Method for calculating safe drilling density of fractured formation

A drilling fluid density and formation technology, which is applied in the field of calculating safe drilling density in fractured formations, can solve problems such as the inability to consider the effects of formation wellbore stability and drilling fluid density, and incomplete drilling fluid density calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

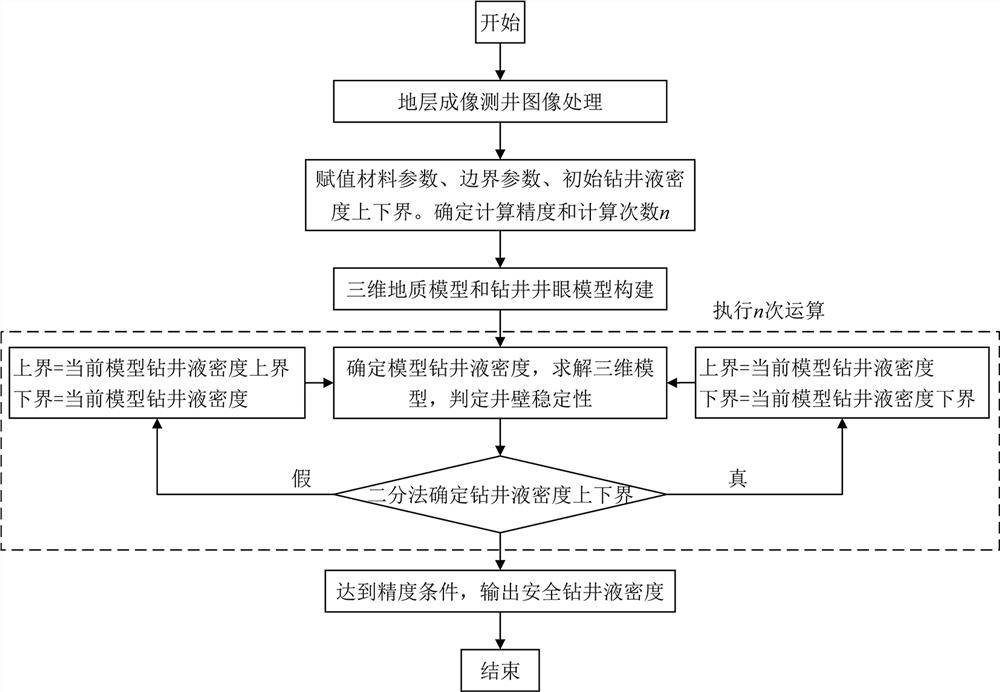

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

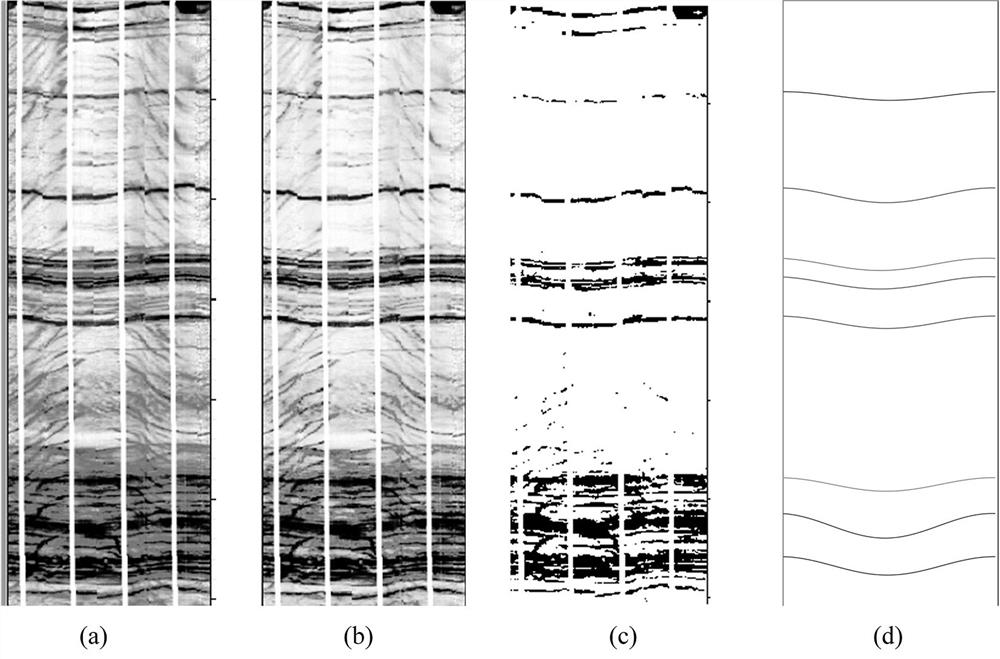

Embodiment 1

rad;

By formula and, obtain the fracture curve function of the trigonometric function curve form on wellbore, as shown in formula:

[0071]

In the formula, A, B, C are plane control parameters; z is height, and its unit is m; r is wellbore radius, and its unit is m; θ is

Well circumference angle, its unit is rad;

Known high point coordinates H (x0, y0) and low point coordinates L (x1, y1), then formula is rewritten as following formula:

[0074]

In formula, θ is well circumference angle, and its unit is rad; z is height, and its unit is m; x

0

, y

0

is the high point coordinate, x

1

, y

1

low

coordinate;

Therefore inclination angle, azimuth, inclination and curve length in fracture parameters are respectively shown as following formula:

[0077]

β=min(x

0

,x

1

) (6)

[0079]

[0080]

In formula, α is inclination angle, and its unit is rad; β is trend, and its unit is rad; λ is tendency, and its unit is rad; 1 is

The length of the curve in...

Embodiment 2

[0108]

[0110] Table 1

[0111]

[0115]

[0125]

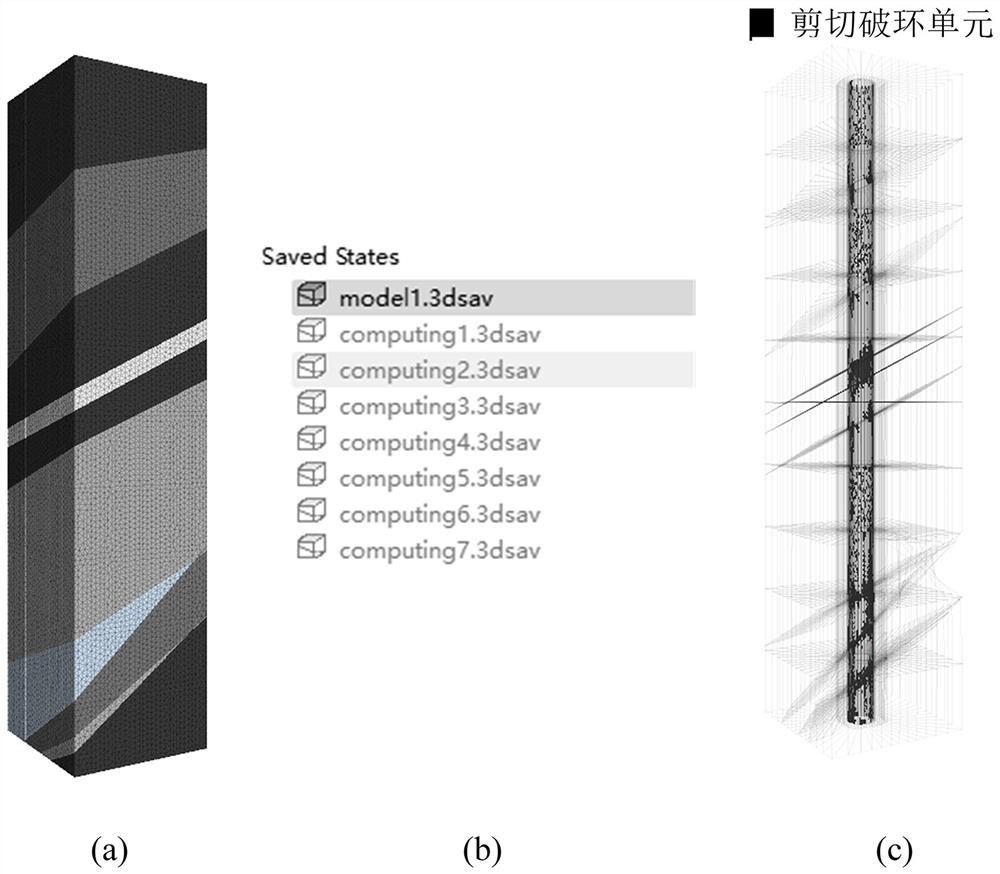

[0126] S4, utilize the discrete element method to solve the three-dimensional geological model to determine the stability of the wellbore.

[0129]

[0132]

[0133]

[0134] S6, repeat steps S4 to S5; the precision we set is 0.01, and the upper and lower limits of the drilling fluid density are 2.09 g /

[0136]

[0140] Since the formation does not have a fractured formation, the first step operation may be defaulted.

[0143]

[0153]

[0154] S4, using the discrete element method, solve the three-dimensional geological model, and determine the stability of the wellbore.

[0157]

[0160]

[0161]

[0162] S6, repeat steps S4 to S5; the precision we set is 0.01, and the upper and lower limits of the drilling fluid density are 2.09 g /

[0164]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com