Graphene-based/montmorillonite-modified polyurethane floor material and preparation method thereof

A floor material and polyurethane technology, applied in the field of material chemistry, can solve the problems of inability to remove free isocyanate and affect the mechanical properties of floor materials, and achieve the effect of good chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

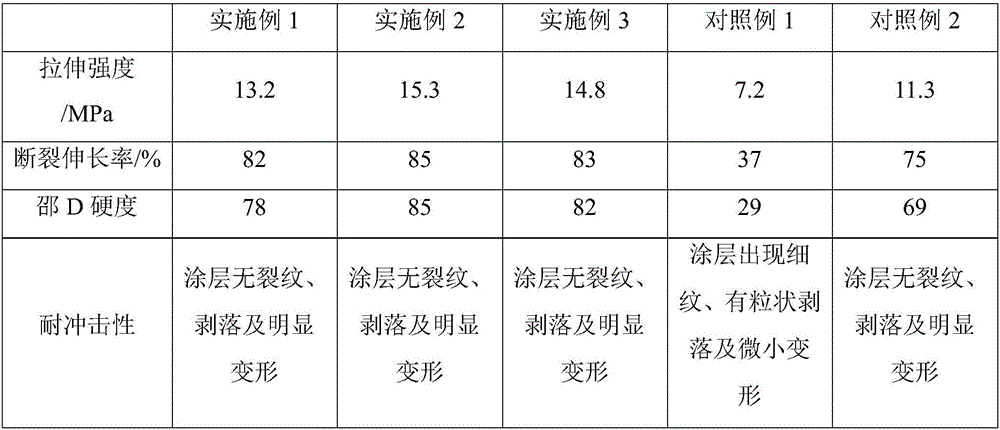

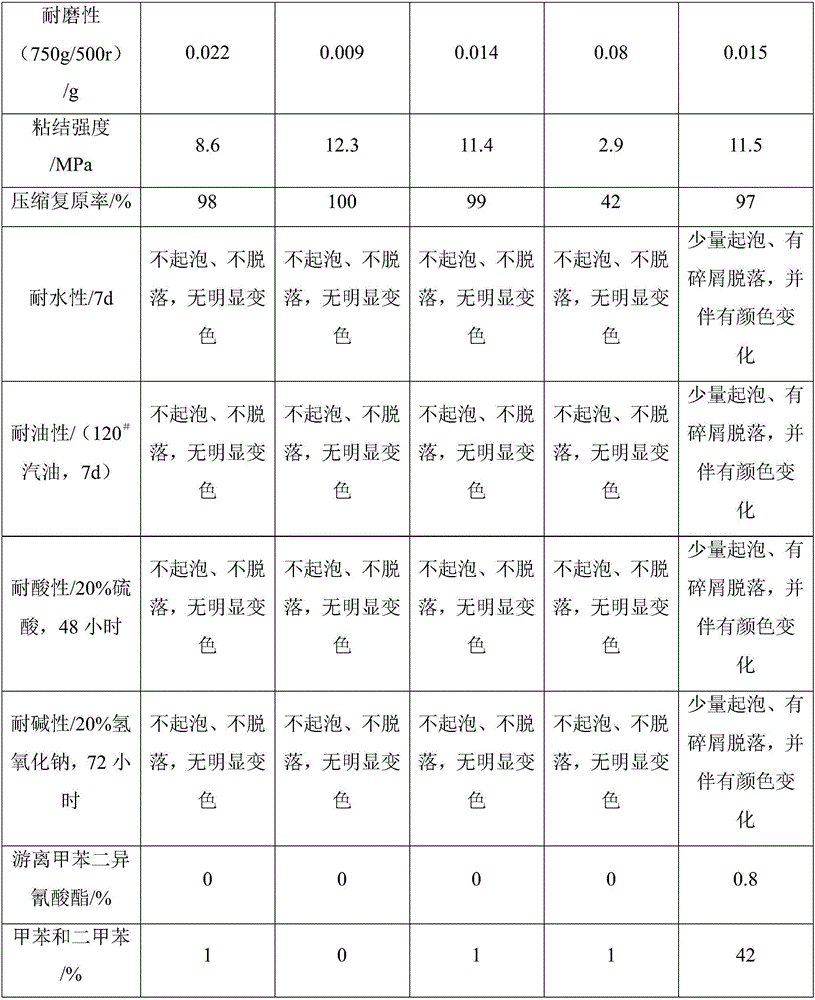

Examples

Embodiment 1

[0024] A polyurethane floor material based on graphene / montmorillonite modification, which is composed of the following components in proportion by weight: 27 parts of polyurethane, 7 parts of isocyanate, 3 parts of defoaming agent, 1 part of wetting and dispersing agent, water absorption 1 part of agent, 1 part of catalyst, 6 parts of graphene, 8 parts of montmorillonite, 3 parts of ferric chloride, 3 parts of sodium carbonate, 3 parts of hydrochloric acid, and 8 parts of borax.

[0025] A preparation method based on graphene / montmorillonite modified polyurethane flooring material, comprising the following steps:

[0026] (1) Preparation of the floor material matrix: Add polyurethane and isocyanate into the internal mixer, the blending temperature is 75°C, and the blending time is 45 minutes. After cooling down to 55°C, add ethanol dropwise, stir and mix well, and then add disinfectant Foaming agent and wetting and dispersing agent, and keep warm at 42°C for 8 hours;

[0027...

Embodiment 2

[0033] A polyurethane floor material based on graphene / montmorillonite modification, which is composed of the following components in proportion by weight: 38 parts of polyurethane, 11 parts of isocyanate, 5 parts of defoaming agent, 3 parts of wetting and dispersing agent, water absorption 3 parts of agent, 2 parts of catalyst, 13 parts of graphene, 14 parts of montmorillonite, 8 parts of ferric chloride, 9 parts of sodium carbonate, 13 parts of hydrochloric acid, and 14 parts of borax.

[0034] A preparation method based on graphene / montmorillonite modified polyurethane flooring material, comprising the following steps:

[0035] (1) Preparation of the floor material matrix: Add polyurethane and isocyanate into the internal mixer, the blending temperature is 86°C, and the blending time is 56 minutes. After cooling down to 65°C, add ethanol dropwise, stir and mix well, and then add disinfectant Foaming agent and wetting and dispersing agent, and keep warm at 52°C for 10 hours;...

Embodiment 3

[0042] A polyurethane floor material modified based on graphene / montmorillonite, which is composed of the following components in proportion by weight: 47 parts of polyurethane, 14 parts of isocyanate, 6 parts of defoaming agent, 4 parts of wetting and dispersing agent, water absorbing 6 parts of agent, 4 parts of catalyst, 18 parts of graphene, 17 parts of montmorillonite, 11 parts of ferric chloride, 12 parts of sodium carbonate, 17 parts of hydrochloric acid, and 19 parts of borax.

[0043] A preparation method based on graphene / montmorillonite modified polyurethane flooring material, comprising the following steps:

[0044] (1) Preparation of the floor material matrix: Add polyurethane and isocyanate into the internal mixer, the blending temperature is 92°C, and the blending time is 60 minutes. After cooling down to 70°C, add ethanol dropwise, stir and mix well, and then add disinfectant Foaming agent and wetting and dispersing agent, and keep warm at 58°C for 13 hours;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com