Rapid carding device and method for production of environment-friendly antibacterial fabric

A kind of fabric and environmental protection technology, applied in the field of fast carding device for the production of environmentally friendly and antibacterial fabrics, can solve the problems of troublesome and accidental injury of staff by carding device, and achieve the effects of avoiding injury, improving carding work efficiency and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

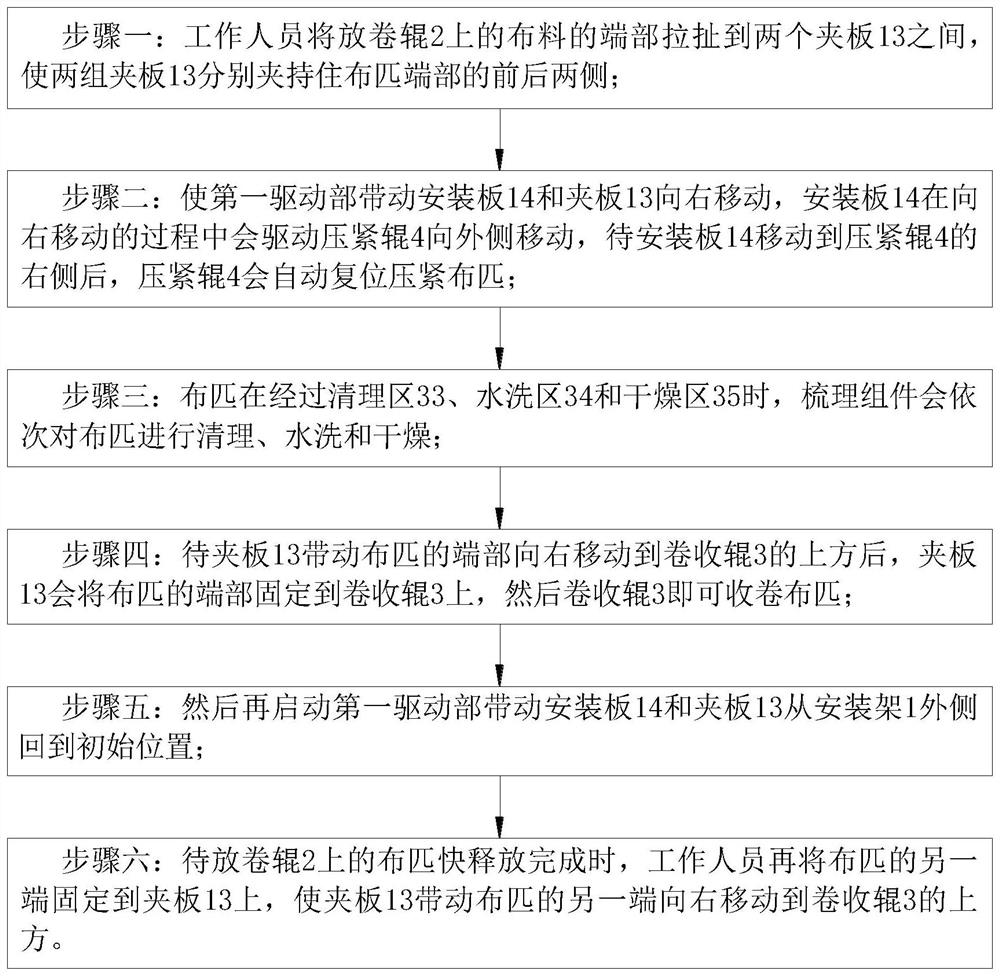

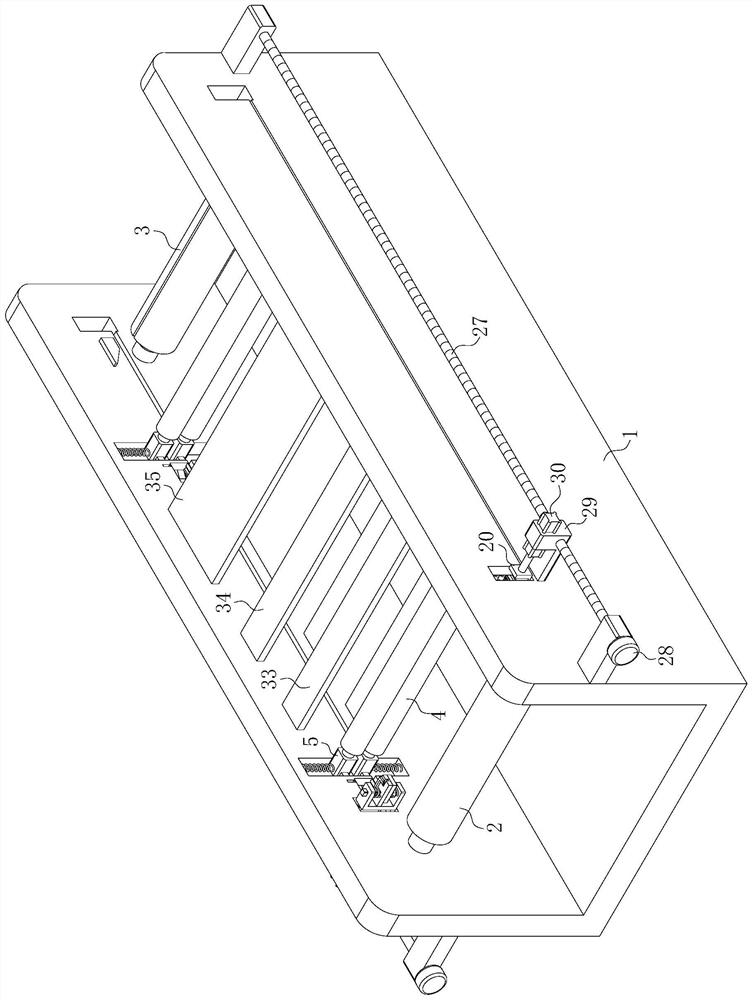

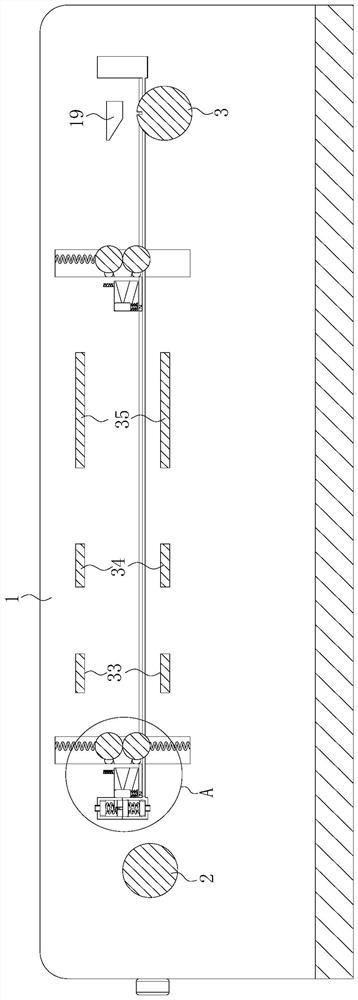

[0035] See Figure 1-9 , the present invention provides a technical solution: an environmentally friendly bacteriostatic fabric production for the rapid grooming apparatus, comprising a mounting rack 1, the mounting frame 1 is U-shaped, the mounting frame 1 on the inner wall of the rotation is connected to the unwinding roller 2 and the reeling roller 3, the reeling roller 3 is located in the lower right of the unwinding roller 2, the mounting frame 1 is provided with a carding component, the carding assembly is located between the unwinding roller 2 and the reeling roller 3, the left and right sides of the carding assembly are provided with a pressure roller group, The left side of the pressure roller set and the release roller 2 is provided with a clamping assembly, the clamping assembly for the end of the cloth placed on the roll 2 is clamped and the end of the cloth from the two pressure roller groups passed, and then the end of the cloth is transported to the roll 3 for fixati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com