Automatic sorting equipment for photovoltaic glass

A technology for automatic sorting of photovoltaic glass, applied in the direction of sorting, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve problems such as damage to photovoltaic panels, weak suction cups and photovoltaic glass adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

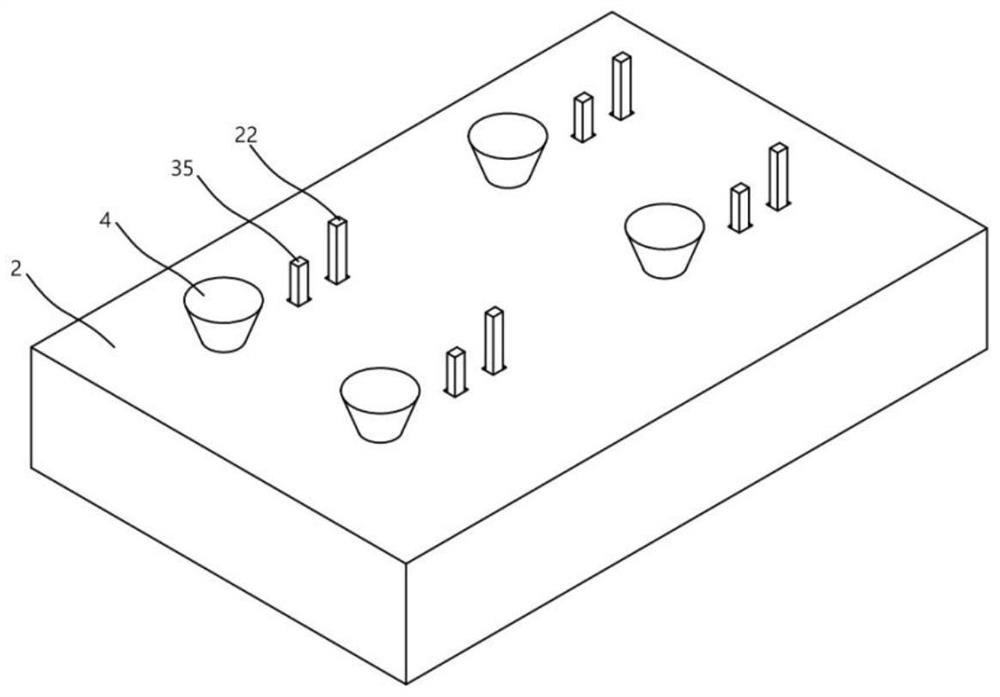

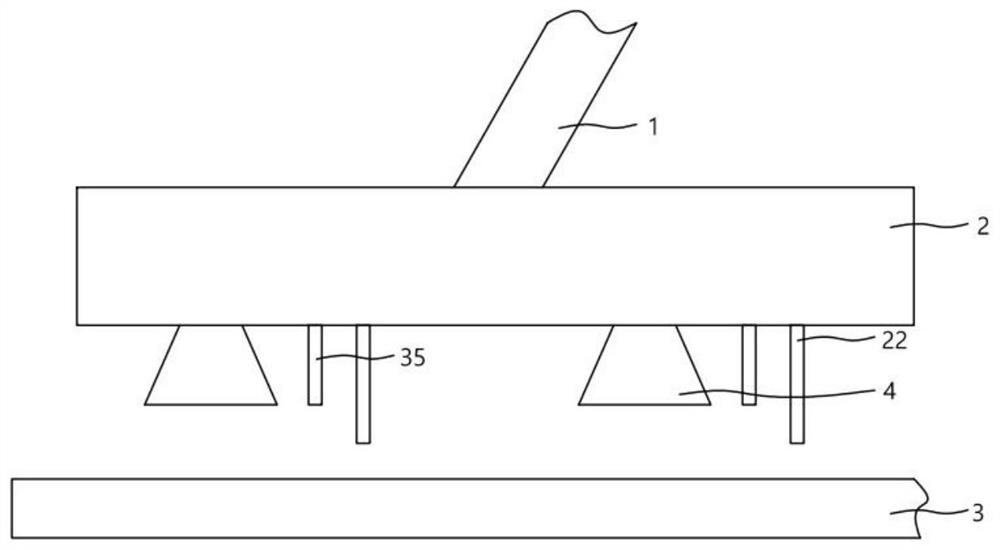

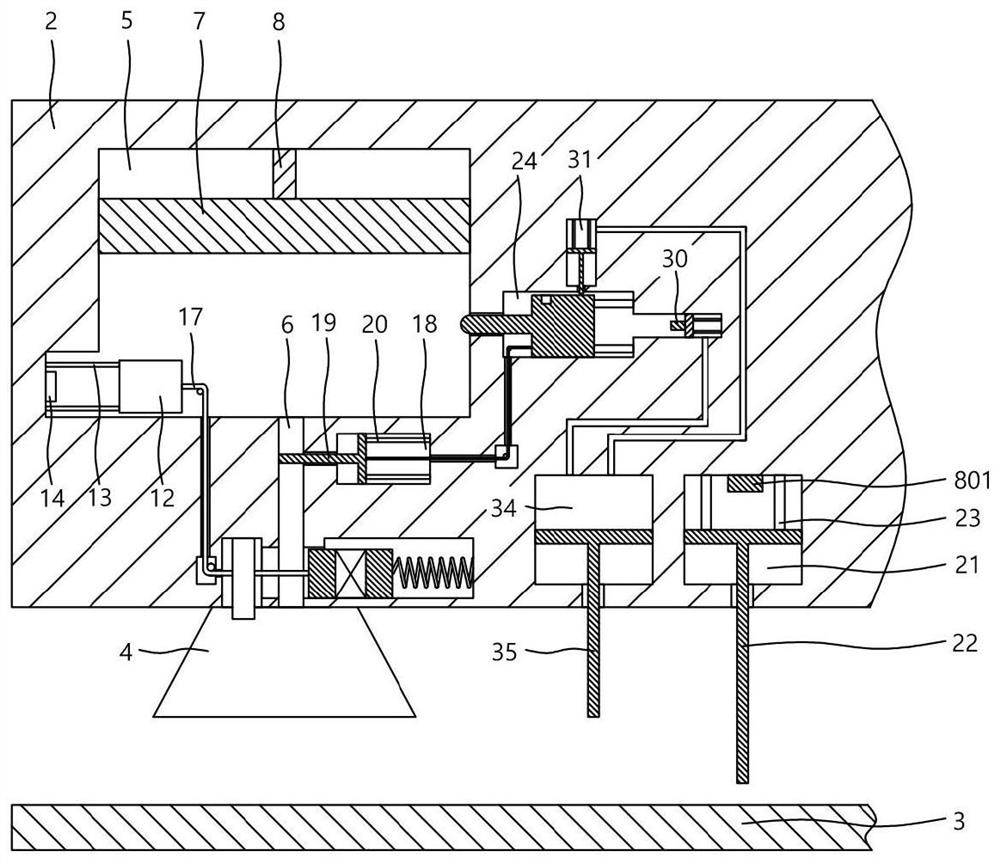

[0034] An automatic sorting device for photovoltaic glass, including a mechanical arm 1, which is used to drive the fixed box 2 to move, and the mechanical arm 1 is driven by a computer to drive the fixed box 2 to perform actions such as rising, falling, and turning over. The fixed box 2 is fixedly connected with a number of suction cups 4 for fixing the photovoltaic glass 3. There are four suction cups 4 in this embodiment, and the suction cups 4 are arranged at the bottom of the fixed box 2. A closed cavity 5 is opened inside the fixed box 2. The closed cavity 5 and the sucker 4 are connected through the air passage 6, and the air passage 6 is movably blocked by the air-blocking assembly. The airtight plate 7 is movable inside the airtight cavity 5, and the airtight plate 7 and the inner wall of the airtight chamber 5 form an airtight space. When the airtight plate 7 During movement, the gas inside the airtight cavity 5 can be squeezed, and then discharged through the air cha...

Embodiment 2

[0038] On the basis of Embodiment 1, the structure of the air blocking assembly in Embodiment 1 is disclosed. The air blocking assembly includes an air blocking chamber 18 opened inside the fixed box 2, and the inside of the air blocking chamber 18 is provided with a movable block for blocking the air passage 6. The gas baffle 19, the gas baffle 19 and the inner wall of the air baffle chamber 18 are fixedly connected with the second elastic block 20, the gas baffle 19 blocks the air passage 6 when no external force is applied, and the air baffle 19 is driven out of the air passage 6 by the drive assembly In the initial state, the gas baffle 19 is in the state of blocking the air passage 6. In this embodiment, when the airtight plate 7 is moved through the setting of the drive assembly, the gas inside the airtight chamber 5 is first squeezed into high-pressure gas, and as the airtight plate 7 continuously moves down until the airtight plate 7 squeezes the subsequent drive rod 25...

Embodiment 3

[0040] On the basis of Embodiment 1, the control assembly in Embodiment 1 is disclosed. The control assembly includes a control chamber 21 opened inside the fixed box 2, and a first electrical connection with the telescopic rod 8 is fixed inside the control chamber 21. Switch 801, the first switch 801 is a pressure-contact switch. The first switch 801 is connected in series with the telescopic rod 8 and the external power supply through a wire. When the first switch 801 is squeezed, the telescopic rod 8 starts to continuously expand and contract when it is energized. The inside of the control chamber 21 is provided with an elastic rod 22 that is in movable contact with the photovoltaic glass 3 and the first switch 801. The elastic rod 22 cooperates with the first switch 801 to control the opening of the telescopic rod 8. The elastic rod 22 is fixedly connected to the inner wall of the control chamber 21 with a second Three elastic blocks 23, when the mechanical arm 1 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com