Cast-in-place concrete blocking method for beam-column joint part

A technology of beam-column joints and concrete, which is applied to the processing of building materials, construction, building reinforcements, etc., can solve problems such as quality defects, inconvenient construction, lack of lateral extrusion, etc., and achieve reliable blocking effect, simple and convenient construction, The effect of solving quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

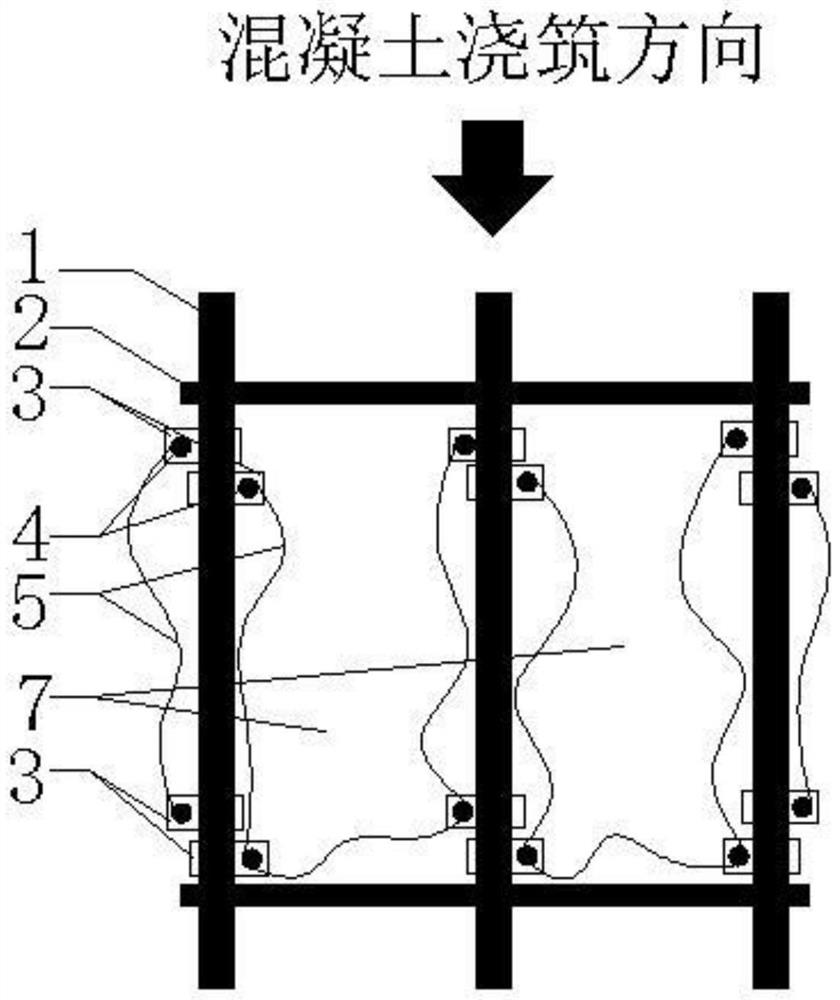

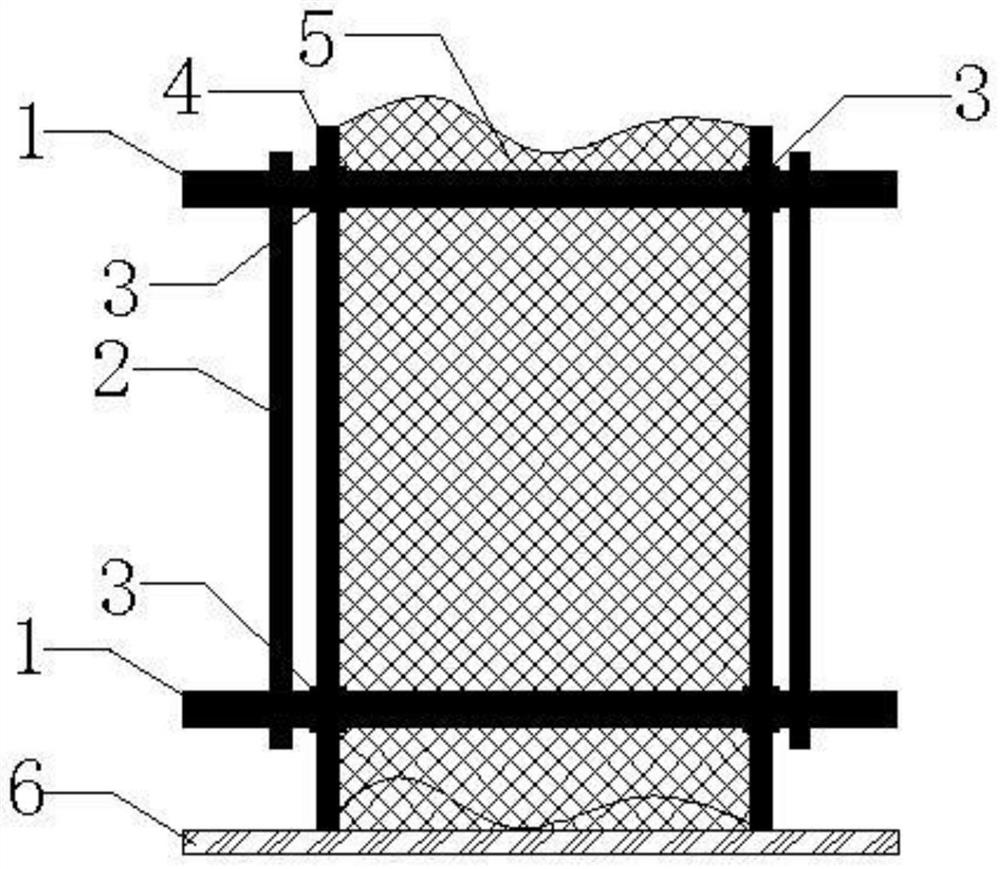

[0027] As shown in the accompanying drawings, a blocking method of cast-in-situ concrete at the joints of beams and columns is constructed by using a steel bar buckle tool 3 , a connecting rod 4 and a steel wire mesh 5 .

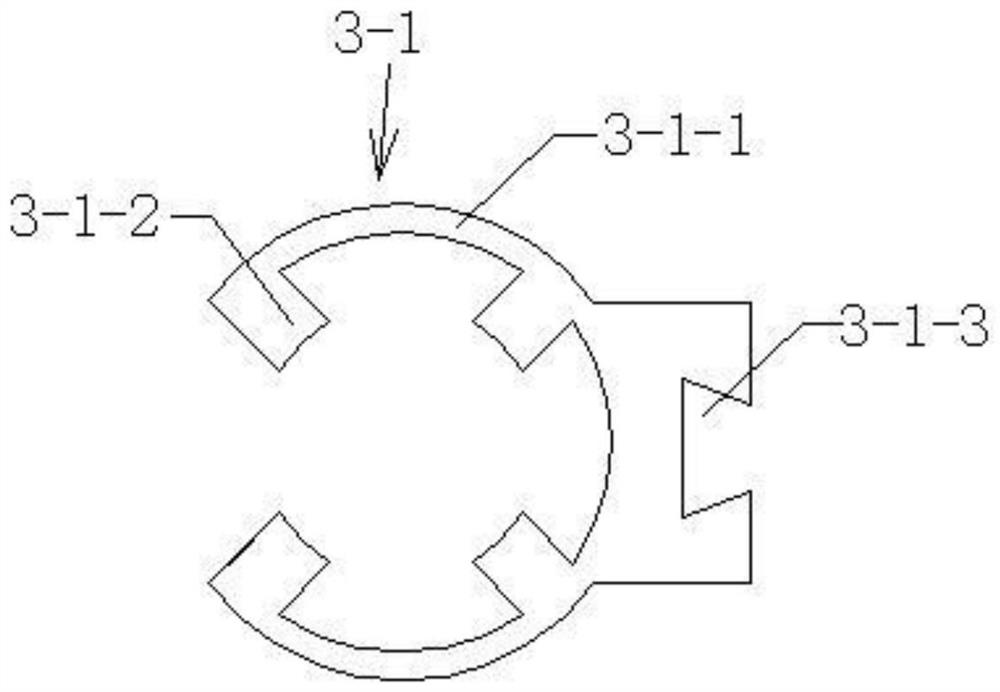

[0028] The steel buckle tool 3 includes a buckle A3-1 and a buckle B3-2, the buckle A3-1 includes a C-shaped ring-shaped buckle main body 3-1-1, and the buckle A3-1 The inner wall of the ring buckle main body 3-1-1 is provided with a plurality of inner teeth 3-1-2 integrated with it along its circumference, the inner teeth 3-1-2 are trapezoidal in design, and the inner teeth 3-1-2 The ends (one side of the trapezoidal short side) are all inclined to one side to form inverted teeth, so that when in use, the buckle can only slide to one side. A pin groove 3-1-3 is provided on the outer wall of the ring-shaped buckle main body 3-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com