Endoscope machining clamp and enoscope machining method

A refracting mirror, machining technology, applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problem that the quality of the mirror surface is difficult to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

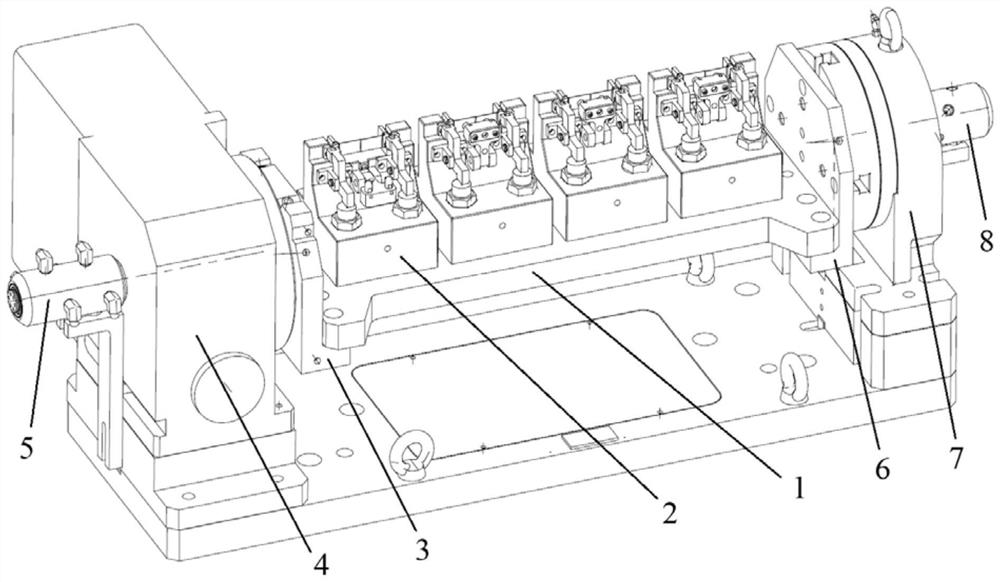

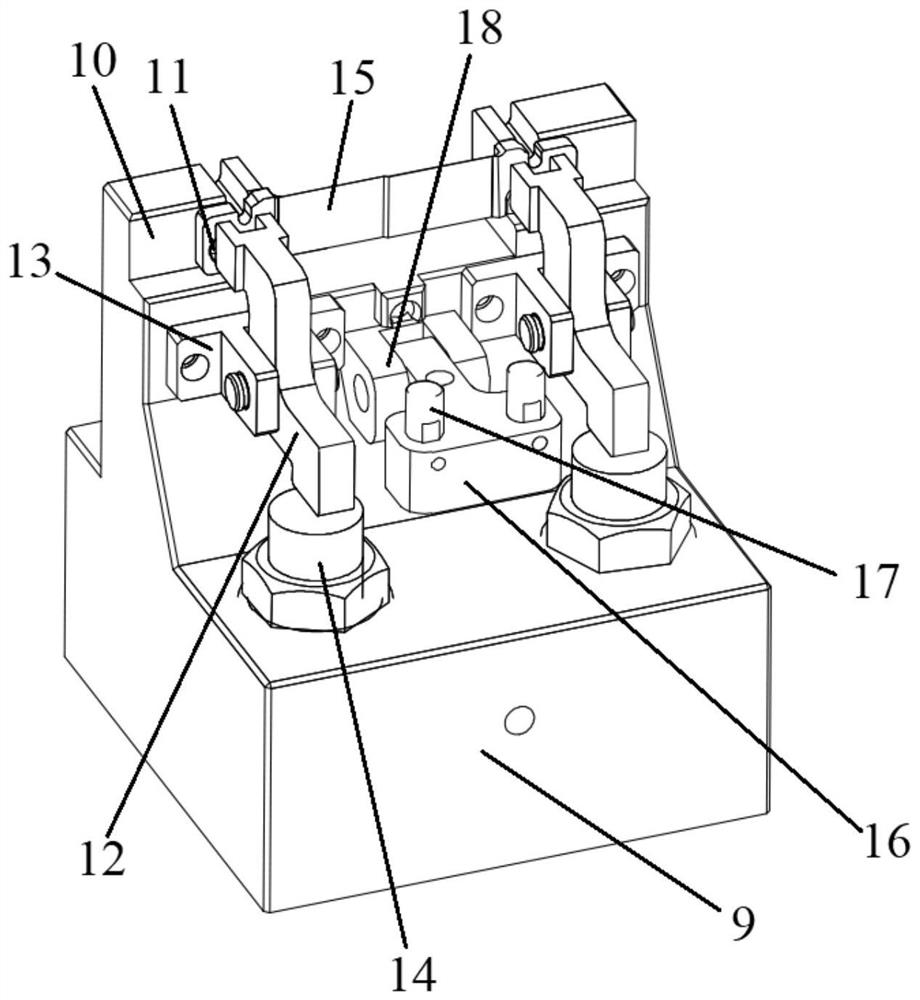

[0031] This embodiment provides a refracting mirror machining fixture, such as figure 1 As shown, the machining fixture comprises a bridge plate 1 and four identical fixture units 2 located on the bridge plate 1 . In other examples, other numbers of clamp units 2 (eg two, three or more) may also be used. Using a plurality of fixture units 2 is beneficial to improve the efficiency of machining. Inside the bridge plate 1 is a hydraulic oil circuit and an air circuit, which are respectively communicated with the hydraulic components and air pressure sensors of each fixture unit 2 . The bridge plate 1 is connected with the horizontal CNC turntable 4 through the left L-shaped connecting plate 3 . At the same time, the rear end of the CNC turntable 4 is equipped with a hydraulic oil rotary joint 5, the fixed end of which is connected to the oil outlet of the hydraulic station, and the rotating end is connected to the oil circuit of the left L-shaped connecting plate 3, and the lef...

Embodiment 2

[0036] The present embodiment also provides a method for machining a refracting mirror, which mainly includes the following steps:

[0037] (1) Put the four workpieces (refractors to be processed) into the positioning seats of their respective fixture units, stick to the positioning surfaces, and clamp the positioning pins.

[0038] (2) Start the NC program, the clamping cylinder lifts the lever pressing plate, each lever pressing plate clamps the workpiece, and starts the processing of the shape of the refractor blade.

[0039] (3) The CNC turntable is rotated to the low beam mirror surface processing angle, and the low beam mirror surface is rough and finely milled.

[0040] (4) Rotate the CNC turntable to the processing angle of the high beam mirror surface, lift the floating support device (folded state) to support the low beam mirror surface processed in step (3), and then rough and finely mill the high beam mirror surface.

[0041] (5) The CNC turntable rotates to the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com