Converter smelting method based on flue gas analysis

A converter smelting and flue gas analysis technology, applied in the field of iron and steel metallurgy, can solve the problems of being susceptible to external noise interference, low prediction success rate, poor equipment stability, etc. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

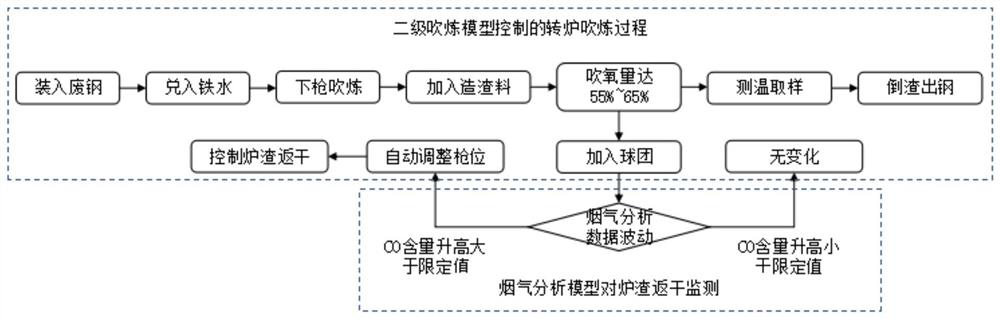

[0021] The technical method of the present invention is used to smelt in a converter with a nominal capacity of 120t. The smelting mode selects the one-button steelmaking mode. The process parameters are automatically calculated and controlled by the converter secondary blowing model, and the flue gas analysis model provides flue gas composition analysis. The data and provide the judgment result of returning dry to participate in the control of the oxygen lance position.

[0022] The secondary blowing model of the converter calculates the total amount of oxygen blowing in the main blowing stage to be 5982Nm based on data such as molten iron, scrap steel and target composition information. 3 . Oxygen blowing capacity reaches 2601Nm 3 When 60% of the total oxygen blowing volume was added, 301kg of pellets were added, and the flue gas analysis results showed that the CO content in the flue gas rose rapidly from 52% to the highest 72%, and then dropped rapidly. The CO content in...

Embodiment 2

[0025] The technical method of the present invention is used to smelt in a converter with a nominal capacity of 120t. The smelting mode selects the one-button steelmaking mode. The process parameters are automatically calculated and controlled by the converter secondary blowing model, and the flue gas analysis model provides flue gas composition analysis. The data and provide the judgment result of returning dry to participate in the control of the oxygen lance position.

[0026] The secondary blowing model of the converter calculates the total amount of oxygen blowing in the main blowing stage to be 6214Nm based on data such as molten iron, scrap steel and target composition information. 3 . Oxygen blowing capacity reaches 3728Nm 3 When 60% of the total oxygen blowing volume was added, 306 kg of pellets were added, and the flue gas analysis results showed that the CO content in the flue gas rose rapidly from 57% to the highest 68%, and then dropped rapidly. The CO content i...

Embodiment 3

[0029] The technical method of the present invention is used to smelt in a converter with a nominal capacity of 120t. The smelting mode selects the one-button steelmaking mode. The process parameters are automatically calculated and controlled by the converter secondary blowing model, and the flue gas analysis model provides flue gas composition analysis. The data and provide the judgment result of returning dry to participate in the control of the oxygen lance position.

[0030] The secondary blowing model of the converter calculates the total amount of oxygen blowing in the main blowing stage to be 6121Nm based on data such as molten iron, scrap steel and target composition information. 3 . Oxygen blowing capacity reaches 3673Nm 3 When 296kg of pellets were added, the CO content in the flue gas rose rapidly from 47% to the highest 74% and then dropped rapidly. The CO content increased by 27%, and the flue gas analysis model judged that the slag was dry, and the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com