Method for loading cracks of prefabricated mortar test piece through three-point bending

A technology of three-point bending and mortar, which is applied in the field of hydraulic concrete material testing, can solve problems such as fixity and single crack shape, and achieve the effects of cost saving, single crack shape and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

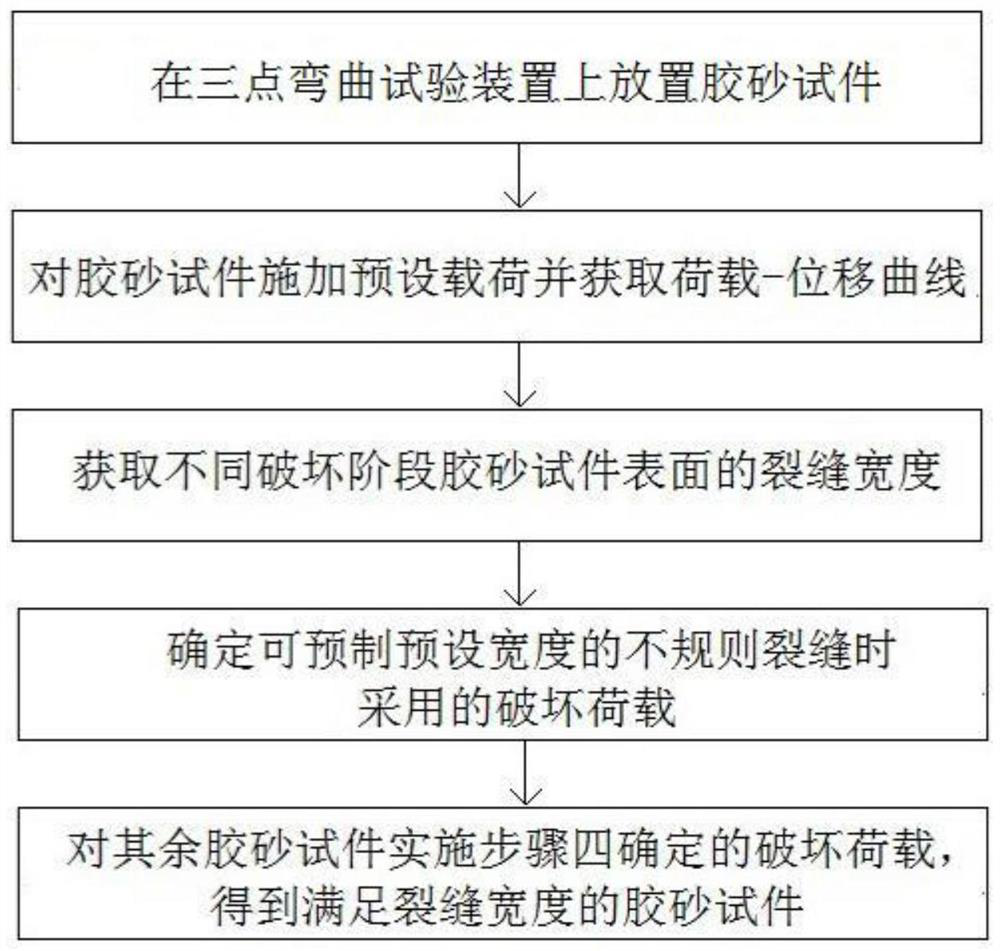

[0037] refer to figure 1 and figure 2 A method for loading cracks in prefabricated mortar specimens using three-point bending is shown, including the following steps

[0038] Step 1: Place the mortar specimen 1 on the three-point bending test device;

[0039] Place one of the pre-prepared multiple mortar specimens 1 on the three-point bending test device;

[0040] Step 2: Apply a preset load to the mortar specimen 1 through a three-point bending test device and obtain a load-displacement curve;

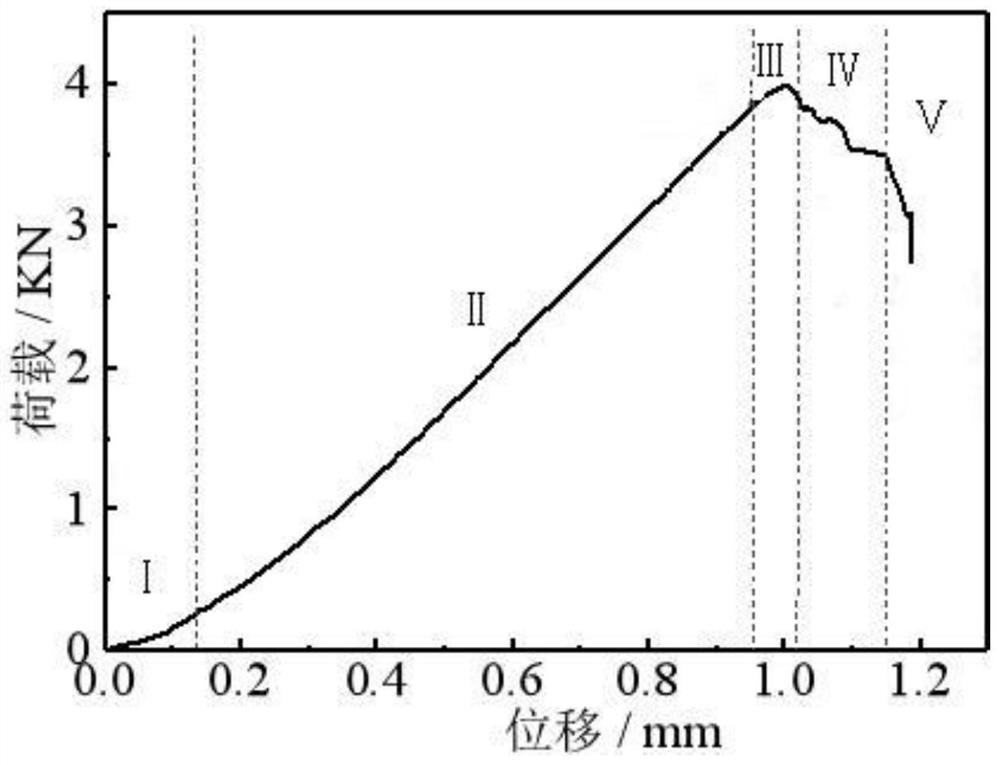

[0041] Step 3: analyze the failure form and load-displacement curve characteristics of the prefabricated mortar specimen 1, and obtain the crack width on the surface of the mortar specimen 1 in different failure stages;

[0042] Step 4: Determine the failure load used when irregular cracks with preset widths can be prefabricated;

[0043] Step 5: Apply the failure load determined in Step 4 to the rest of the mortar specimens, and obtain the mortar specimen 1 that meets the width ...

Embodiment 2

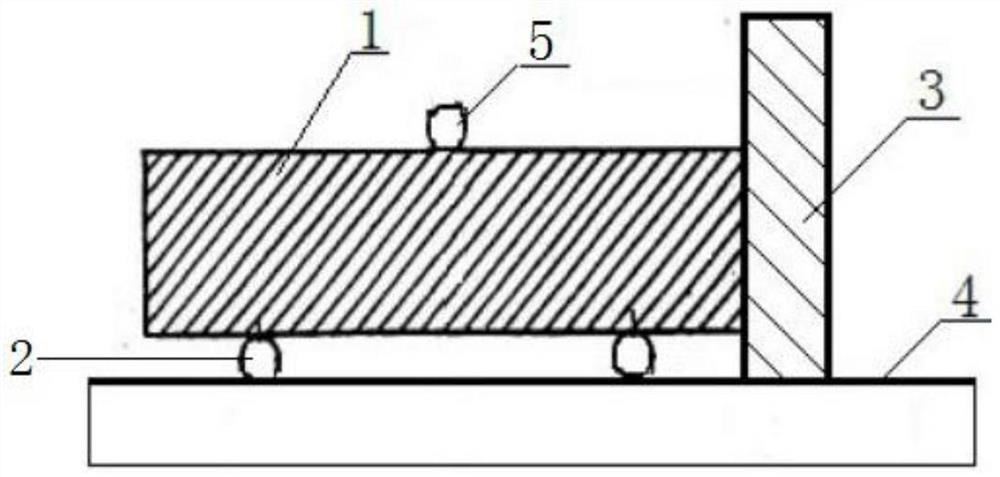

[0051] refer to figure 1 and figure 2 A method for loading cracks in prefabricated mortar specimens by three-point bending is shown. On the basis of Embodiment 1, the three-point bending test device used in the first step is a computer-controlled compression and bending integrated machine. The computer-controlled compressive and anti-folding integrated machine includes at least one loading cylinder 5, two supporting cylinders 2, a force loading part and a computer; the force loading part is used to apply a load force to the sand sample 1 ; Described computer is connected with force loading part by electrical signal; Described two supporting cylinders 2 are fixed on the hydraulic platform 4 of the computer-controlled anti-compression and anti-folding machine; The upper part of described loading cylinder 5 is fixedly connected to the force loading part, and is located above the middle of the two supporting columns 2.

[0052] In actual use, the mortar specimen 1 is first plac...

Embodiment 3

[0056] refer to figure 1 and figure 2 A method of loading prefabricated mortar specimen cracks by three-point bending is shown, on the basis of the second embodiment, the two supporting cylinders 2 are fixed on the hydraulic platform 4 in parallel, and the loading cylinder 5 and the two supporting cylinders are fixed on the hydraulic platform 4 in parallel. The support cylinder 2 is parallel, and the axial directions of the support cylinder 2 and the loading cylinder 5 are both perpendicular to the long axis direction of the mortar specimen 1 .

[0057] The adoption of this technical solution makes it comply with the relevant regulations in Section 4 of GB / T 17671, so as to prepare a mortar specimen 1 that meets the preset crack width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com