Supported platinum-based catalyst as well as preparation and application thereof

A catalyst, supported technology, applied in the field of nanomaterials, can solve the problems of reduced MOR, EOR or ORR activity, increased catalyst preparation time and cost, electrocatalyst cost and technical difficulties, etc., to avoid formation, agglomeration, and production costs. Low, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

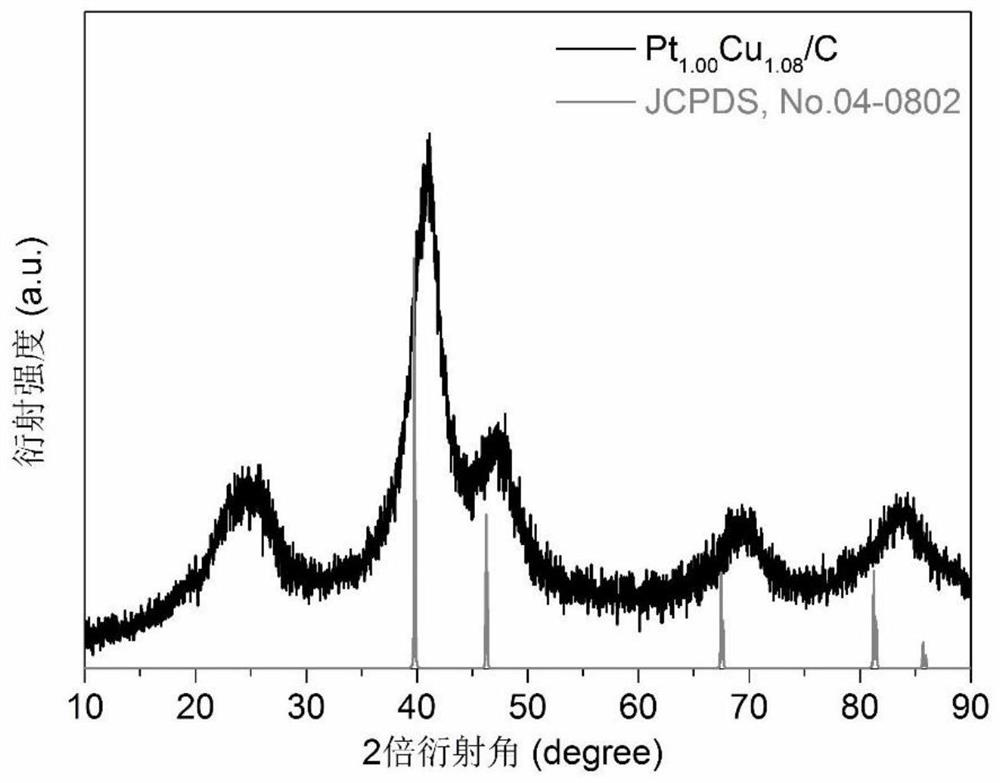

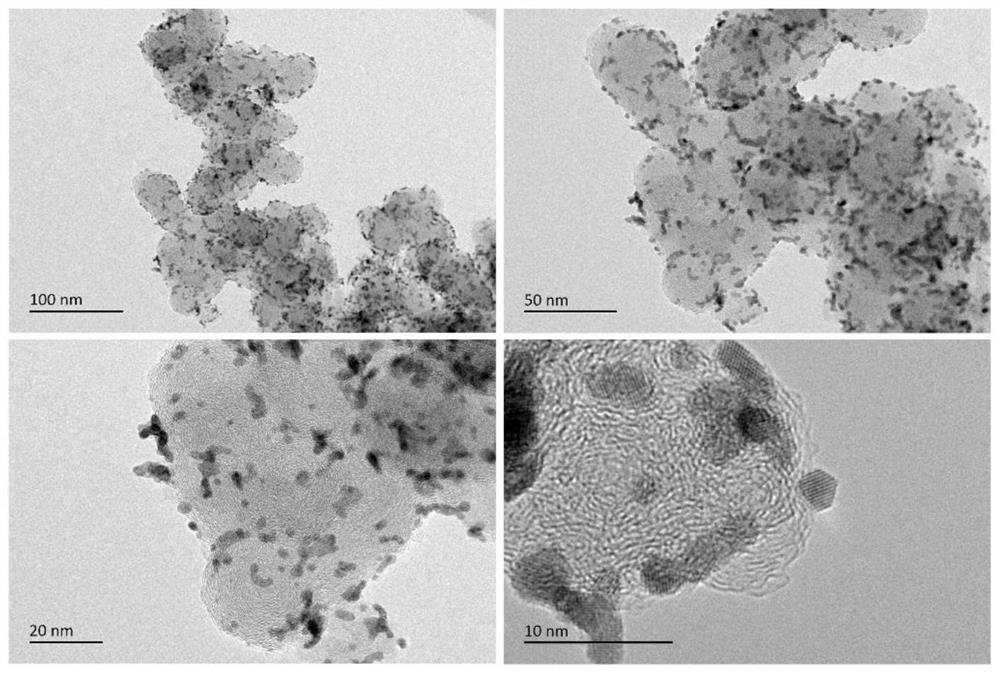

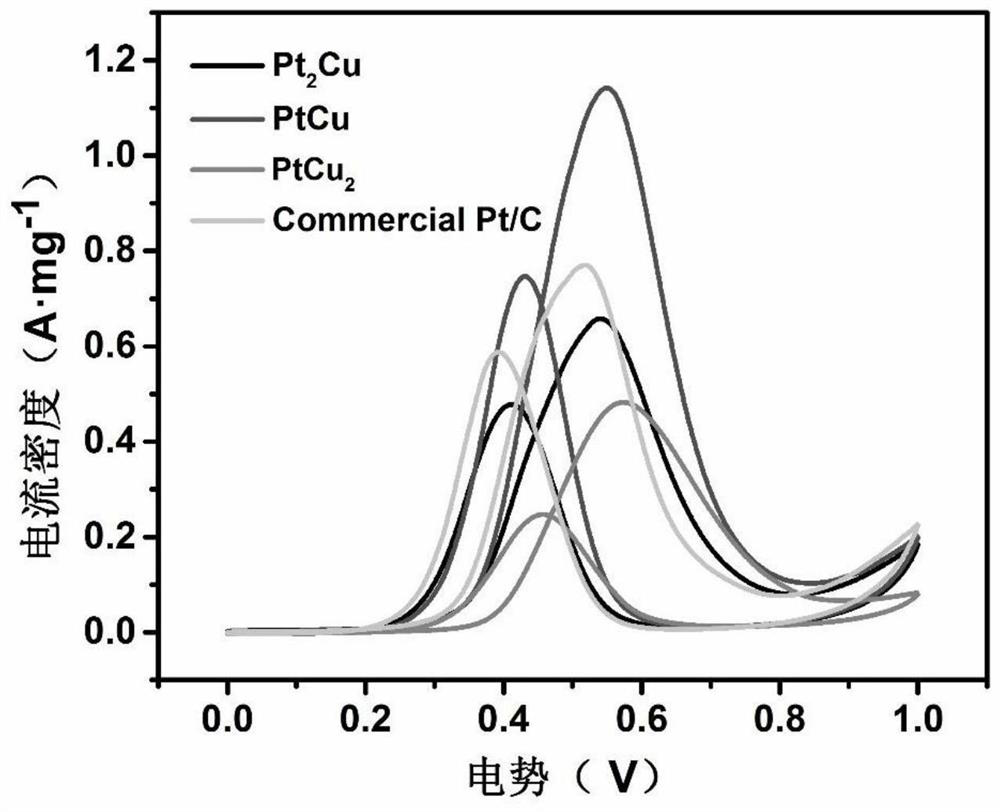

[0033] Example 1 PtCu / C nanocatalyst

[0034] Weigh 40 mg of XC-72 carbon carrier, disperse it in a 200 mL beaker containing 50 mL of ethanol, ultrasonicate for 30 minutes, and stir for 30 minutes to fully disperse the carbon carrier to form a slurry. Pipette 1.67mL of H 2 PtCl 6 ·6H 2 O ethanol solution (6 mg / mL) and 15 mL of Cu(acac) 3 Ethanol solution (0.05 mM) was successively added to a 200 mL beaker filled with carbon slurry, stirred at a stirring rate of 600 rpm for 1 h, and then sonicated for 3 hours. After the metal salt was uniformly impregnated, 20 mL of sodium borohydride ethanol solution (0.1 mmol / mL) was added to the above system at a drop rate of 0.2 mL / min. The reaction was stopped after 2 hours of reaction. The reacted mixture was transferred to a centrifuge test tube, centrifuged to obtain a solid product, washed twice with water and ethanol, and dried in a vacuum oven at 80°C for 18 hours to obtain a PtCu / C nanocatalyst. Thermogravimetric analysis show...

Embodiment 2

[0036] Example 2 Pt 10 Cu / C nanocatalyst

[0037] The operation process and conditions are the same as in Example 1. The difference between this example and Example 1 is that the amount of Cu precursor is changed, and the molar ratio of Pt and Cu in this example is 10:1. The Pt 10 Cu / C catalysts have catalytic activity for MOR.

Embodiment 3

[0038] Example 3 Pt 5 Cu / C nanocatalyst

[0039] The operation process and conditions are the same as in Example 1. The difference between this example and Example 1 is that the amount of Cu precursor is changed, and the molar ratio of Pt and Cu in this example is 5:1. The Pt 5 Cu / C catalyst has catalytic activity for MOR

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap