Wire feeding process of anti-splashing solid calcium metal cored wire in stainless steel refining

A technology of metal calcium and cored wire, which is applied in the field of wire feeding technology, can solve the problems of unstable calcium yield, fast slag reaction burning loss, and low solubility, so as to reduce splashing, prevent molten steel from tumbling, and collect High yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further illustrated by the following examples, but is not limited to the following examples.

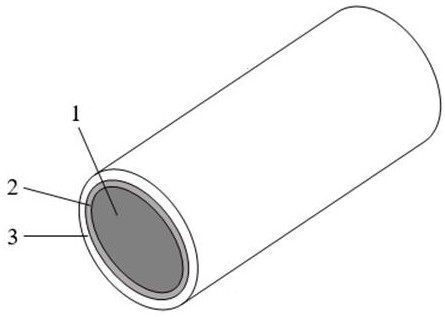

[0012] The composition and structure of the solid metal calcium cored wire used in the present invention are as follows:

[0013] The cored wire has a three-layer structure, the inner layer of calcium core is 8.0mm in diameter, and the middle layer is made of high-temperature resistant resin fiber paper to prevent the cored wire from melting fast, causing splashes on the surface of molten steel and preventing molten steel from tumbling. The outer steel strip is 0.8 mm, the material is 08 steel. Because the steel skin of the cored wire and the high-temperature-resistant resin fiber paper are completely melted after entering the molten steel, the calcium-containing vapor will not overflow in large quantities, which improves the calcium treatment effect.

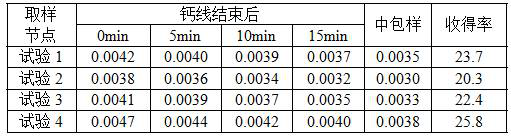

[0014] Using the above-mentioned splash-proof solid-core metal calcium cored wire, the wire feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com