Integral high-speed train inner windshield

A high-speed train, integrated technology, applied in the direction of railway car body, railway car body parts, climate sustainability, etc., can solve the problem of uneven transition of tooth-shaped concave-convex shape of bellows structure, and poor sound insulation and noise reduction performance Ideal, poor heat insulation and sound insulation performance, etc., to achieve the effect of good sound insulation performance, good curve passing ability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

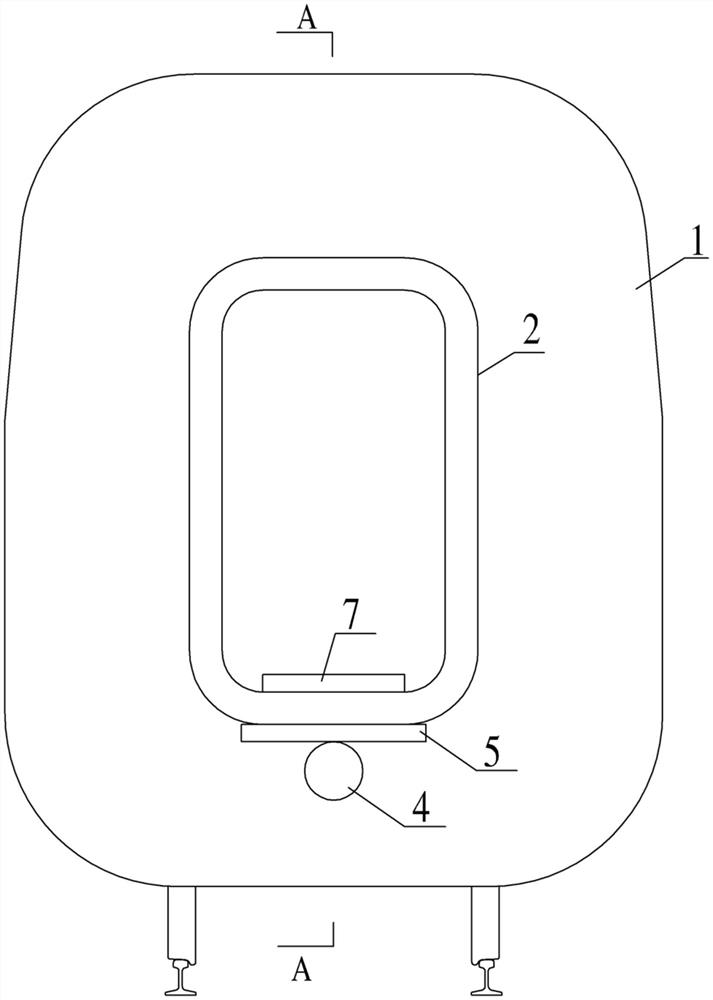

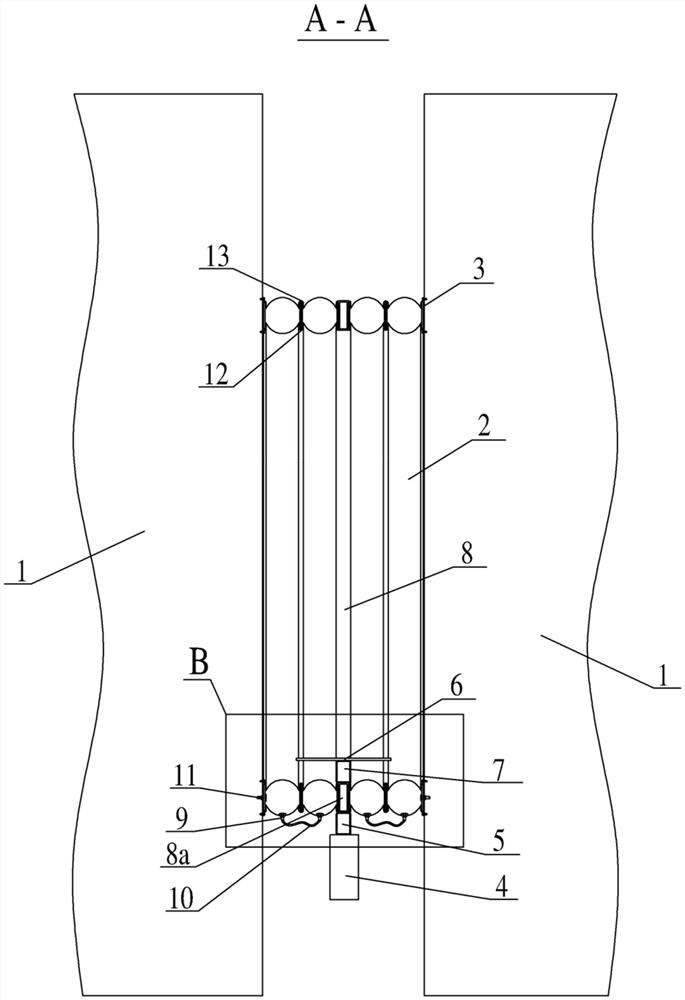

[0034] Figure 1-Figure 3 It is shown that the first specific embodiment of the present invention is: an integral high-speed train inner windshield, characterized in that:

[0035] A plurality of integral ring-shaped rubber airbags 2 are combined into a rubber airbag group, the end face of the vehicle 1 is fixed with a vehicle end mounting frame 3 by bolts, and a rubber airbag group is fitted and fixed in the card groove of the vehicle end mounting frame 3 of the front vehicle , the other rubber airbag group is fitted and fixed in the card slot of the vehicle end mounting frame 3 of the rear vehicle;

[0036] A transverse lower support beam 5 is fixed on the upper support surface of the coupler 4 on the end face of the front vehicle; the channel pedal 6 of the front vehicle is fixedly connected to the transverse upper support beam 7; the upper support beam 7 and the lower support beam 5 are respectively connected with The top surface and bottom surface of the bottom frame 8a ...

Embodiment 2

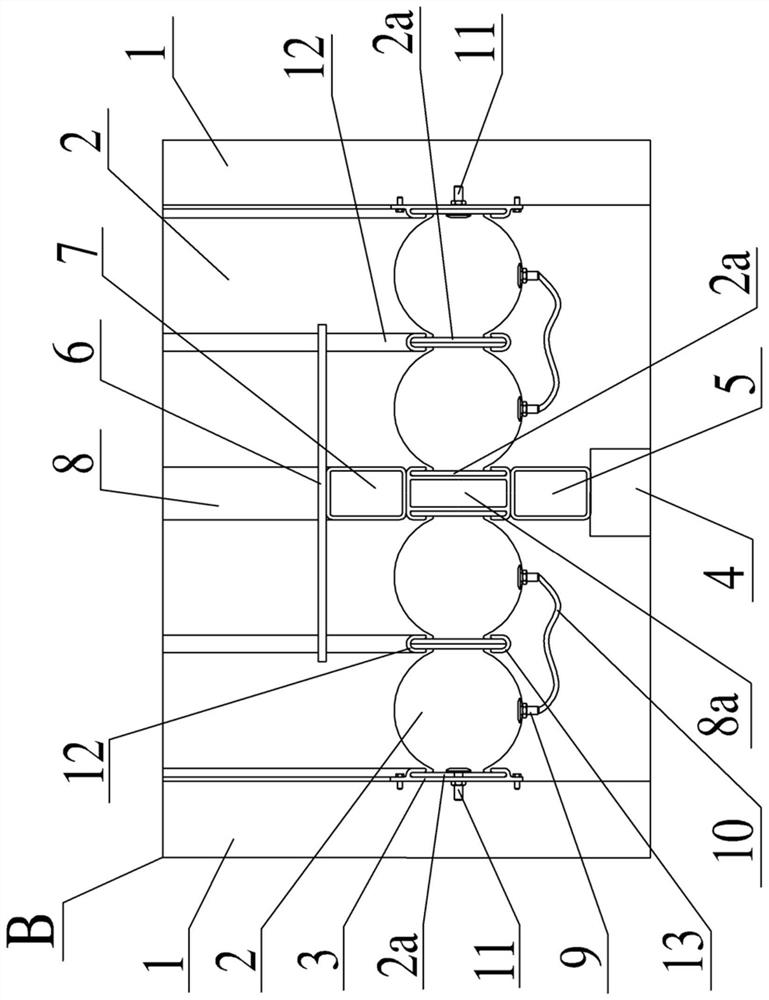

[0044] Figure 4-Figure 6 It is shown that the second specific embodiment of the present invention is: an integral high-speed train inner windshield, characterized in that:

[0045] A plurality of ring-shaped rubber air bags 2 are combined into a rubber air bag group, and the end face of the vehicle 1 is fixed with a vehicle end mounting frame 3 by bolts; the front side of the rubber air bag group is fitted and fixed in the card groove of the vehicle end mounting frame 3 of the front vehicle , the rear side of the rubber airbag group is fitted and fixed in the groove of the vehicle end mounting frame 3 of the rear vehicle.

[0046] The rubber airbag 2 is provided with a communication valve 9, and the communication valve 9 of the adjacent rubber airbags 2 in the rubber airbag group is connected by a communication hose 10; any rubber airbag 2 in the rubber airbag group is connected with the controllable air valve 11. The inflation air source is connected, and the controllable a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com