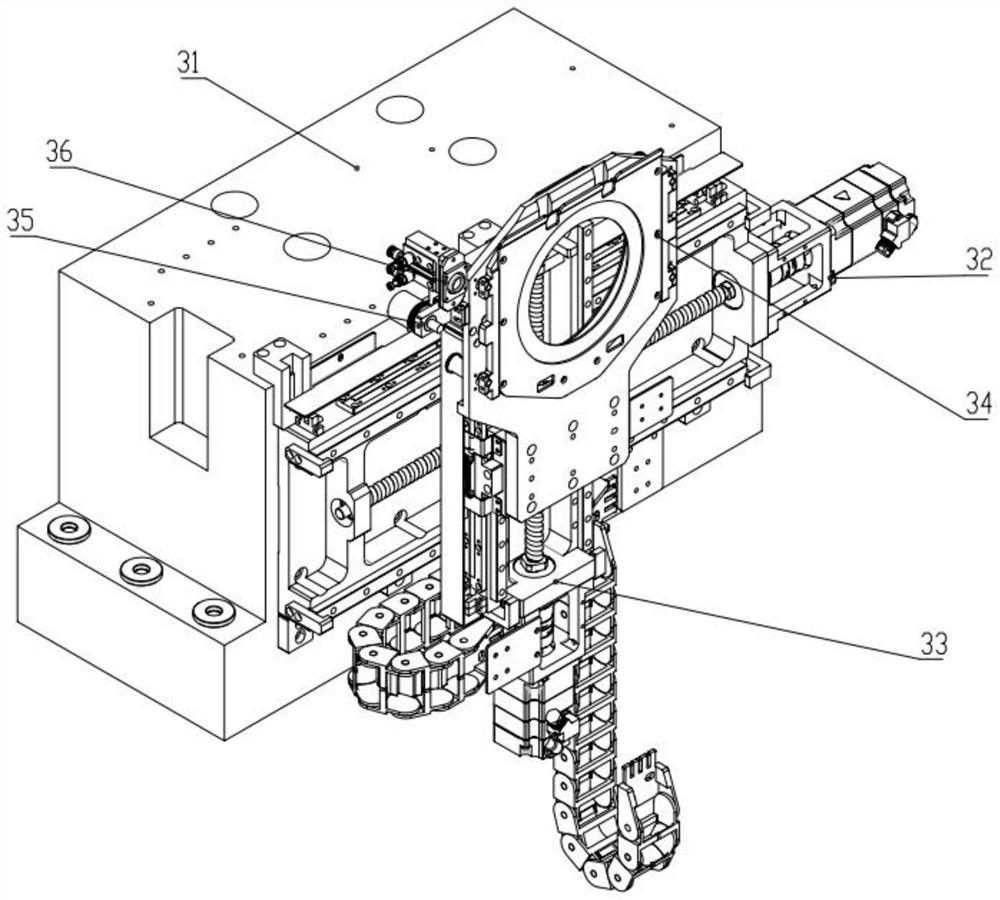

[0072] The wafer stage mechanism 3 has a first base (31) mounted on the rack 1, a first YZ-axis motion module mounted on the first base 31, and the first YZ-axis motion module A wafer assembly is driven and connected, and a wafer fixing mechanism 34, a light source 35 and a suction nozzle wiping device 36 are respectively installed on the wafer assembl...

Embodiment 2

[0120] The following is the working principle of the wafer sorting equipment of the present invention:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com