Floatation separator of waste plastics

A separation device and technology for waste plastics, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve unfavorable large-scale continuous production of waste plastics recycling, low separation efficiency, high labor intensity, etc. problems, to achieve the effect of simple structure, continuous separation process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

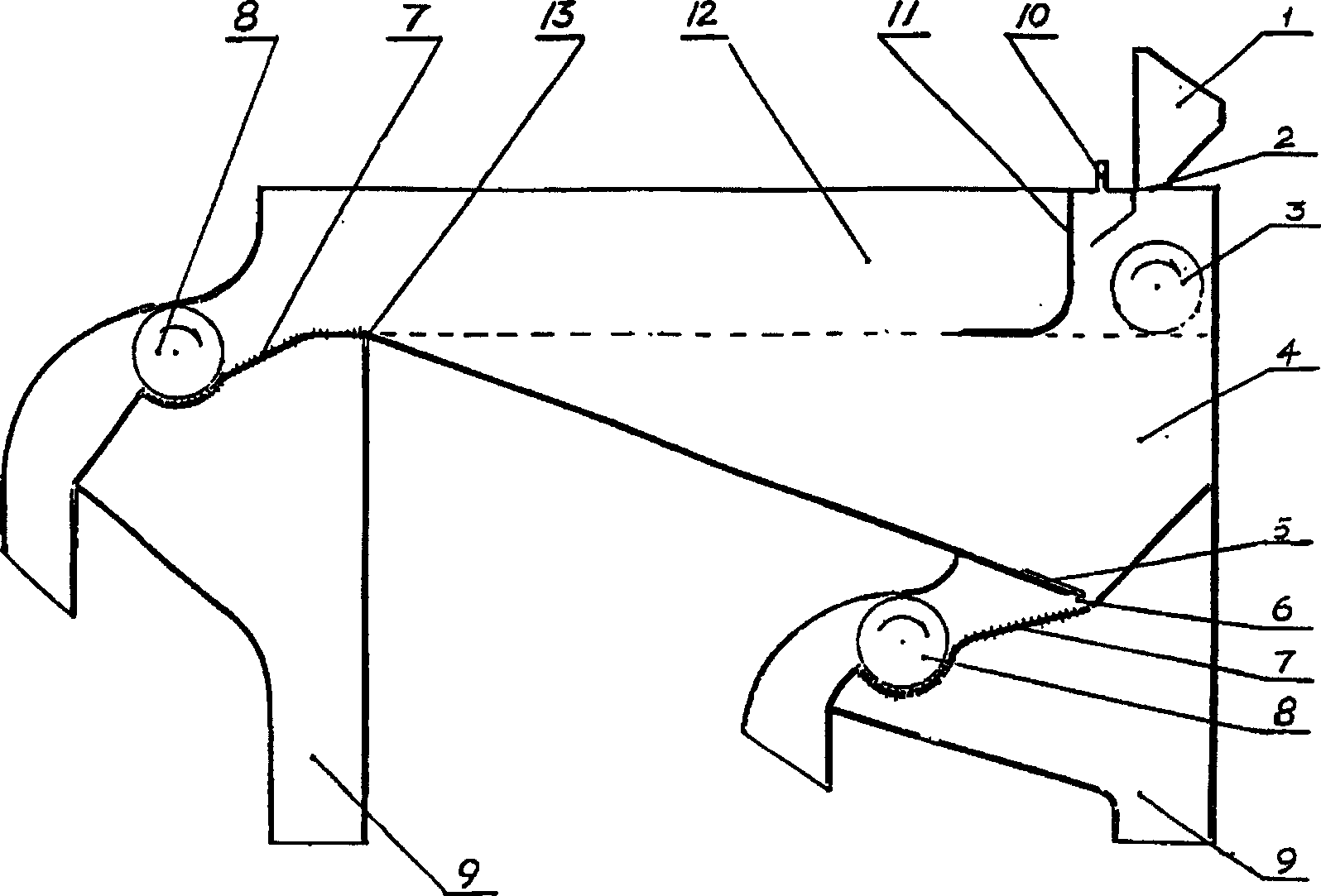

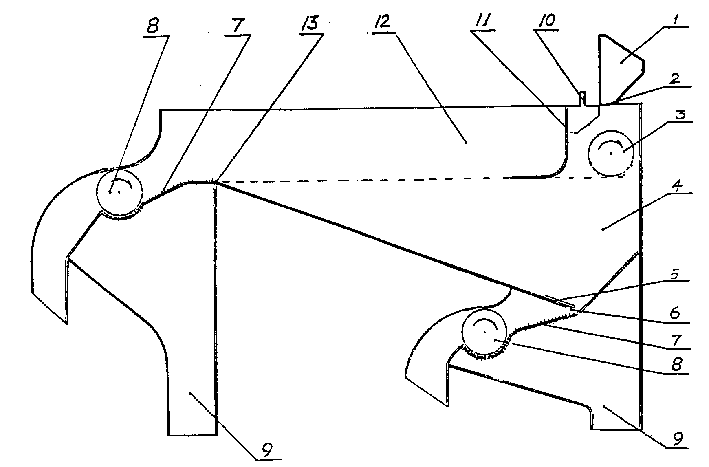

[0017] Further describe the present invention with embodiment below in conjunction with accompanying drawing, the scope of the present invention is not limited by these embodiments. The scope of the present invention is set forth in the claims.

[0018] Such as figure 1 In the shown flotation separation device, the aspect ratio of the separation box 12 is 4. The separation liquid 4 is housed in the separation box 12 . A feed inlet 2 is arranged above one end of the separation box 12 , and a hopper 1 is connected above the feed inlet 2 . A liquid inlet 10 for circulating the separation liquid is provided next to the feed inlet 2 . A stirring wheel 3 is arranged below the feeding port 2 and on the liquid surface of the separating liquid. The central axis of the stirring wheel 3 is parallel to the liquid surface of the separating liquid. The rotational speed of the stirring wheel 3 is 300 rpm. The part of the paddle of the stirring wheel 3 that is not in the liquid surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com