Air curtain ring assembly of combustor

A burner and air curtain technology, applied in the direction of burners, gas fuel burners, combustion types, etc., to achieve the effect of improving the thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

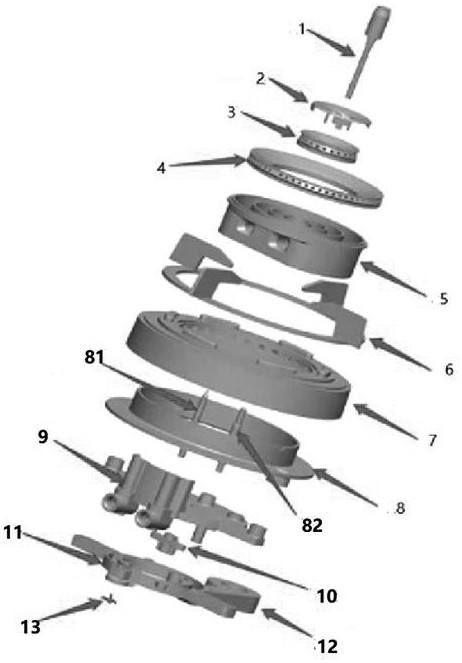

[0035] see attached figure 1 , is a schematic diagram of the overall structure of the burner with the air curtain ring assembly. In this embodiment, the burner is composed of a dry burning probe 1, a heat insulation sheet 2, an inner ring fire cover 3, an outer ring fire cover 4, a furnace head 5, a furnace frame 6, an air curtain ring 7, and an air curtain groove 8 , The base 9, the fixing bolt 10, the premixing channel 11, the blower 12, the magnetic field fan 13 constitute the whole of a stove combustion system.

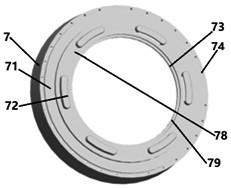

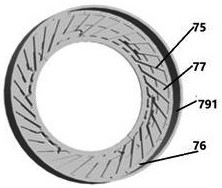

[0036] see attached Figure 2a , 2b and image 3 , the second embodiment is about the overall structure of the air curtain ring assembly in the burner. It is composed of air curtain ring 7, furnace frame fixing position 71, air supplementary hole 72, burner suspension groove 73, air curtain hole 74, secondary premixing groove 75, air oxygen supplementary ring cavity 76, heat sink 77, air The inner ring 78 of the curtain ring, the inner edge step 79 of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com