Glucose biosensor

A biosensor and glucose technology, applied in the field of medical diagnosis, can solve the problems that the performance cannot meet the needs of continuous glucose monitoring and the working life is only one week, and achieve the effect of improving sensitivity, simplifying design and fabrication, and simplifying design and fabrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Chemical Modification of Glucose Dehydrogenase

[0035] Incubate 1-10 mg / ml of glucose dehydrogenase (optimal value: 5) in PBS buffer solution containing 1-6 mol / L urea (optimal value: 3) at 4 degrees for 8-24 hours (optimum Value: 12), fully expand the glucose dehydrogenase. Then 1-10 mg / ml (best value: 5) of ruthenium or osmium complexes with free amino groups are fully mixed with 1-10 mg / ml glucose dehydrogenase (best value: 5), Then add 0.2-10 mmol / L carbodiimide (optimum value: 1) and 0.1-1 mmol / L N-hydroxysuccinimide (optimum value: 0.5) in sequence, after mixing thoroughly, React at 4 degrees for 8-24 hours (best value: 12). Then, the modified glucose dehydrogenase was separated and purified by ultrafiltration bag dialysis (cutting molecular weight: 1000-30000, optimal value: 10000). The purified glucose dehydrogenase can directly exchange electrons effectively with the electrode;

[0036] To further improve the rapid electron exchange between gluc...

Embodiment 2

[0037] Example 2: Preparation of Glucose Sensing Membrane

[0038] 1. Preparation

[0039] Mix 2-20 mg / ml (best value: 5) modified glucose dehydrogenase in PBS buffer solution with 0.1-5% (best value: 1) glutaraldehyde solution for 30-180 minutes Finally (optimum value: 60), the chemically cross-linked glucose dehydrogenase is coated on the surface of the electrode to form a glucose sensing film by the drop coating method or the dipping and pulling method.

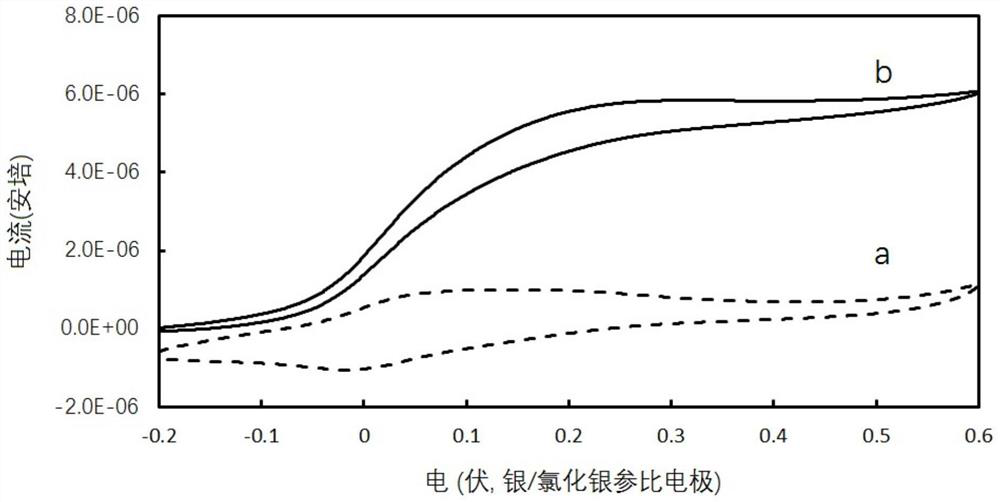

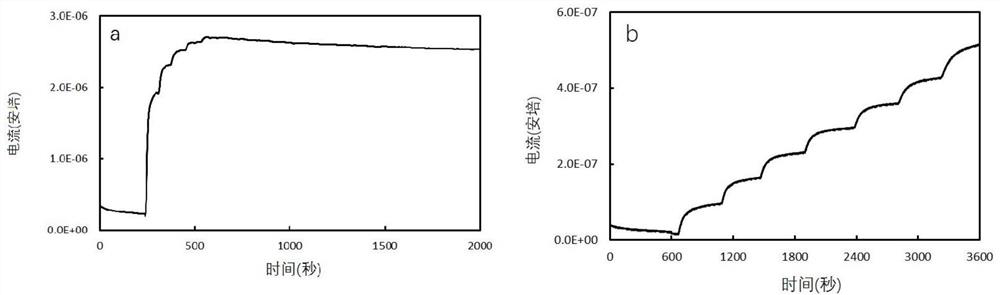

[0040] 2. Characterization of electrochemical activity

[0041] The glucose sensing membrane containing modified glucose dehydrogenase was characterized by cyclic voltammetry, and the results are shown in figure 2 . figure 2 Curve a clearly shows that after the above treatment, the redox small molecule with superior electrochemical performance has been successfully bonded to glucose dehydrogenase. When 5 mmol / L glucose was added to the PBS buffer solution, the cyclic voltammogram of the glucose sensing membrane clear...

Embodiment 3

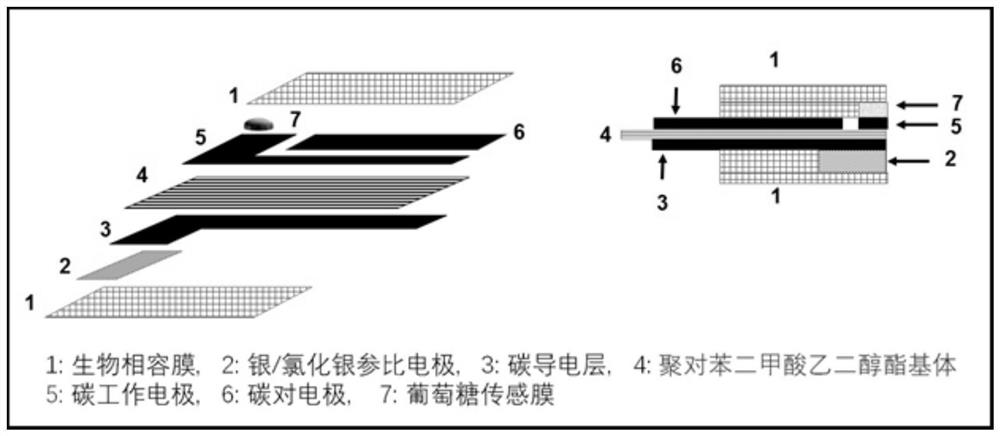

[0042] Example 3: Preparation of biocompatible membrane and glucose biosensor

[0043] 1. Preparation of biocompatible membrane

[0044] (1) Synthesis of polyhydroxyethyl methacrylate: 5-500 milliliters of hydroxyethyl methacrylate (best value: 100)+10-1000 milliliters of dehydrated alcohol (best value: 300) and 1- 100ml (best value: 30) of water, deoxygenated with argon for 10-60 minutes (best value: 30). Then add 10-1000 mg (best value: 200) of Na 2 S 2 o 8 , placed in an airtight container, and reacted at 50-75°C (best value: 70) for 10-40 hours (best value: 24). Then add 500-5000 milliliters of acetone (best value: 2500) to precipitate polyhydroxyethyl methacrylate, and centrifuge. Add ethanol to dissolve, then add 500-5000 ml (best value: 2500) acetone to precipitate, and centrifuge. Repeat several times, and finally dry the precipitate at 60-120°C (best value: 100) in vacuum for at least 8-24 hours (best value: 12).

[0045](2) Coating of polyhydroxyethyl methacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com