Manufacturing method of ultrathin high-temperature-resistant solid-state capacitor

A manufacturing method and high temperature resistant technology, applied in the manufacturing field of ultra-thin high temperature resistant solid capacitors, can solve the problems of poor temperature resistance and life, and achieve the effect of reducing the aging speed and improving the temperature resistance and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

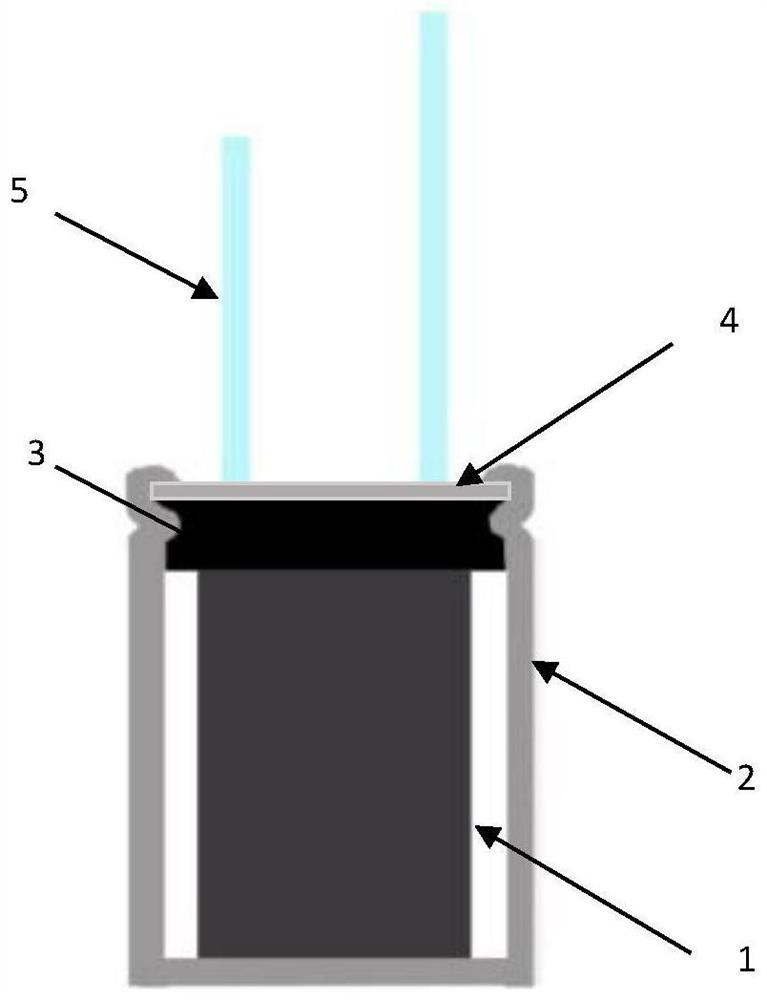

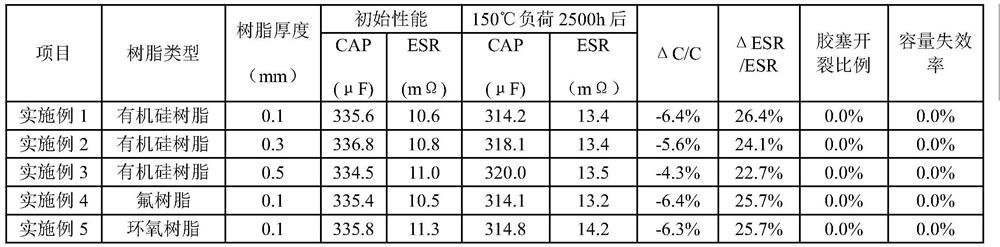

[0024] This specific embodiment is a manufacturing method of an ultra-thin high temperature resistant solid capacitor, the basic model of which is Φ6.3×4.5 (2.5V330μF), and the specific steps are as follows:

[0025] (1) Nail the guide pins to the anode foil and the cathode foil, separate them with an isolation layer, wind them into a core, wrap them with tape to fix them, and cover them with a rubber stopper coated with a silicone resin with a thickness of 0.1 mm;

[0026] (2) Immerse the core in the chemical liquid, apply voltage to repair and dry;

[0027] (3) The core is impregnated with monomer and oxidant and then polymerized at high temperature to form a conductive polymer;

[0028] (4) Put the core into the aluminum shell and encapsulate;

[0029] (5) The packaged products are aged and sorted, and the base plate is added to make surface-mount solid capacitor products.

Embodiment 2

[0031] Different from Example 1 is a rubber stopper coated with silicone resin with a thickness of 0.3 mm.

Embodiment 3

[0033] Different from Example 1 is a rubber stopper coated with a silicone resin with a thickness of 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com