Compound cold galvanized coating

A cold galvanizing and coating technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of low anti-corrosion durability, environmental protection and ease of use, etc., achieve good cathodic protection, improve barrier protection, and resist. Excellent effect of salt spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

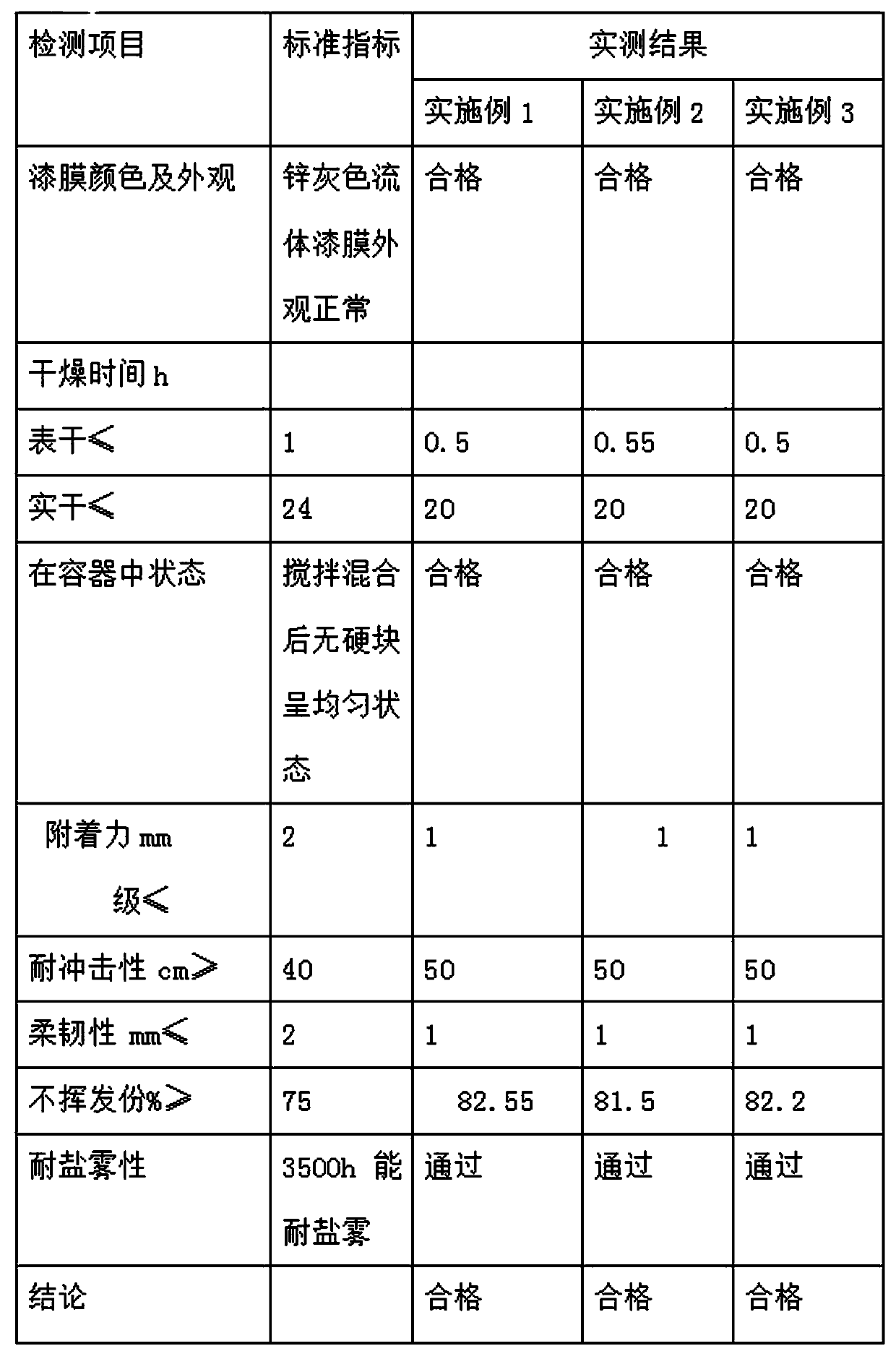

Examples

Embodiment 1

[0026] (1) The synthesis steps of modified acrylic resin are as follows:

[0027] a. The monomer is added into the monomer preparer through a filter, mixed evenly and put into the dropper for use;

[0028] B, the initiator is dropped into the initiator dissolver for dissolving, placed layered, separated from water for subsequent use, the initiator is benzoyl peroxide and cumene hydroperoxide, and the consumption of benzoyl peroxide is 0.8-1.2 parts, The consumption of cumene hydroperoxide is 0.33-0.73 part;

[0029] c. When the kettle is empty, inert gas is introduced to drive away the air in the kettle in advance, and then the solvent is put in according to the formula. The inert gas is nitrogen, the solvent is toluene and butyl acetate, the amount of toluene is 38.27-40.27 parts, and the amount of butyl acetate is for 9-11 servings;

[0030] d. Turn on the stirring, turn on the steam valve for heating, and turn on the cooling water. When the temperature rises to about 20°C...

Embodiment 2

[0036] (1) The synthesis steps of modified acrylic resin are as follows:

[0037] a. The monomer is added into the monomer preparer through a filter, mixed evenly and put into the dropper for use;

[0038] B, the initiator is dropped into the initiator dissolver for dissolving, placed layered, separated from water for subsequent use, the initiator is benzoyl peroxide and cumene hydroperoxide, and the consumption of benzoyl peroxide is 0.8-1.2 parts, The consumption of cumene hydroperoxide is 0.33-0.73 part;

[0039] c. When the kettle is empty, inert gas is introduced to drive away the air in the kettle in advance, and then the solvent is put in according to the formula. The inert gas is nitrogen, the solvent is toluene and butyl acetate, the amount of toluene is 38.27-40.27 parts, and the amount of butyl acetate is for 9-11 servings;

[0040] d. Turn on the stirring, turn on the steam valve for heating, and turn on the cooling water. When the temperature rises to about 20°C...

Embodiment 3

[0046] (1) The synthesis steps of modified acrylic resin are as follows:

[0047] a. The monomer is added into the monomer preparer through a filter, mixed evenly and put into the dropper for use;

[0048] B, the initiator is dropped into the initiator dissolver for dissolving, placed layered, separated from water for subsequent use, the initiator is benzoyl peroxide and cumene hydroperoxide, and the consumption of benzoyl peroxide is 0.8-1.2 parts, The consumption of cumene hydroperoxide is 0.33-0.73 part;

[0049] c. When the kettle is empty, inert gas is introduced to drive away the air in the kettle in advance, and then the solvent is put in according to the formula. The inert gas is nitrogen, the solvent is toluene and butyl acetate, the amount of toluene is 38.27-40.27 parts, and the amount of butyl acetate is for 9-11 servings;

[0050] d. Turn on the stirring, turn on the steam valve for heating, and turn on the cooling water. When the temperature rises to about 20°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com