Solid waste conveying device

A conveying device and conveyor belt technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of odor overflow, inability to achieve full sealing, material leakage, etc., and achieve space saving, good air tightness, and reasonable The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

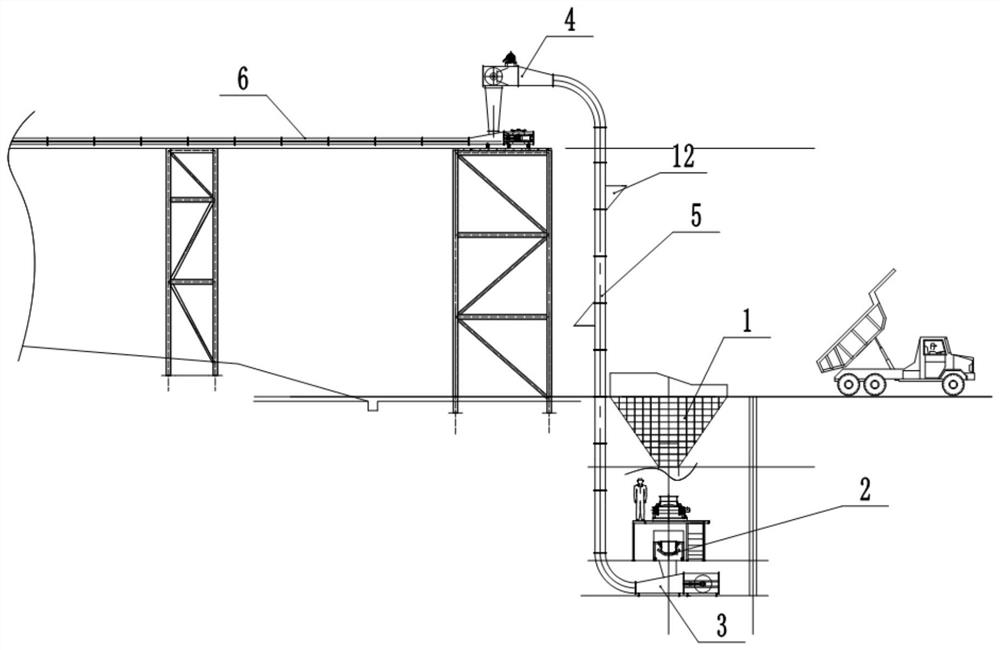

[0035] The embodiment is basically as attached figure 1 with figure 2 Shown: a solid waste conveying device, including a conveying belt 5, a conveying track and a driving unit, the conveying track is Z-shaped, the driving unit drives the conveying belt 5 to convey along the Z-shaped conveying track, and a lifting bucket 12 is connected to the conveying track. The solid waste conveying device in this embodiment further includes a first housing 9 , and both the conveying belt 5 and the conveying track are located in the first housing 9 .

[0036] Conveyor belt 5 comprises vertical section and two horizontal sections, and two horizontal sections are positioned at the top end and the bottom of vertical section respectively, and conveyer belt 5 has two turnings greater than or equal to 90 ° in the present embodiment, and conveyer belt 5 The horizontal section below is the feed end 3 , the horizontal section above the conveyor belt 5 is the discharge end 4 , and a belt conveyor 6 ...

Embodiment 2

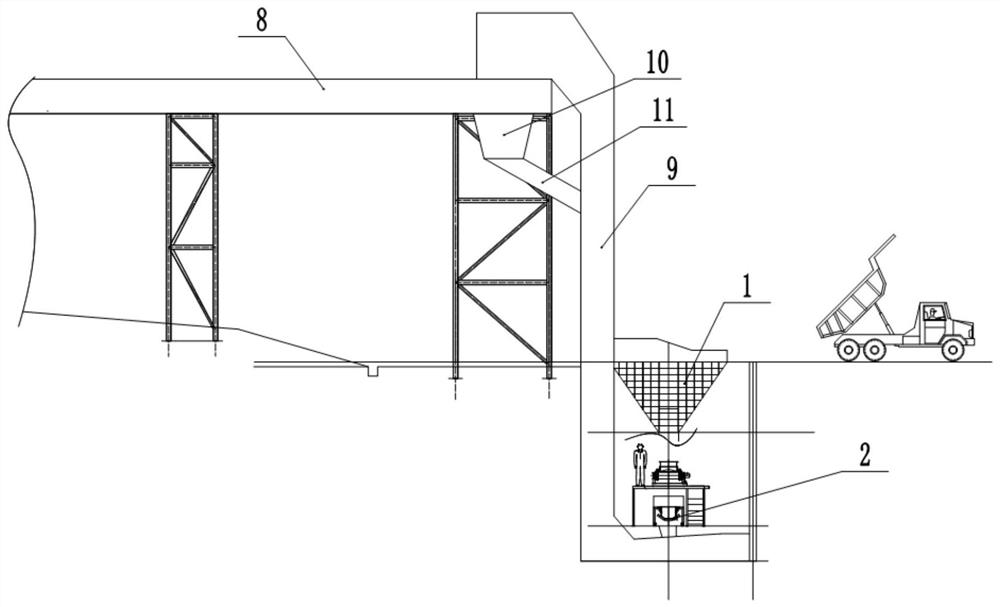

[0049] Such as Figure 5 As shown, a solid waste conveying device differs from Embodiment 1 in that: the material guide box 11 in this embodiment is in a spiral shape, and the end of the material guide box 11 away from the collecting hopper 10 faces the conveyor belt 5 to lift the material. side.

[0050] In this embodiment, the spiral material guide box 11 can prolong the falling path of the material, thereby slowing down the falling speed of the material, and preventing the material from falling too fast to be conveyed by the lifting bucket 12 . In addition, in this embodiment, the material guide box 11 is in a spiral shape, which can change the direction in which the material falls, so that the material can fall to the side where the material is lifted by the conveyor belt 5, so that it is convenient to directly fall to the lifting machine that is located in the vertical section and is being transported upwards. In the bucket 12, it is convenient to directly transport the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com