Natural rubber chloroprene rubber composition for seawater-resistant rubber support as well as preparation method and application of natural rubber chloroprene rubber composition

A technology of rubber bearing and natural rubber, applied in the field of natural rubber neoprene composition, can solve the problems of poor low temperature performance, high cost of neoprene, poor processing performance, etc., to reduce swelling rate, improve aging resistance and Saltwater resistance, effects of improving aging resistance and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

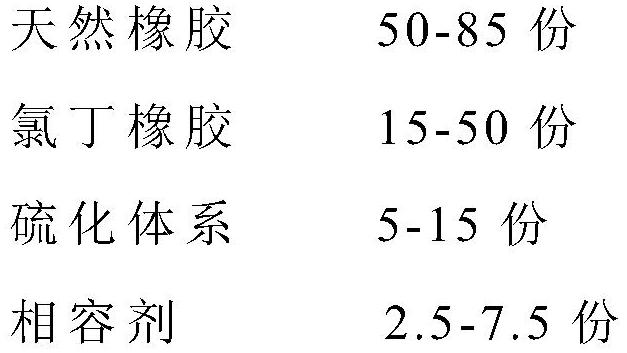

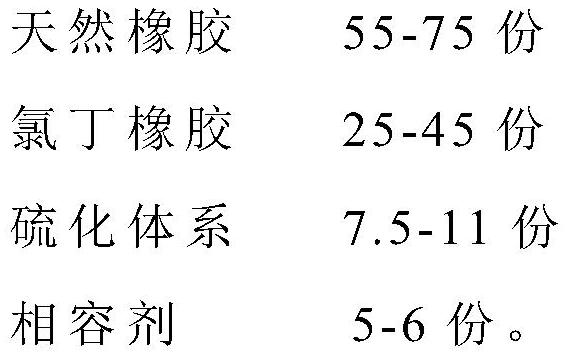

[0034] This example provides a natural rubber neoprene composition for seawater-resistant rubber bearings, and its components are shown in Table 1.

[0035] Among them, the composition of 1# vulcanization system is: 1 part of sulfur, 5 parts of zinc oxide, 2 parts of magnesium oxide, 2 parts of accelerator DM; the composition of 2# vulcanization system is: 1 part of DCP, 5 parts of zinc oxide, 2 parts of magnesium oxide, accelerator Agent Na-22 2 parts.

[0036] The mixing process is as follows:

[0037] The rubber is mixed in an internal mixer in two stages. The initial temperature of the mixing chamber was 70°C, and the speed of the mixing rotor was 40r / min.

[0038] The one-stage mixing process is as follows: add chloroprene rubber and natural rubber raw rubber into the internal mixer at the same time, and after mixing for 2 minutes, add anti-aging agent, softener, acid absorber, and carbon black in sequence. Mixed for 5 minutes, the mixing temperature reached 110 degree...

Embodiment 2

[0041] This example provides a natural rubber neoprene composition for seawater-resistant rubber bearings, the preparation process of which is basically the same as in Example 1, the only difference being that the components of the composition are different, see Table 1 for details.

Embodiment 3

[0043] This example provides a natural rubber neoprene composition for seawater-resistant rubber bearings, the preparation process of which is basically the same as in Example 1, the only difference being that the components of the composition are different, see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com