Pipe and bar material distributing mechanism and method

A material-distributing mechanism and pipe-rod technology, applied in conveyors, vibrating conveyors, conveyor objects, etc., can solve problems such as low efficiency, time-consuming and labor-intensive, personnel injuries, etc., to improve personal safety factor, reduce manual intervention, use low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

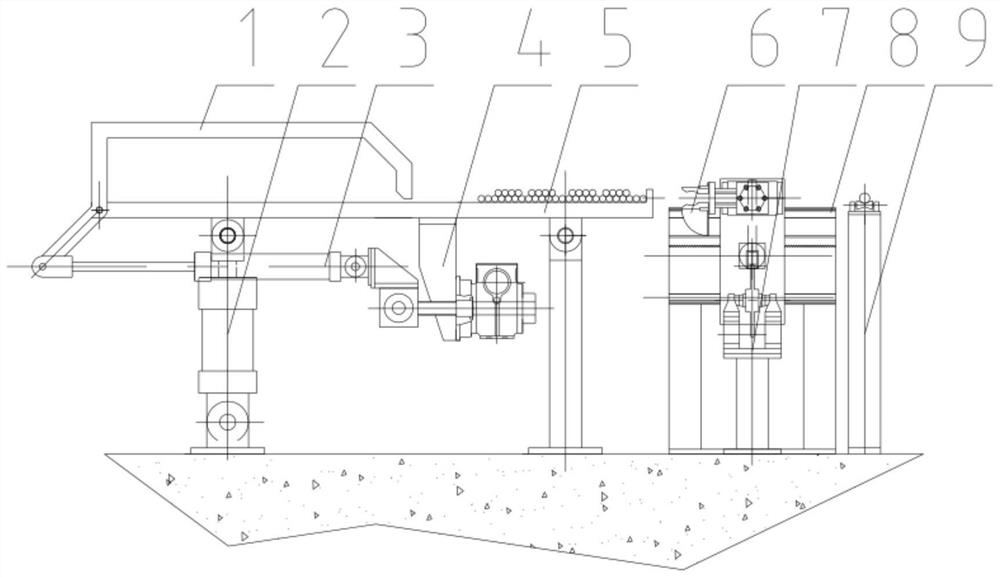

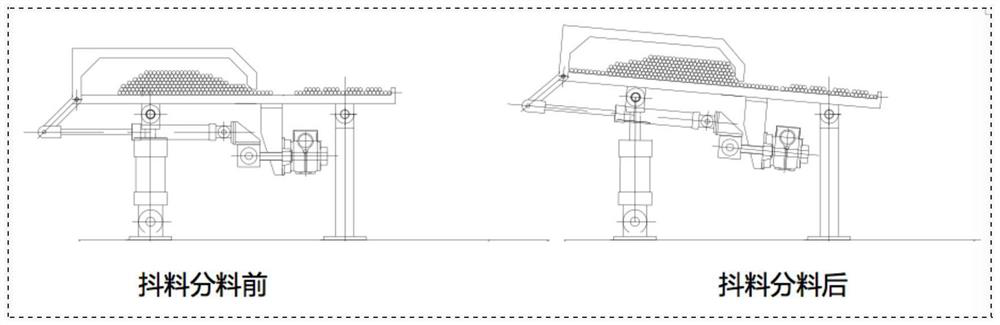

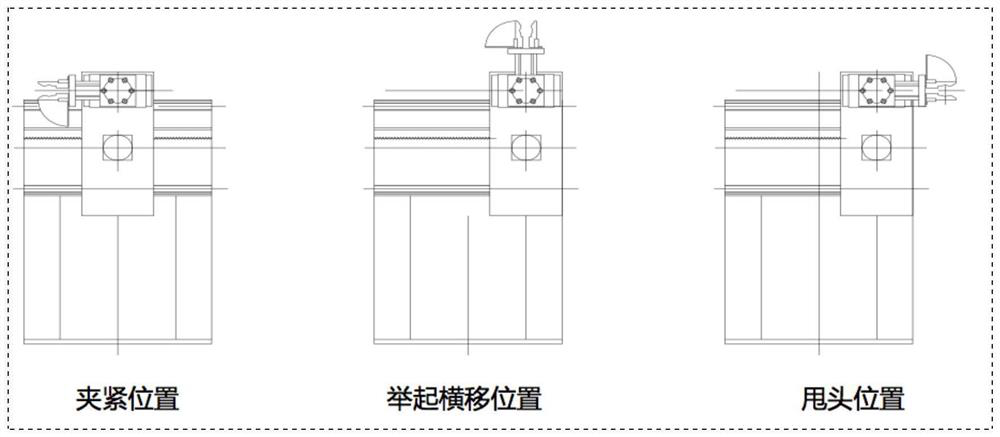

[0025] like Figure 1-3 and Figure 5 As shown in the figure, a pipe and rod material distributing mechanism includes a turning frame 1, a shaking oil cylinder 2, a turning frame opening and closing oil cylinder 3, a fine adjustment device for the opening and closing degree of the turning frame 4, a material shaking and bulk material frame 5, and a clamping and turning head device 6 , the feeder 7, the clamping device base 8 and the discharge roller table 9, the material shaking and bulk material rack 5 includes a flat plate 5-1 and a support frame 5-2, the flat plate 5-1 is arranged horizontally, and the lower part of the flat plate 5-1 is Connect the shaking oil cylinder 2, the turning frame opening and closing degree fine-tuning device 4 and the support frame 5-2 in turn from left to right. The lower left end of the frame 1 is connected to the left end of the flat plate 5-1 and the flip frame 1 is located on the upper side of the flat plate 5-1, the clamping and flipping h...

Embodiment 2

[0028] On the basis of Embodiment 1, the flip frame 1 includes an upper plate, a left plate and a right plate, the left end of the upper plate is connected to the left plate at the bottom, the right end of the upper plate is connected to the right plate at the bottom, and the lower end of the left plate is rotatably connected to the The left end; the rotating connection is convenient to open or close the flip frame 1; preferably, the lower end of the left plate is connected to the left end of the flat plate 5-1 through a pin, the connection method is simple and easy to operate; the upper plate, the left plate and the right plate are combined or integrated Structure; choose according to actual needs, with strong selectivity.

[0029] Preferably, the lower right end of the flip frame 1 is not connected to the flat plate 5-1.

[0030] The lower right end of the turning frame 1 is the lower end of the right plate. When the shaking cylinder 2 shakes, it is ensured that the pipe and...

Embodiment 3

[0039] On the basis of Embodiment 2, when the shaking oil cylinder 2 shakes, it shakes up and down. The up-and-down shaking makes full use of the action of gravity, so that the tube and bar slide out of the crimping area of the turning frame along the gap under the action of gravity, from disorder to one layer at most two layers, the principle and operation are simple.

[0040] Preferably, the support frame 5-2 is an up and down telescopic support frame; it is convenient to control the lifting and lowering of the right part of the flat plate 5-1.

[0041] Preferably, the turning frame opening and closing degree fine adjustment device 4 includes an oil cylinder and a lifter, the oil cylinder is connected to the lifter, the power output end of the oil cylinder is connected to the power input end of the turning frame opening and closing oil cylinder 3, and the power output end of the lifter is connected to the bottom of the flat plate 5-1. ; The oil cylinder opens or closes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com