Cooler

A cooler and cooling core technology, applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of internal flow channel leakage, large footprint, and affecting the heat exchange efficiency of coolers, etc., to achieve The effect of reducing heat exchange speed and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

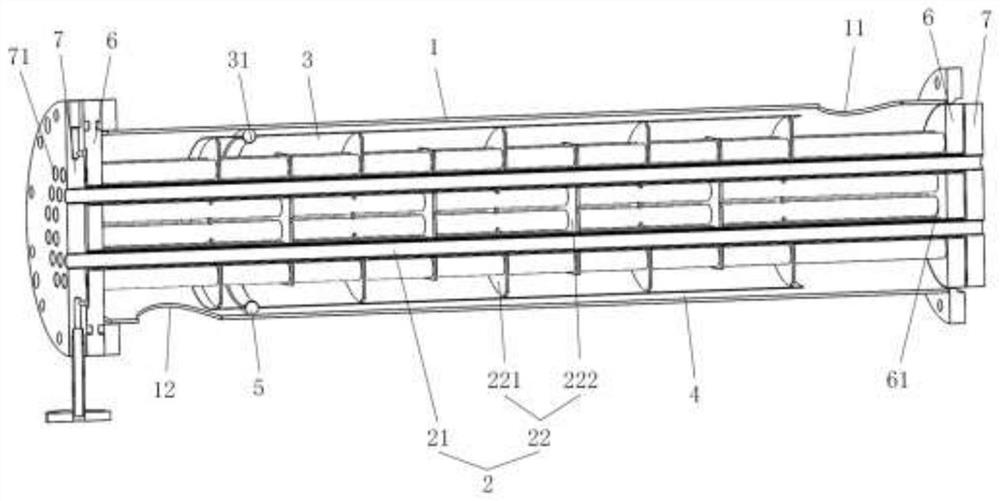

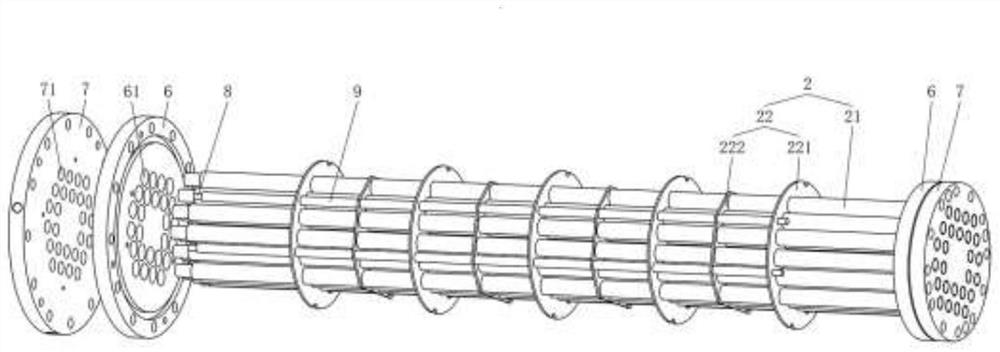

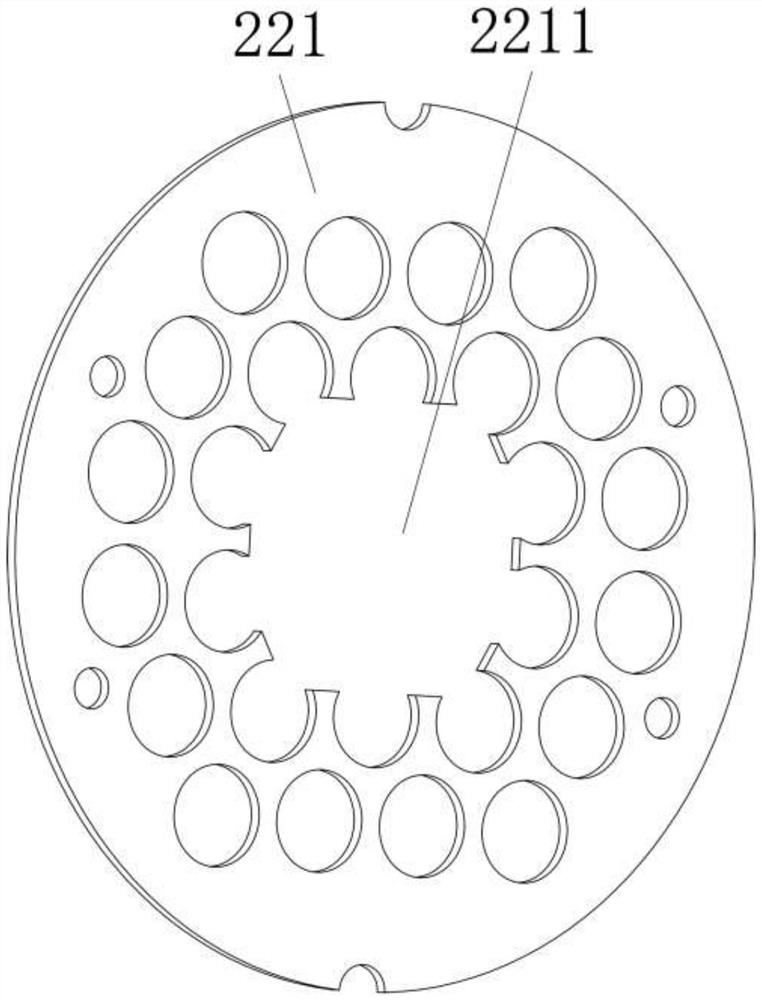

[0039] like figure 1 , figure 2 , a cooler, including a cylindrical shell 1, a cooling core group 2 and an inner tank 3 installed through the shell 1; the two ends of the shell 1 are respectively provided with an oil inlet 11 and an oil outlet 12; the cooling core group 2 It includes a flow pipe 21 and a guide plate 22 , and the flow pipe 21 and the guide plate 22 are installed inside the inner tank 3 ; an oil storage cavity 4 is formed between the outer wall of the inner tank 3 and the shell 1 .

[0040] Therefore, installing the inner tank 3 between the deflector 22 and the casing 1 can form a seal at the edge of the deflector 22 to ensure that the oil is cooled through the through-flow pipe 21 and improve the heat exchange efficiency; the oil storage cavity 4. The inner oil flows in, and an oil layer that does not participate in the cooling cycle is formed between the inner tank 3 and the shell 1, which can play a certain role of heat insulation, reduce the heat exchange ...

Embodiment 2

[0054] like figure 1 The outer wall of the inner tank 3 is provided with a sealing member installation groove 31 , and a sealing member 5 is installed in the sealing member installation groove 31 .

[0055] Therefore, the seal 5 generally adopts an O-ring to ensure that the oil will not leak from the seal.

[0056] like figure 1 , the seal installation groove 31 is located at one end of the outer wall of the inner tank 3 close to the oil outlet 12 .

[0057] In this way, the oil storage cavity 4 covers the entire cooling core group 2 to ensure the thermal insulation performance of the cooling core group 2 , thereby improving the heat exchange efficiency of the cooler.

[0058] like figure 1 , the thickness of the oil storage cavity 4 is 0.8mm-2mm.

[0059] Therefore, the insufficient thickness of the oil storage cavity 4 will affect the thermal insulation performance, and if the thickness is too large, the volume of the cooler will be increased. Controlling its thickness t...

Embodiment 3

[0061] like figure 1 , figure 2 , the cooler also includes an inner pipe cover plate 6, which is installed at both ends of the casing 1 and forms a seal with the casing 1; the inner pipe cover plate 6 is provided with an inner pipe installation hole 61, and the flow through Both ends of the tube 21 are inserted into the inner tube mounting holes 61 for installation.

[0062] Therefore, the inner pipeline cover plate 6 is used to seal both ends of the casing 1, and provides a cooling liquid interface for the through-flow pipe 21, which can make the structure of the cooler more compact and the installation more convenient.

[0063] like figure 1 , figure 2 , the cooler also includes an outer pipeline cover plate 7, the outer pipeline cover plate 7 is installed on the outside of the inner pipeline cover plate 6 and is flanged to the inner pipeline cover plate 6; the outer pipeline cover plate 7 is provided with The outer pipe installation hole 71 is inserted into the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com