Preparation method of pellet ore and binder and pellet ore prepared by using preparation method of pellet ore and binder

A technology of pellets and binders, applied in the direction of improving process efficiency, etc., can solve the problem of high cost of pellets, and achieve the effects of saving inventory management costs, ensuring strength, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention relates to a method for preparing pellets and a binder which can reduce the cost for preparing pellets and can reuse the slag produced in the ferronickel preparation process. More specifically, the present invention relates to a method for preparing pellets and a binder, which can ensure the strength and reduce the preparation cost when preparing the pellets used as raw materials in the preparation of ferronickel.

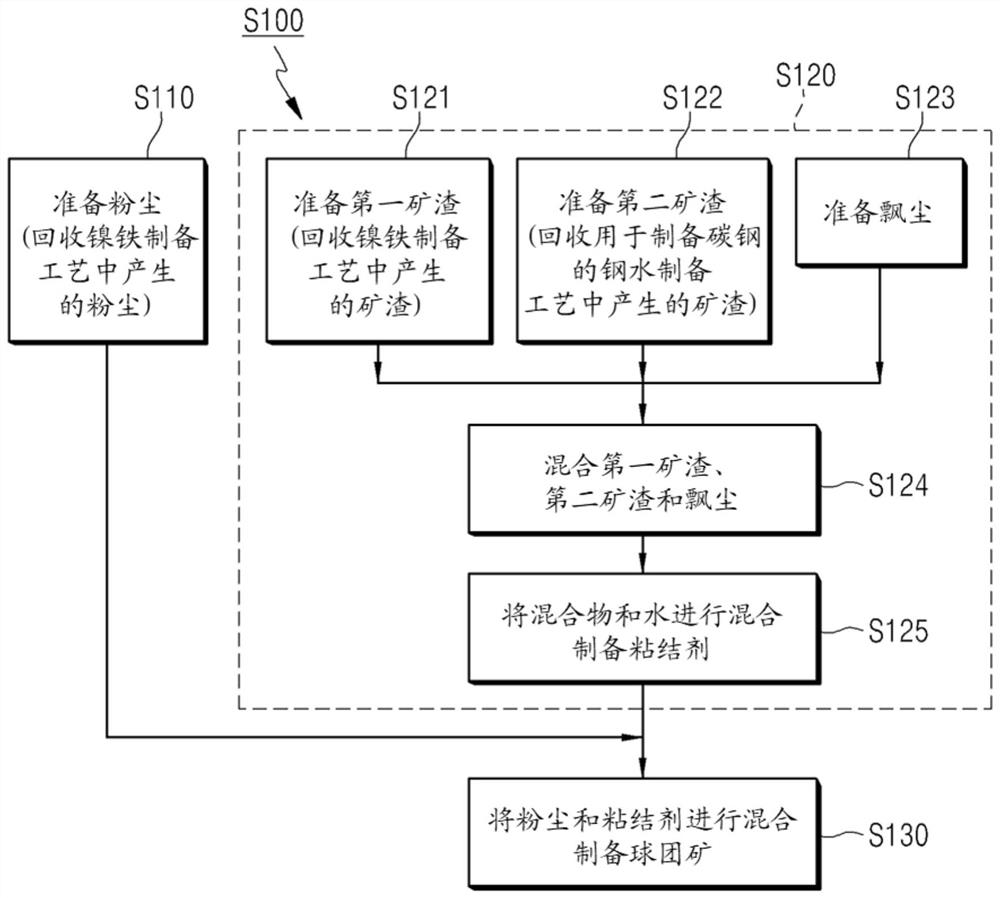

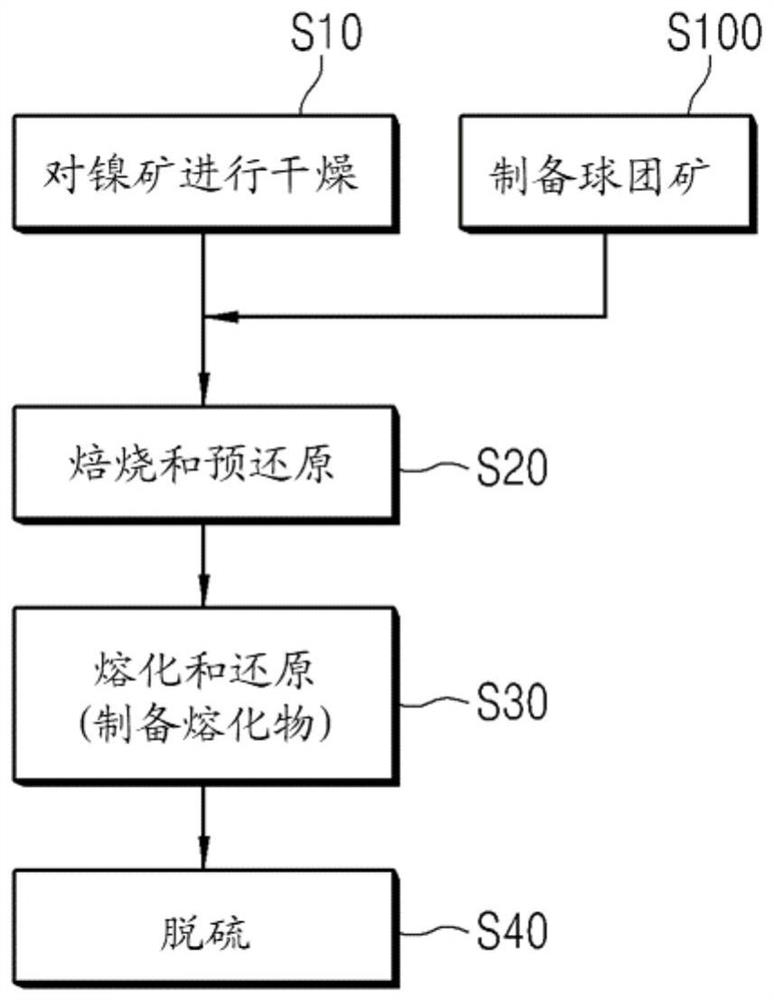

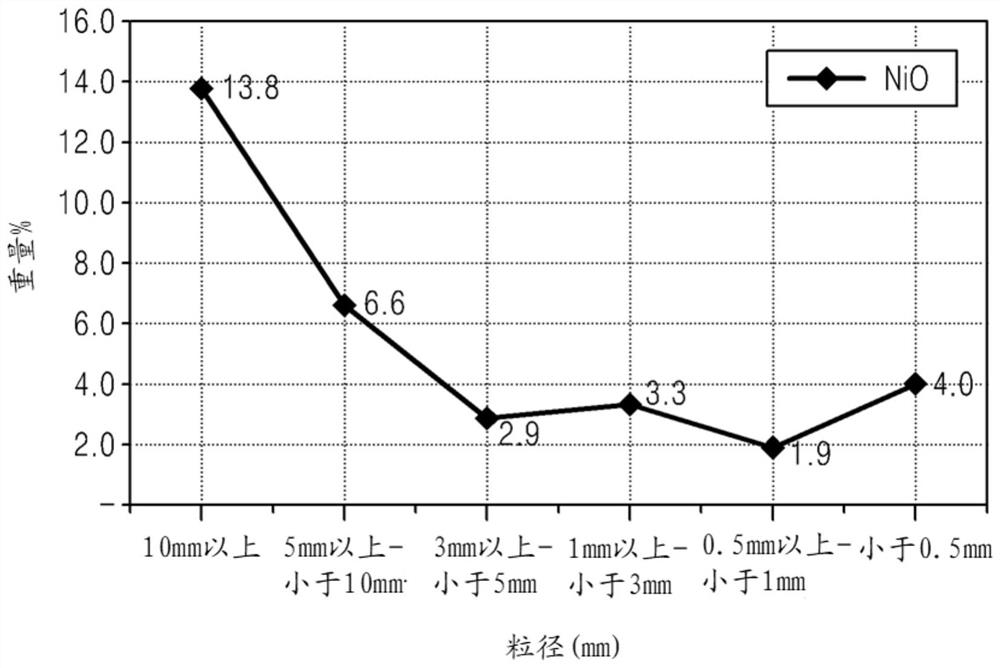

[0052] figure 1 It is a flow chart showing sequentially the method for preparing pellets according to the first embodiment of the present invention. figure 2 are views sequentially showing a conventional nickel-iron production method. image 3 is a graph showing the content of nickel oxide (NiO) based on the particle size of slag, which is the slag produced by the desulfurization process in the production process of ferronickel.

[0053] see figure 1 , the method S100 for preparing pellets according to the first embodiment of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com