Novel pressurizing mechanism for hydraulic tire vulcanizing machine and hydraulic tire vulcanizing machine

A tire vulcanization and pressurization mechanism technology, which is applied in tires, applications, household appliances, etc., can solve the high cost of configuration and maintenance costs of the pressurization mechanism, difficulty in controlling the synchronization of the pressurization mechanism, and the reduction of piston rod tension and other issues, to achieve the effect of reducing configuration costs and later use and maintenance costs, reducing configuration costs, and shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of the present invention, the present invention will be described more comprehensively and in detail below with reference to the accompanying drawings and preferred embodiments of the specification, but the protection scope of the present invention is not limited to the following specific embodiments. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0039] In order to realize the purpose of the present invention, the technical scheme provided by the present invention is:

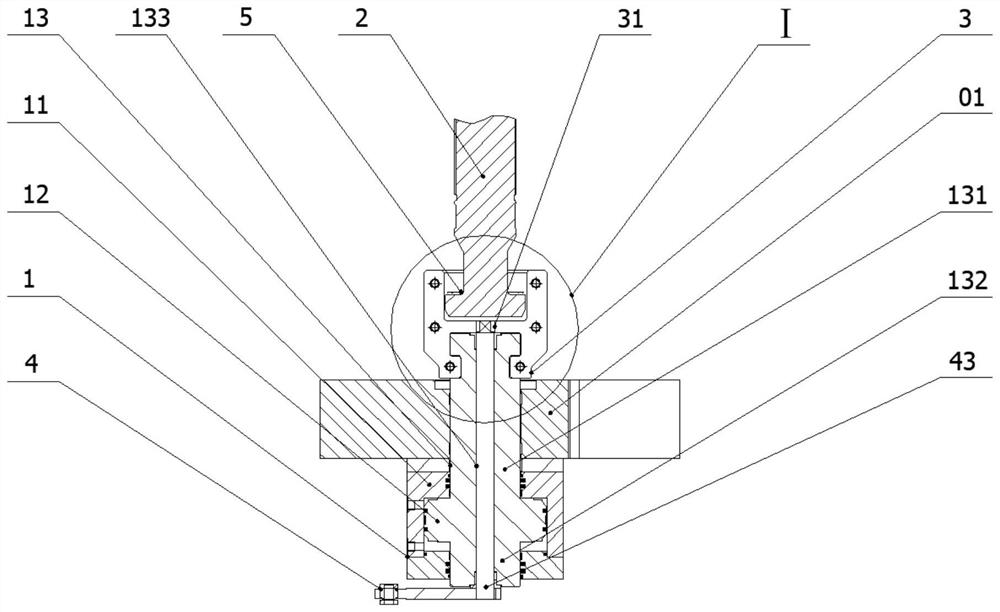

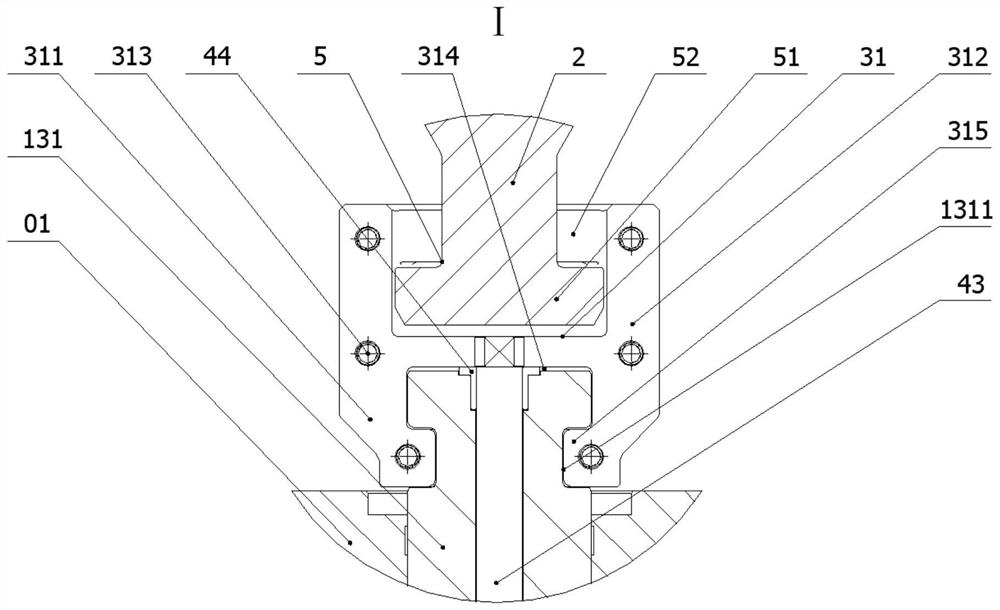

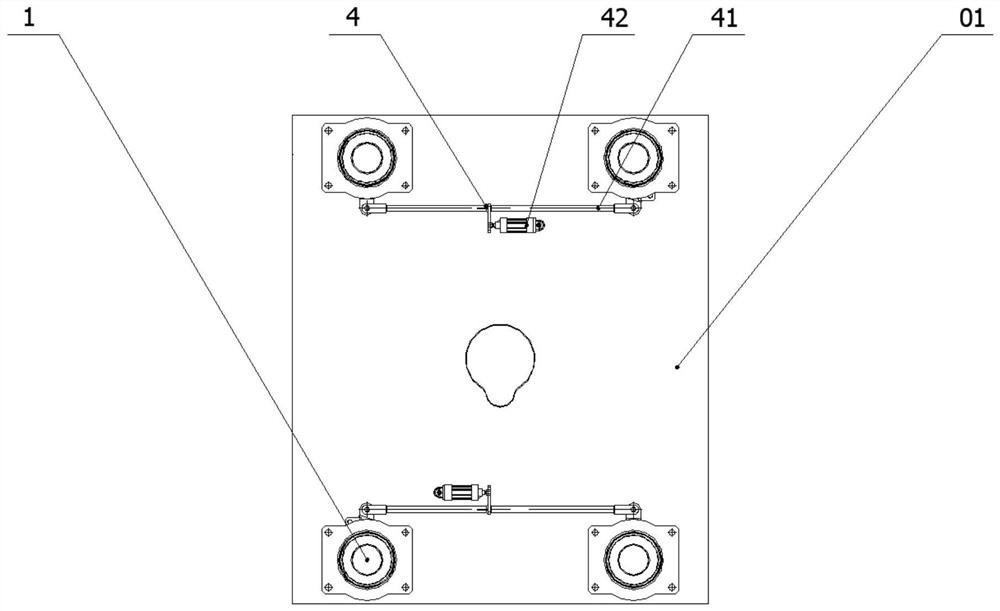

[0040] In some embodiments of the invention, such as figure 1 , 4, 6, 7, a new type of pressurizing mechanism for hydraulic tire vulcanizers is disclosed, including: pressurizing oil cylinder 1, upper pull rod 2, pull down rod assembly 3 and loosening / locking device 4; pressurized oil cylinder 1. Set on the lower surface of the base 01 in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com