Sliding plate dismounting and mounting module and pantograph dismounting and mounting assembly line thereof

A technology of skateboard and sliding seat, which is applied in the field of pantograph auxiliary maintenance equipment and subway maintenance equipment, can solve the problems of no automatic equipment, time-consuming maintenance of pantographs, etc., to reduce maintenance costs and cycles, shorten maintenance cycles, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

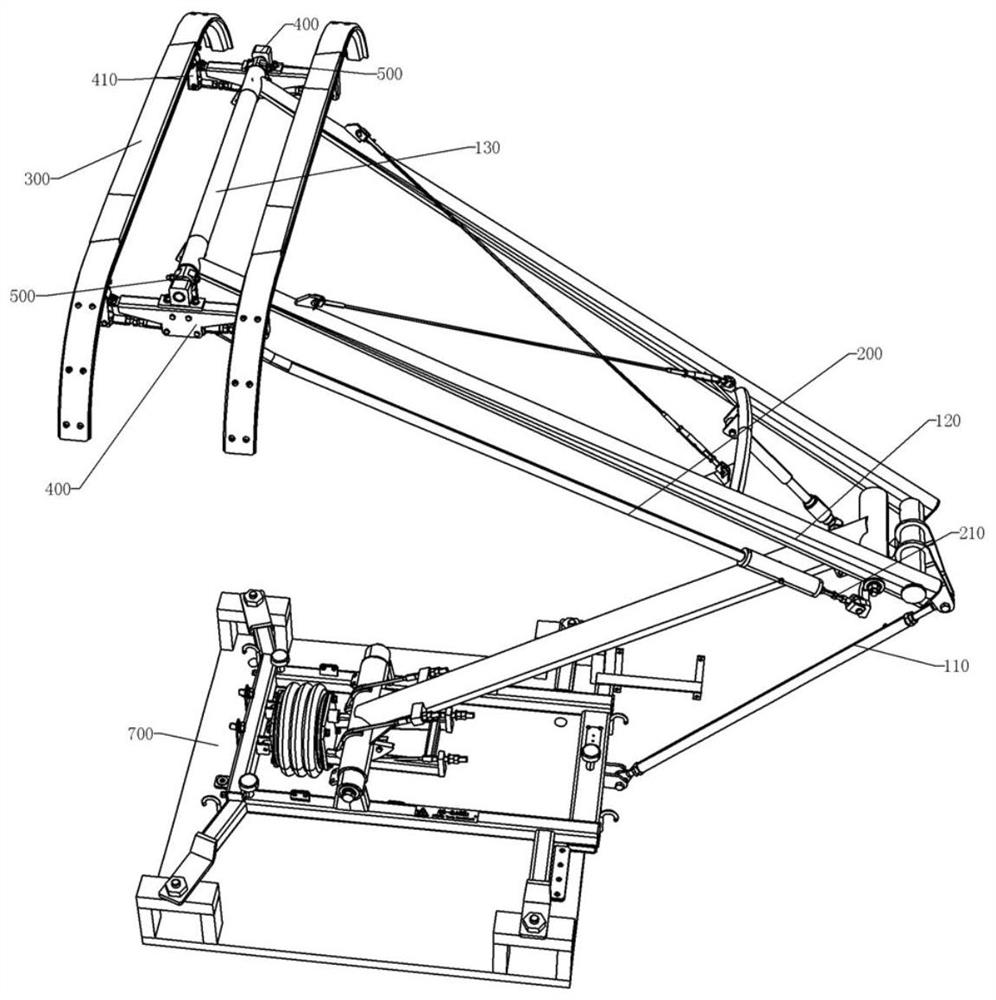

[0029] The present embodiment will carry out the automatic disassembly and assembly design for the above-mentioned process, thereby greatly reducing the time-consuming disassembly and assembly, and improving the efficiency.

[0031] The pantograph is installed on the conveying seat 700, and the conveying seat 700 is snapped and slidably installed on the conveying track 600

[0033] The screw sleeve longitudinal moving frame A140 can also be slidably installed with the screw sleeve transverse moving frame A150, the third screw sleeve electric cylinder A490,

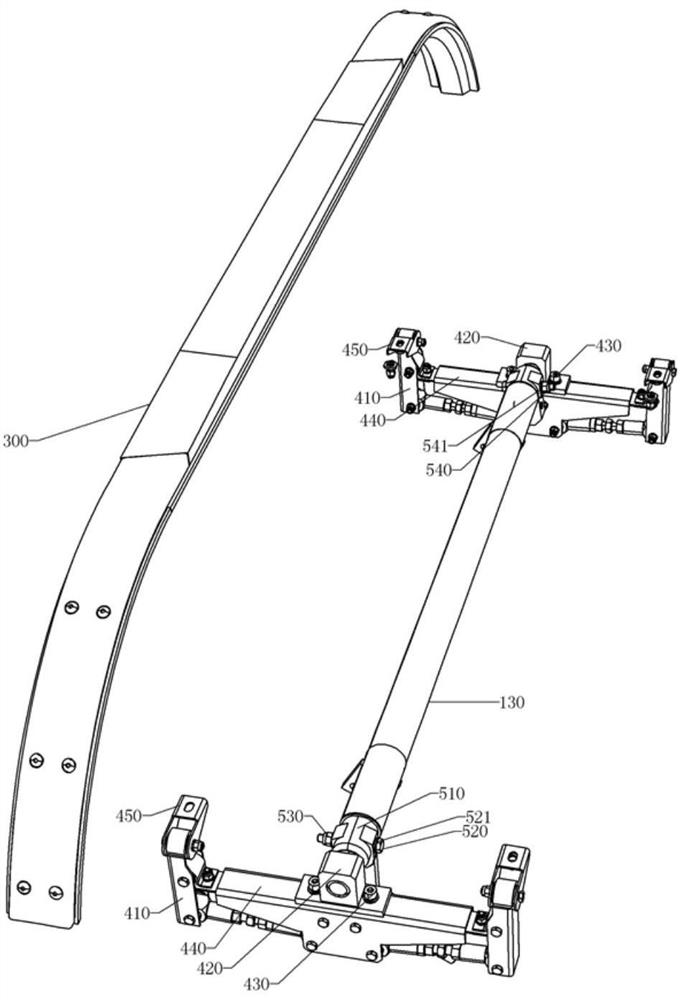

[0044] The first sliding plate sliding seat B411 and the second sliding sliding seat plate B412 are also respectively installed on the sliding plate sliding seat B410,

[0055] The first bolt disassembly and assembly mechanism D210 includes a first bolt frame D141 installed on the first disassembly and assembly frame D140.

[0056] A third guide shaft D163 is installed on the first clamping frame D150 in an axially slidable man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com