Temperature-controllable thermal insulation heating device for hydrogen supply and hydrogen return of fuel cell

A fuel cell and temperature control technology, which is applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve problems such as temperature cannot be maintained, temperature cannot be monitored in real time, and temperature heating treatment is affected, so as to ensure safe temperature, The effect of avoiding heat loss and facilitating heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

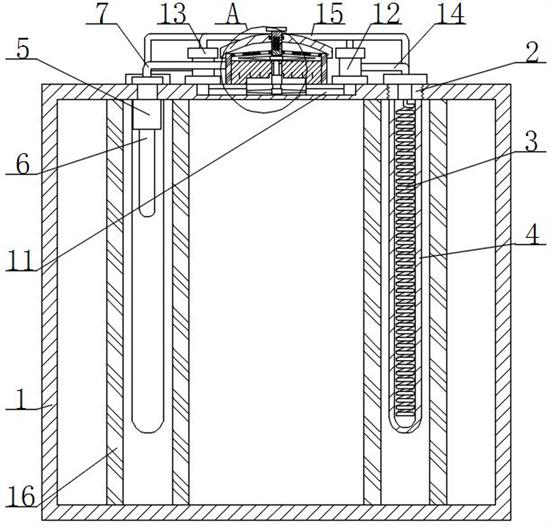

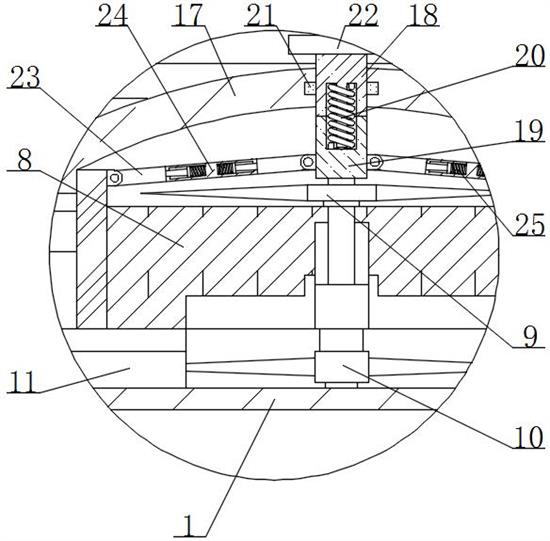

[0024] Example 1, see Figure 1-5 , the present invention provides a technical solution: a temperature-controllable fuel cell hydrogen supply and hydrogen return heat preservation heating device, comprising a battery main body 1, a positive electrode joint 12 and a negative electrode joint 13, the upper end of the battery main body 1 is screwed on the right side A threaded joint 2 is connected, a resistance wire 3 is fixedly connected to the lower end of the threaded joint 2, and a heating insulating tube 4 is arranged on the outside of the resistance wire 3, and the heating insulating tube 4 is heated by the resistance wire 3, so that the heating insulating tube 4 can be heated. The pipeline for supplying and returning hydrogen to the fuel cell can be heat-insulated and heated. A connector 5 is fixedly connected to the left side of the upper end of the battery main body 1 , and a thermometer 6 is fixedly connected to the lower end of the connector 5 , and the upper end of the ...

Embodiment 2

[0025] Example 2: see Figure 2-3 , the difference between this embodiment and Embodiment 1 is: the upper end of the thermometer 8 is fixedly connected with a watch cover 17, the middle position of the watch cover 17 is slidably connected with a torsion bar 18, and the lower end of the torsion bar 18 is rotatably connected with a lift rod 19, The surface of the rotating shaft between the lifting rod 19 and the torsion rod 18 is covered with a torsion spring 20. By rotating and pressing the torsion rod 18, the lifting rod 19 can move up and down. The temperature pointer 9 drives the connecting plate 10 to move up and down through the lifting and lowering of the lifting rod 19, which is convenient for the connection of the power supply. The surface of the torsion bar 18 is fixedly connected with a clamping block 21, and the clamping block 21 is slidably connected with the watch cover 17. After loosening, the clamping block 21 is connected with the watch cover 17, so that the tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com