SF6 equipment leakage rate monitoring system and method

A monitoring system, SF6 technology, applied in the direction of comprehensive factory control, instruments, measuring devices, etc., can solve the waste of manpower and material resources, poor construction technology, operation and maintenance personnel can not accurately judge the time node when the air pressure of the leaking equipment reaches the alarm value and other issues to achieve the effect of enhancing the level of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

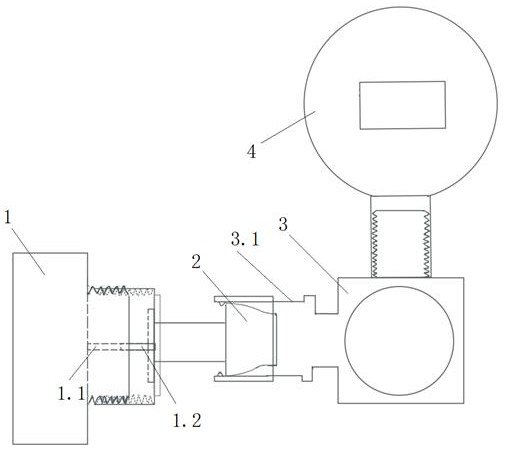

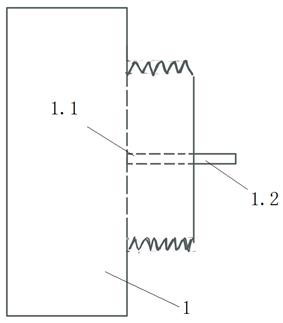

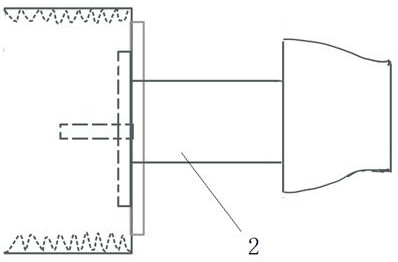

[0056] The following will clearly and completely describe the technical solutions in the embodiments with reference to the drawings in the embodiments of the application. Obviously, the described embodiments are only some of the embodiments of the application, not all of them. Based on the embodiments, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present application.

[0057] Unless otherwise defined, the technical terms or scientific terms used in the embodiments of the present application shall have the usual meanings understood by those skilled in the art. "First", "second" and similar words used in this embodiment do not indicate any order, quantity or importance, but are only used to distinguish different components. "Comprising" or "comprising" and similar words mean that the elements or items appearing before the word include the elements or items listed after the word and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com