Normalizing heat treatment method of nodular cast iron for automobile covering part mold

A technology for automobile cover and normalizing heat treatment, which is applied in the field of automobile cover molds, can solve the problems of low energy utilization rate, large internal stress, and large white-mouth tendency of ductile iron piston castings, so as to improve the normalizing heat treatment structure and improve the The effect of decomposition speed and improvement of normalizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

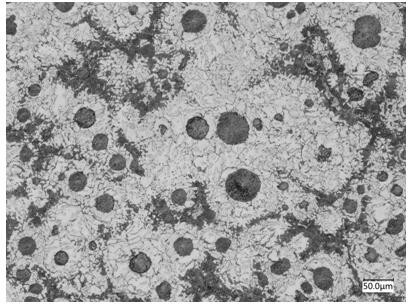

Embodiment 1

[0034] Step 1: Put the automobile panel mold sample into the heat treatment furnace, turn on the heat treatment furnace, and the heating rate is 10°C / min;

[0035] Step 2: When the temperature rises to 930°C, keep warm for 2 hours, then open the furnace door and cool with the furnace for 30 minutes;

[0036] Step 3: Then close the furnace door and raise the temperature to 720°C at 10°C / min, and keep it warm for 1 hour;

[0037] Step 4: After the heat preservation is completed, take out the automobile panel mold sample and air-cool it to room temperature under room temperature.

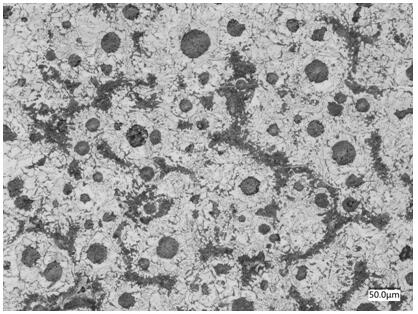

Embodiment 2

[0039] Step 1: Put the automobile panel mold sample into the heat treatment furnace, turn on the heat treatment furnace, and the heating rate is 10°C / min;

[0040] Step 2: When the temperature rises to 900°C, keep warm for 2 hours, then open the furnace door and cool with the furnace for 30 minutes;

[0041] Step 3: Then close the furnace door and raise the temperature to 720°C at 10°C / min, and keep it warm for 1 hour;

[0042] Step 4: After the heat preservation is completed, take out the automobile panel mold sample and air-cool it to room temperature under room temperature.

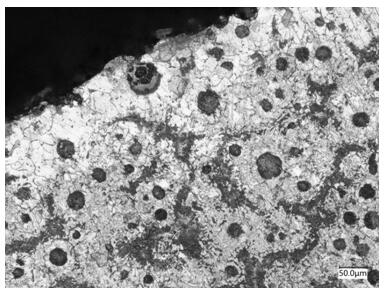

Embodiment 3

[0043] Example 3 (heating time 870°C)

[0044] Step 1: Put the automobile panel mold sample into the heat treatment furnace, turn on the heat treatment furnace, and the heating rate is 10°C / min;

[0045] Step 2: When the temperature rises to 870°C, keep warm for 2 hours, then open the furnace door and cool with the furnace for 30 minutes;

[0046] Step 3: Then close the furnace door and raise the temperature to 720°C at 10°C / min, and keep it warm for 1 hour;

[0047] Step 4: After the heat preservation is completed, take out the automobile panel mold sample and air-cool it to room temperature under room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com