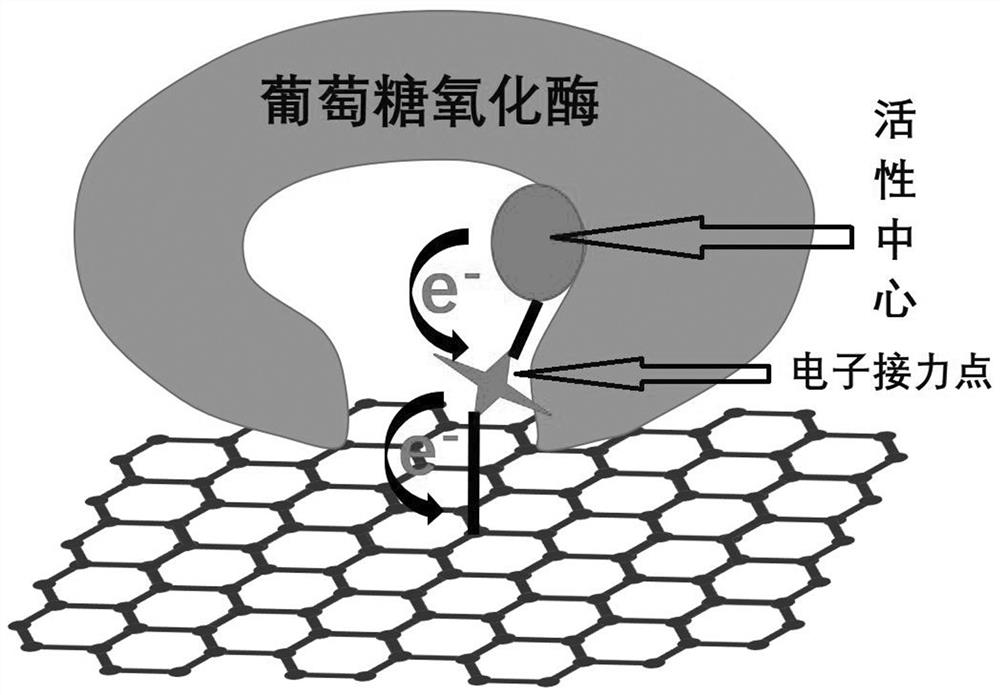

Glucose biosensing membrane, glucose oxidase and preparation method thereof

A glucose oxidase and sediment technology, applied in the field of glucose biosensing membranes, can solve problems affecting product consistency, high viscosity of glucose oxidase solution, etc., and achieve the effect of improving sensitivity and maintaining catalytic oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of glucose oxidase, comprises the steps:

[0042] A), the deprosylation of glucose oxidase:

[0043] A1), dissolving glucose oxidase in 3~7mol / L ammonium sulfate solution, culturing for 1~4 hours, and then performing centrifugation at a speed of 10000~15000 rpm for 10~30 minutes; preferably, ammonium sulfate The concentration is 4.5~6mol / L;

[0044] A2) Discard the upper layer of centrifuged liquid, dissolve the precipitate in 0.1~2mol / L sodium acetate solution, and slowly add the sodium acetate solution into 3~7mol / L ammonium sulfate solution, the pH of the solution is 1.4, and incubate for 1~4 hours , and then centrifuged again at a speed of 10,000 to 15,000 revolutions per minute for 10 to 30 minutes, repeating this step several times; preferably, the concentration of ammonium sulfate is 4.5 to 6 mol / L;

[0045] A3), discard the supernatant centrifugate, wash the precipitate with phosphate buffer solution of 12~36mmol / L (preferably, 18~27mmol...

Embodiment S1

[0064] (1), the deprosylation of glucose oxidase:

[0065] Dissolve 2 g of glucose oxidase in a 5.6 mol / L ammonium sulfate solution with a pH of 1.4 and incubate for 2 hours; then, pour the obtained ammonium sulfate solution into a centrifuge tube and centrifuge at a speed of 1300 rpm for 20 minutes; Discard the supernatant, and dissolve the precipitate in 1 mol / L sodium acetate; slowly add the sodium acetate solution to a 5.6 mol / L ammonium sulfate solution with a pH of 1.4, and after incubating for 2 hours, pour the obtained solution into a centrifuge tube Centrifuge at a speed of 13,000 rpm for 20 minutes; discard the supernatant, and dissolve the precipitate in 1 mol / L sodium acetate; slowly add the sodium acetate solution to a 5.6 mol / L ammonium sulfate solution with a pH of 1.4, Cultivate for 2 hours, then pour the resulting solution into a centrifuge tube, and centrifuge at a speed of 13,000 rpm for 20 minutes; discard the supernatant and wash with 20 mmol / L phosphate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com