Oil separation tank for restaurant sewage

A technology for catering sewage and grease traps, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, grease/oily substance/floating matter removal device, etc. The oil effect is poor, the filter element is easy to clog and other problems, and the oil removal effect is good, the filtering effect is increased, and the filter element is easy to replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

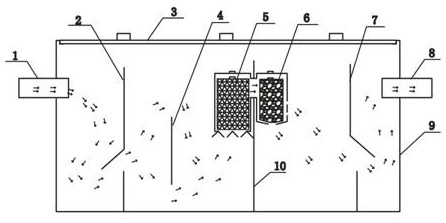

[0015] Please refer to figure 1 , a catering sewage grease trap provided by this embodiment includes a box body 9, and a water inlet pipe 1 and a water outlet pipe 8 are respectively fixed on the left and right sides of the box body 9 near the upper end surface. At the same time, the box body 9 The top surface opening is hollow inside, the top surface of the box body 9 is movably fixed with the box body cover plate 3, and the lower end surface of the box body 9 is fixed with three partition plates arranged horizontally with each other, from left to right are the front partition plate 2, the middle partition The plate 10 and the rear partition 7, the three partitions divide the box 9 into four cavities, from left to right are the sedimentation part, the slag removal part, the oil removal part I and the oil removal part II. Each partition has an opening, the opening of the front partition and the opening of the rear partition are horizontal, the opening of the middle partition i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com