Plate shape control process for producing pipeline steel based on single-stand steckel mill

A technology for steel coil mills and production pipelines, which is applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve problems such as unconsidered flatness control methods, and achieve the effect of reducing flatness problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

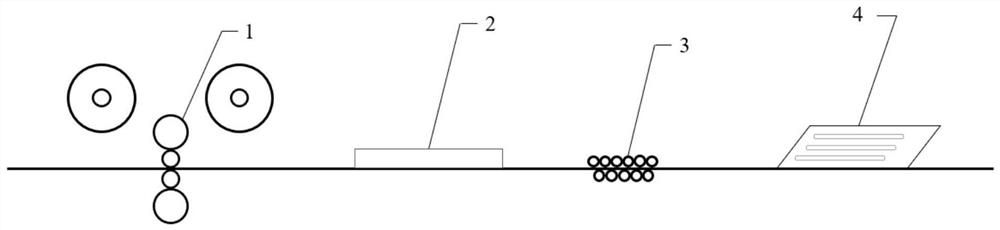

Image

Examples

Embodiment 1

[0028] Use 150mm billet to produce L450M pipeline steel with a daughter plate size of 10.3×2580×12000mm, and the number of feet is 5 times. The yield strength of this grade of steel is required to be ≥465MPa. The specific implementation process is as follows:

[0029] (1) Slab heating

[0030] The slab tapping temperature is 1160°C, and the furnace time is 7min / cm.

[0031] (2) high-pressure water descaling;

[0032] The water pressure of the descaling box is ≥23MPa, and the surface temperature of the slab after descaling is between 1030℃.

[0033] (3) Rolling

[0034] Before rolling L450M pipeline steel, 5 pieces of Q355B were produced, the thickness specification was 14.2mm, the width specification was 2900mm, and the finishing temperature was 848℃, 834℃, 845℃, 853℃ and 837℃ respectively.

[0035] The intermediate billet of L450M pipeline steel is set to 35mm, the second-stage rolling is 11 passes, the reduction rate of the penultimate pass is 19.5%, and the reduction ra...

Embodiment 2

[0044] Use 150mm billet to produce L485M pipeline steel with daughter plate specification of 13×2486×12000mm, the multiples of feet are 4 times of feet, and the yield strength of this grade of steel is required to be ≥515MPa. The specific implementation process is as follows:

[0045] (1) Slab heating

[0046] The slab tapping temperature is 1180°C, and the furnace time is 8min / cm.

[0047] (2) high-pressure water descaling;

[0048] The water pressure of the descaling box is ≥23MPa, and the surface temperature of the slab after descaling is between 1040℃.

[0049] (3) Rolling

[0050] Before rolling L485M pipeline steel, 5 pieces of Q345R were produced, the thickness specification was 20.15mm, the width specification was 3100mm, and the finishing temperature was 887℃, 880℃, 877℃, 874℃ and 888℃ respectively.

[0051] The intermediate billet of L485M pipeline steel is set to 45mm, the second-stage rolling is 13 passes, the reduction rate of the penultimate pass is 15%, and ...

Embodiment 3

[0060] Use 150mm billet to produce L450M pipeline steel with a daughter plate size of 14.2×2580×12000mm, and the number of feet is 4 times. The yield strength of this grade of steel is required to be ≥450MPa. The specific implementation process is as follows:

[0061] (1) Slab heating

[0062] The slab tapping temperature is 1200°C, and the furnace time is 9min / cm.

[0063] (2) high-pressure water descaling;

[0064] The water pressure of the descaling box is ≥23MPa, and the surface temperature of the slab after descaling is between 1060℃.

[0065] (3) Rolling

[0066] Before rolling L450M pipeline steel, 5 pieces of Q355B were produced, the thickness specification was 14.2mm, the width specification was 2900mm, and the finishing temperature was 835℃, 837℃, 840℃, 857℃ and 847℃ respectively.

[0067] The intermediate billet of L450M pipeline steel is set to 35mm, the second-stage rolling is 11 passes, the reduction rate of the penultimate pass is 18%, and the reduction rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com