Refining kettle for producing 2-ethyl anthraquinone and refining process of 2-ethyl anthraquinone

An ethyl anthraquinone and refining kettle technology, applied in the field of 2-ethyl anthraquinone preparation, can solve the problems of uneven heating, affecting the refining process, easy coking of residues, etc. The effect of prolonging the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

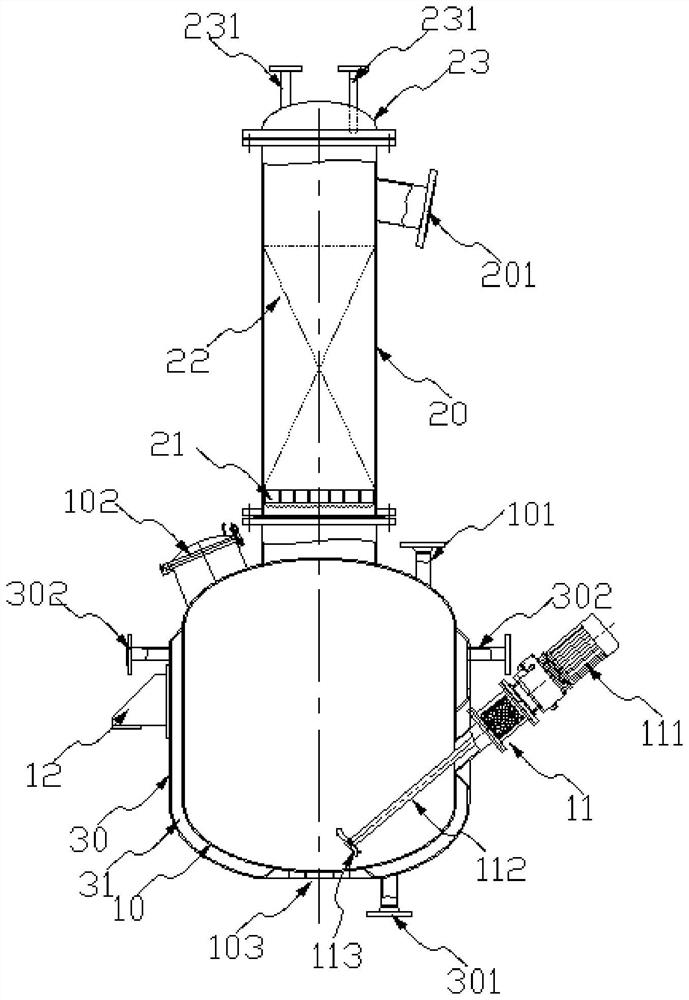

[0033] Please refer to figure 1 , the refining kettle for the production of 2-ethylanthraquinone of the present invention includes: a kettle body 10 and a tower section 20, the tower section 20 is connected to the upper end of the kettle body 10 and communicated with the kettle body 10. In the present invention, the connection between the kettle body 10 and the tower section 20 is fixed by a connecting piece (not indicated in the figure), and the connecting piece includes a connecting flange for connecting, a gasket for connecting, and a screw for connecting and fixing. Posts and Nuts. The connecting piece facilitates the installation and fixation of the kettle body 10 and the tower section 20, and is also convenient for disassembly and maintenance.

[0034] The outer wall of the kettle body 10 is provided with a jacket 30 along the body of the kettle body 10, and a filling space 31 is formed between the jacket 30 and the kettle body 10, and the filling space 31 is filled wit...

Embodiment 2

[0043] The refining process of 2-ethylanthraquinone of the present invention adopts the refining kettle for the production of 2-ethylanthraquinone of the above-mentioned embodiment 1, comprising the following steps:

[0044] Fill the filling space with heat transfer oil at a temperature of 240-260°C from the heat transfer oil inlet, discharge the heat transfer oil from the heat transfer oil outlet, preheat the kettle body, and continuously replenish heat transfer oil in circulation;

[0045] Under a vacuum environment, the 2-ethylanthraquinone crude product is dropped into the described still body from the described feeding port, starts the described stirrer, utilizes the heat that the conduction oil transmits to the 2-ethylanthraquinone in the described still body Crude products are refined;

[0046] The 2-ethylanthraquinone gas generated during the refining process is filtered through the grid plate and the wire mesh packing layer in sequence, and then discharged from the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com