Multi-station full-automatic switching CNC machining equipment

A processing equipment, fully automatic technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of labor-intensive, prone to safety accidents, low efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

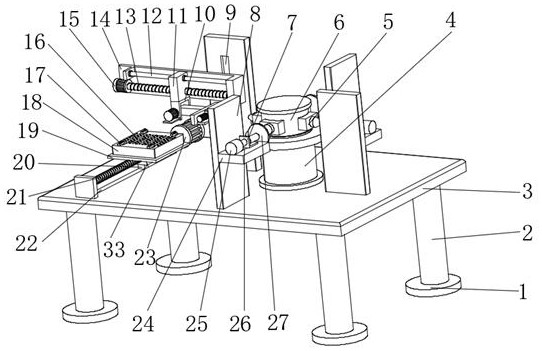

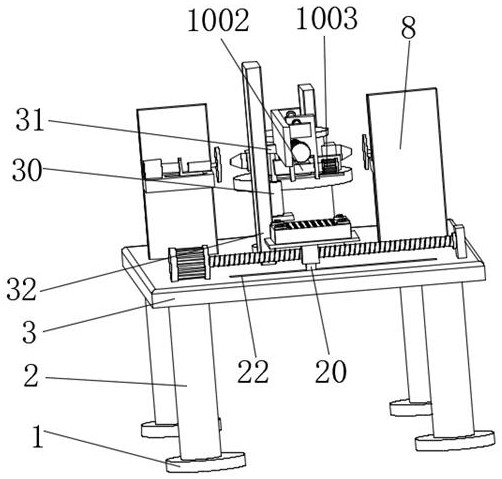

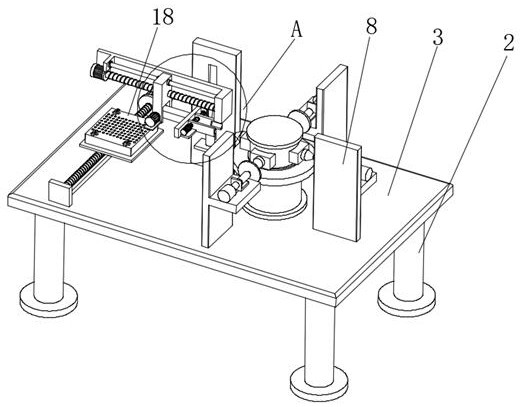

[0031] Such as Figures 1 to 8 As shown, the embodiment of the present invention provides a multi-station automatic switching CNC processing equipment, including a workbench 3, the upper surface of the workbench 3 is fixedly installed with an installation cylinder 4, and the inner surface of the installation cylinder 4 is fixedly installed with a third Motor 28, the output end of the third motor 28 is equipped with a turntable 6, the side is fixed with a number of limit fixtures 5, the upper surface of the workbench 3 is fixed with a number of backing boards 8, the front surface of the backing board 8 A hydraulic cylinder support plate 24 is fixedly installed, and a mounting plate 7 is installed at the output end of the hydraulic cylinder support plate 24, and the mounting plate 7 is slidably mounted on the upper surface of the hydraulic cylinder support plate 24, and a grinding disc is installed on the mounting plate 7 27. A conveying plate 32 is fixedly installed on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com