Engine oil and fuel oil purifier and using method thereof

A technology of oil purifier and engine oil, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of three-way catalytic converter lead poisoning, irreversibility and recovery, and affect the performance of automobiles, so as to avoid environmental pollution, Improved service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

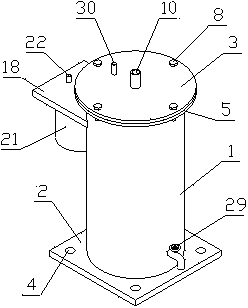

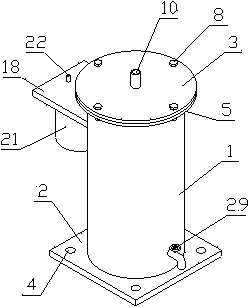

[0053] Such as figure 1 , figure 2 , Figure 7 , Figure 8 , Figure 12 and Figure 14 ~ Figure 16 As shown, the engine oil and fuel oil purifier includes an oil purifier main body 1, a base 2 and an oil purifier cover 3, the bottom of the oil purifier main body 1 is arranged in the middle of the base 2, and the base 2 is installed on the vehicle body through the mounting hole 4 , the top of the oil purifier main body 1 is provided with a mounting edge 5, and the oil purifier main body 1 is connected to the oil purifier cover 3 through the bolt 8, the mounting hole 2 6 on the mounting edge 4, the mounting hole 3 7 on the oil purifier cover 3, and the nut 9 Installed together, an oil delivery pipe 10 is vertically provided on the oil purification cover 3, the bottom of the oil delivery pipe 10 is 15-25mm away from the bottom of the oil purifier main body 1, the top of the oil delivery pipe 10 extends to the outside of the oil purification cover 3, the top of the oil delive...

Embodiment 2

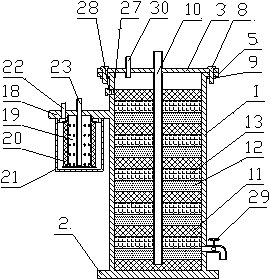

[0060] Such as image 3 , Figure 4 , Figure 7 , Figure 8 , Figure 11 and Figure 14 ~ Figure 16As shown, the engine oil and fuel oil purifier includes an oil purifier main body 1, a base 2 and an oil purifier cover 3, the bottom of the oil purifier main body 1 is arranged in the middle of the base 2, and the base 2 is installed on the vehicle body through the mounting hole 4 , the top of the oil purifier main body 1 is provided with a mounting edge 5, and the oil purifier main body 1 is connected to the oil purifier cover 3 through the bolt 8, the mounting hole 2 6 on the mounting edge 4, the mounting hole 3 7 on the oil purifier cover 3, and the nut 9 Installed together, an oil delivery pipe 10 is vertically provided on the oil purification cover 3, the bottom of the oil delivery pipe 10 is 15-25mm away from the bottom of the oil purifier main body 1, the top of the oil delivery pipe 10 extends to the outside of the oil purification cover 3, the top of the oil deliver...

Embodiment 3

[0067] Such as Figure 5 , Figure 6 , Figure 9 , Figure 10 and Figure 13 As shown, the engine oil and fuel oil purifier includes an oil purifier main body 1, a base 2 and an oil purifier cover 3, the bottom of the oil purifier main body 1 is arranged in the middle of the base 2, and the base 2 is installed on the vehicle body through the mounting hole 4 , the top of the oil purifier main body 1 is provided with a mounting edge 5, and the oil purifier main body 1 is connected to the oil purifier cover 3 through the bolt 8, the mounting hole 2 6 on the mounting edge 4, the mounting hole 3 7 on the oil purifier cover 3, and the nut 9 Installed together, the oil delivery pipe 10 is vertically arranged on the oil purification cover 3, the bottom of the oil delivery pipe 10 is 15-25mm away from the bottom of the oil purifier main body 1, the top of the oil delivery pipe 10 extends to the outside of the oil purification cover 3, the top of the oil delivery pipe 10 is an elbow,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com