Steel pipe mark jet printing equipment and steel pipe branch-by-branch mark jet printing method thereof

A technology for equipment brackets and steel pipes, which is applied to the field of steel pipe marking jet printing equipment and its steel pipe mark printing field, can solve the problems of mutual collision, wear of jet printing marks, low recognizable rate of marks, etc. The effect of low overall cost and improved recognizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

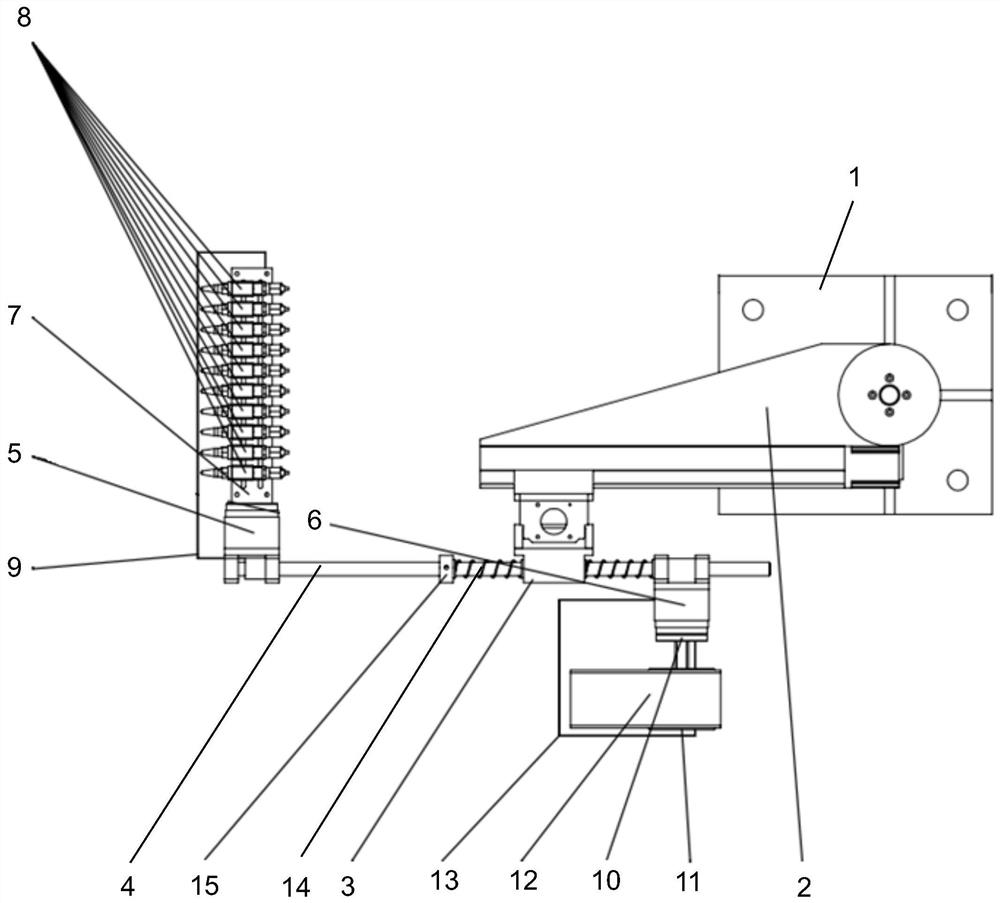

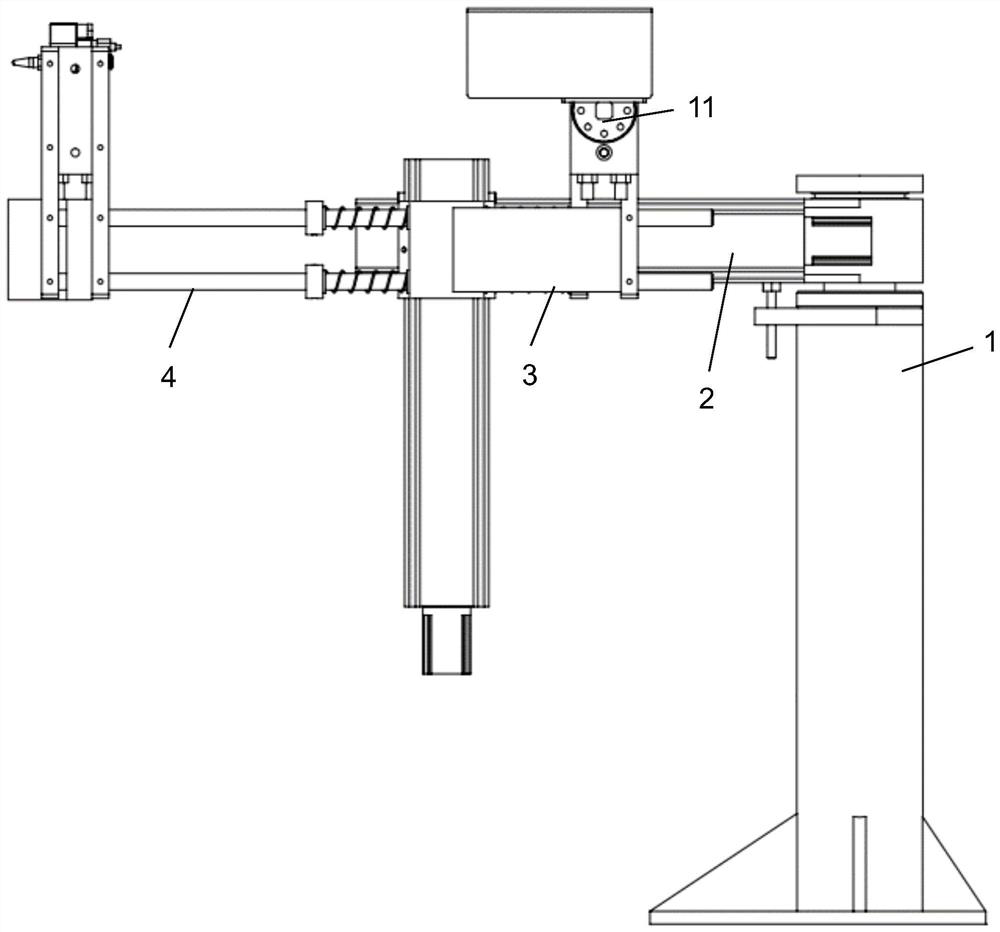

[0033] In order to better understand the above technical solutions of the present invention, the technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

[0034] please combine figure 1 , figure 2 As shown in the figure, a steel pipe identification spray printing equipment provided by the present invention includes an equipment support 1, a swing rod 2 installed on the top of the equipment support 1, an optical axis seat 3 is installed on the swing rod 2, and an optical axis seat 3 is installed on the optical axis seat 3. The connecting rod 4 has a first rotating cylinder 5 mounted on the front end of the connecting rod 4 and a second rotating cylinder 6 mounted on the rear end of the connecting rod 4 .

[0035] A spray gun seat fixing member 7 is installed on the first rotating cylinder 5 , and a spray gun seat 8 and a spray gun cleaning box 9 are installed on the spray gun seat fixing member 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com