Combined diesel motor rotor workpiece and assembling method thereof

A motor rotor and combined technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of unfavorable automatic assembly, loose locking ring, etc., and achieve the effect of reasonable structural design and easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

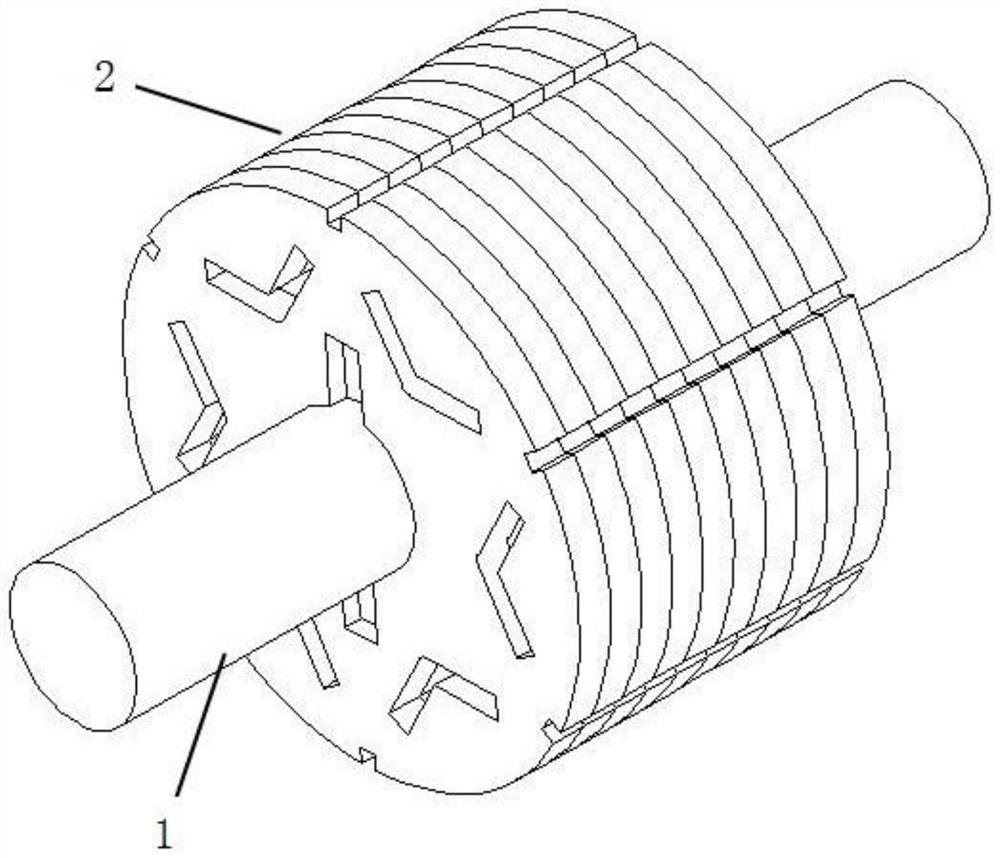

[0035] like Figure 1-Figure 6 As shown, this embodiment is a combined diesel motor rotor workpiece, including a rotating shaft 1 and a combined rotor core 2:

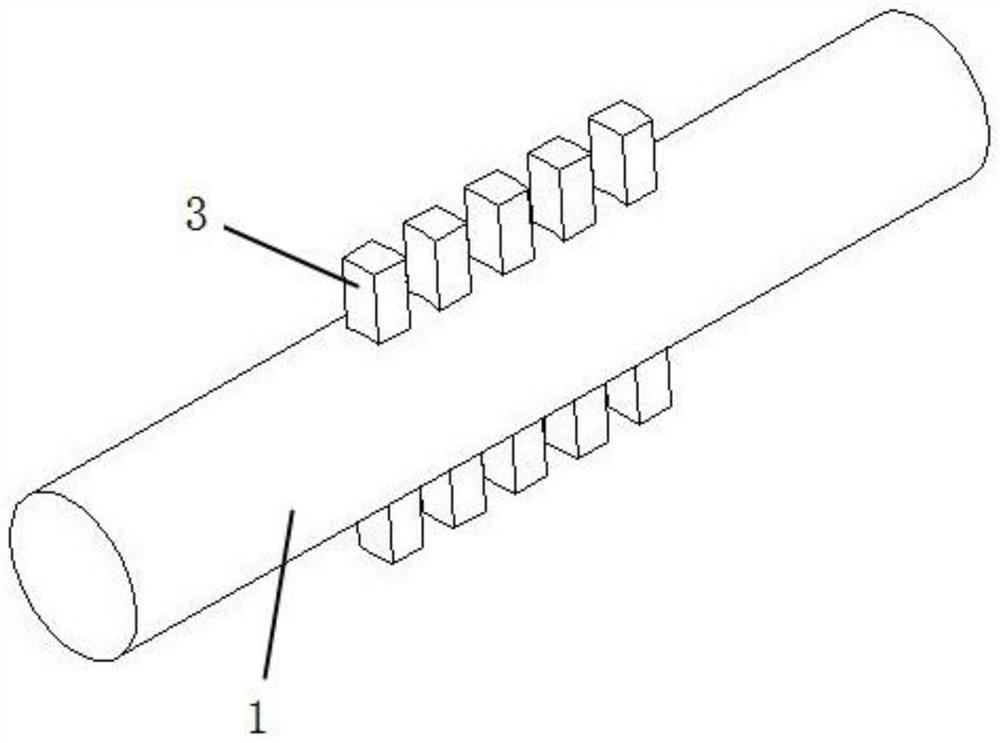

[0036] In this embodiment, a plurality of pegs 3 are arranged on the rotating shaft 1 side by side, and the rotating shaft 1 and the pegs 3 are integrally formed.

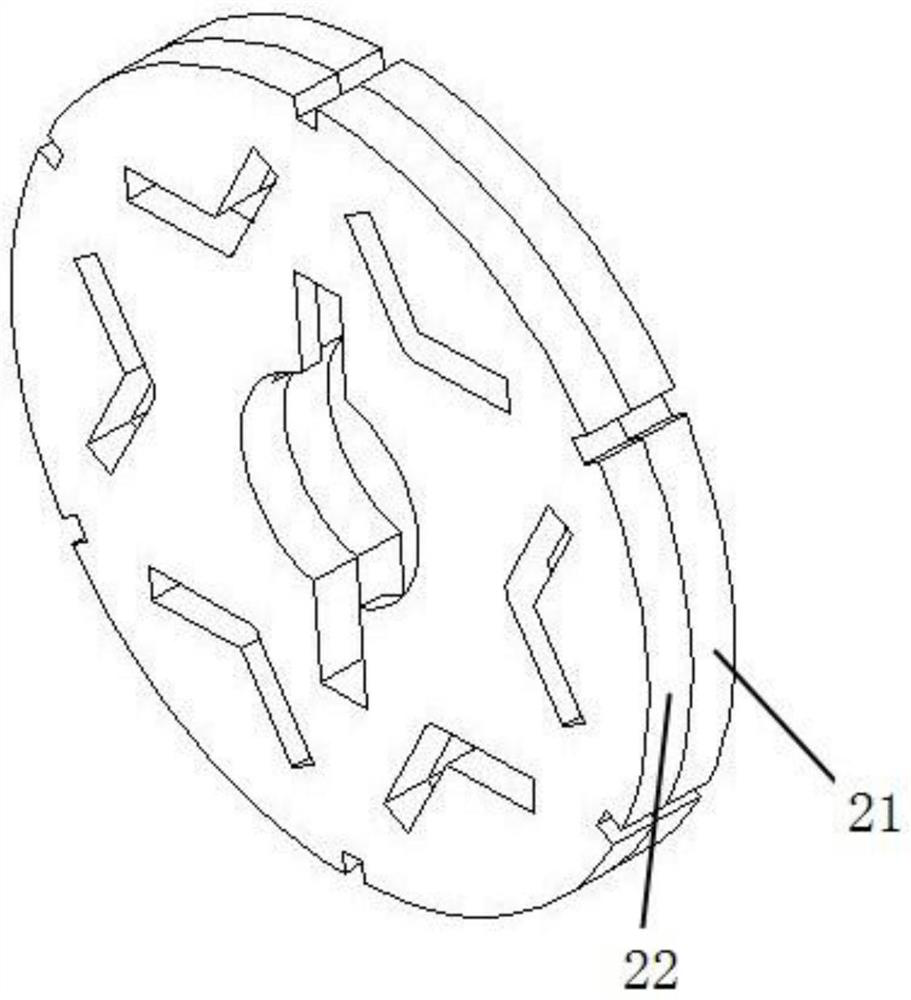

[0037] In this embodiment, the combined rotor core 2 is composed of several groups of splicing blocks arranged side by side, and each group of splicing blocks is formed by butting a splicing block I 21 and a splicing block II 22 with symmetrical structures. The splicing block I 21 and the splicing block II 22 each include a sheet body 211 , and the sheet body 211 is provided with a central through hole 212 , an introduction hole 213 , a movable slot 214 , a permanent magnet mounting hole 215 and a welding slot 216 . The center of the sheet body 211 is provided with a central through hole 212, the introduction hole 213 and the movable slot 214 are symmetric...

Embodiment 2

[0047] The structure of the present embodiment is basically the same as that of the first embodiment, the difference lies in that the rotating shaft and the dial column are of separate structures, and the rotating shaft is provided with sockets for inserting the dial column side by side.

Embodiment 3

[0049] The structure of this embodiment is basically the same as that of the first embodiment, and the difference lies in that the central angle of the movable groove is 45 degrees.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap