Multi-machine drive control system

A technology of drive control and speed regulating mechanism, applied in intelligent control system, underground belt drive in coal mining industry, high efficiency and safety field, can solve the problem of high professional quality requirements of coal miners, high price and maintenance cost, poor soft start effect, etc. problems, to achieve the effect of increasing the effective mining time, reducing maintenance costs, and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

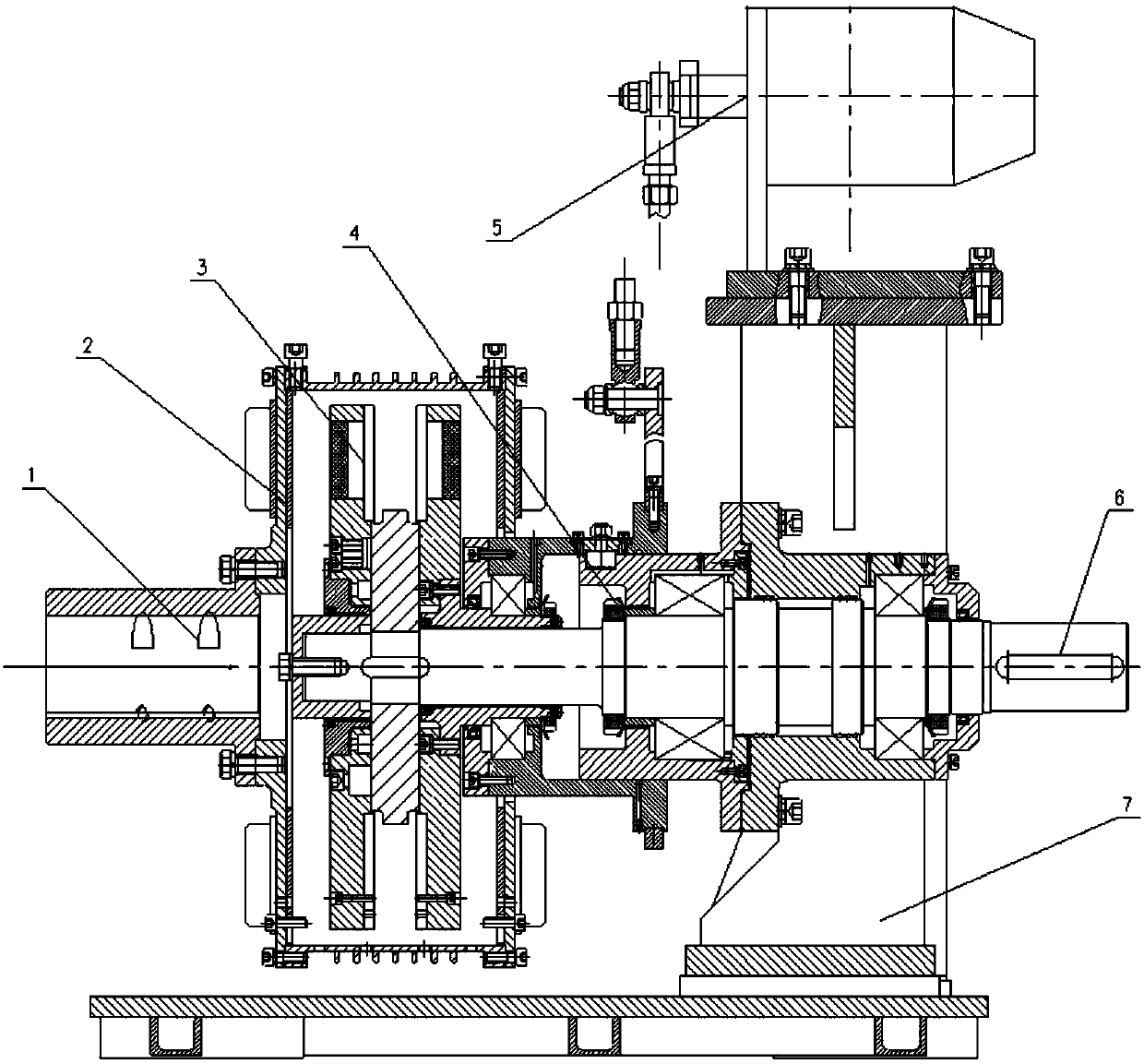

[0025] The present invention provides a multi-machine drive control system, which is characterized in that: the multi-machine drive control system includes an input coupling 1, a copper rotor assembly 2, a disk assembly 3, a speed regulating mechanism 4, and an electric actuator 5 , output shaft 6, base bracket 7;

[0026] Among them: the input coupling 1 is connected with the copper rotor assembly 2, the copper rotor assembly 2 is matched with the disk assembly 3, the speed regulating mechanism 4 is installed on the output shaft 6, the copper rotor assembly 2 and the disk assembly 3 are connected with the electric actuator 5, The output shaft 6 is installed on the base support 7 through a bearing assembly.

[0027] The copper rotor assembly 2 and the disk assembly 3 are mine magnetic couplings.

[0028] The multi-machine drive control system has an infrared temperature sensor installed on the side of the disk assembly 3 .

[0029] In the multi-machine drive control system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com