Method for producing oxygen through six towers adsorption

An oxygen production method and adsorption tower technology, applied in the field of six-tower adsorption oxygen production, can solve the problems of low power generation efficiency, large power consumption, complicated operation and maintenance, etc., so as to improve oxygen production level and work efficiency, reduce oxygen production cost, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

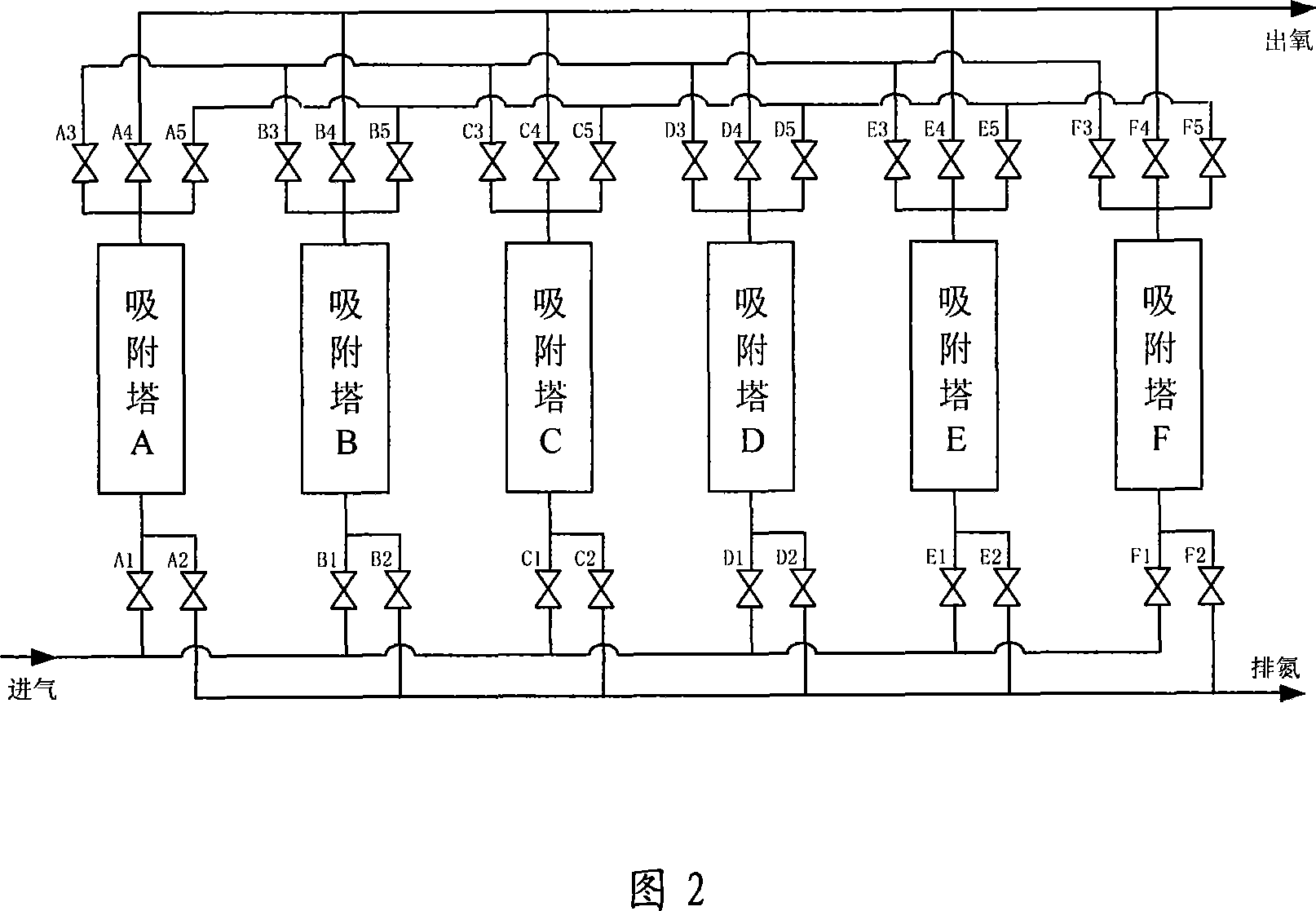

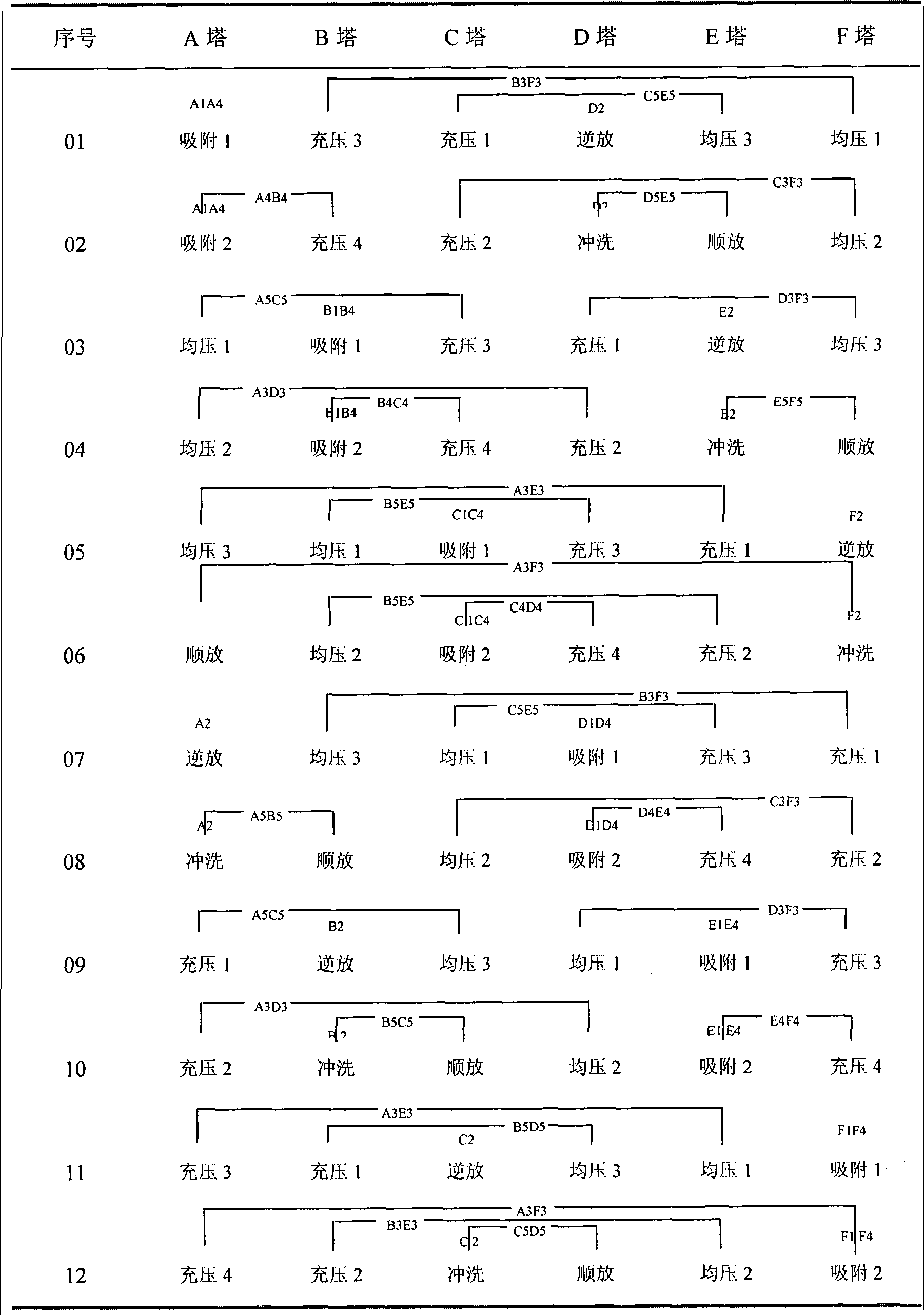

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

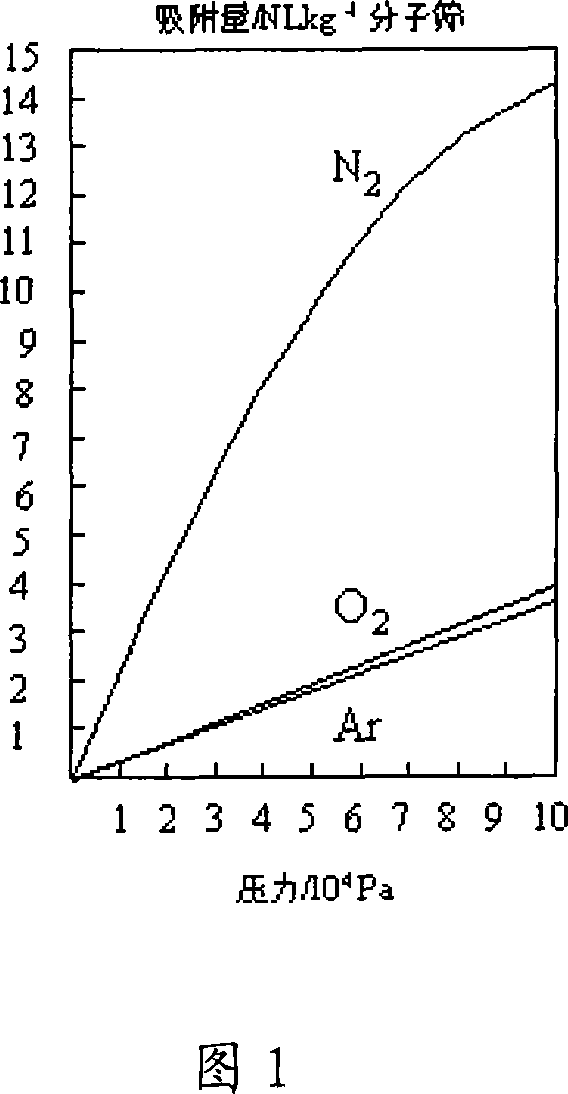

[0027] The invention utilizes the principle of molecular sieve pressure swing adsorption oxygen production to produce oxygen. The components in the air are shown in Table 1, wherein the main components are nitrogen and oxygen, nitrogen accounts for about 78%, oxygen accounts for about 21%, and other components account for about 1%.

[0028] ingredients

Volume ratio

ingredients

Volume ratio

Nitrogen N 2

Oxygen O 2

Argon Ar

Hydrogen H 2

Nitrous oxide N 2 o

N 2 O carbon monoxide CO

carbon dioxide CO 2

0.78084

0.20948

9.34×10 -3

5.0×10 -3

3.0×10 -3

1.0×10 -3

0.33×10 -3

0.0182×10 -3

MethaneCH 4

Krypton Kr

Xenon Xe

Ozone O 3

NO 2

Ammonia NH 3

Sulfur dioxide SO 2

5.24×10 -6

1.6×10 -6

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com