A high-efficiency spray device

An injection device and high-efficiency technology, which can be used in injection devices, liquid injection devices, etc., can solve the problems of loss of heat energy, waste of energy, inability to withstand high temperature of steam, etc., and achieve the effect of avoiding losses and ingenious ideas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

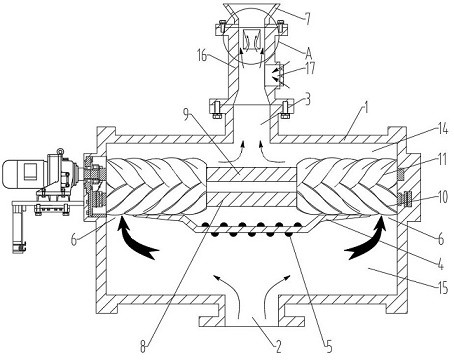

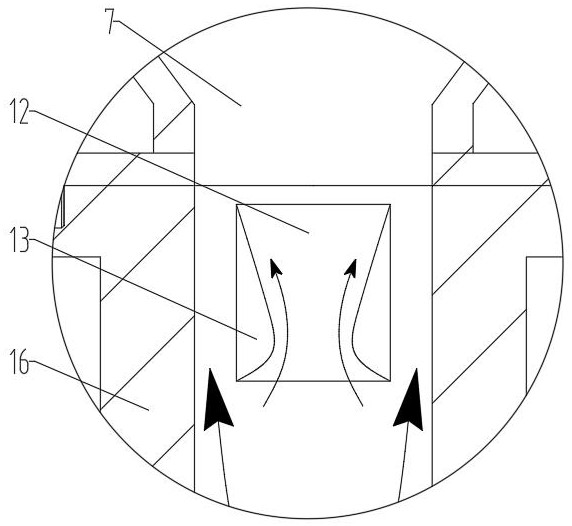

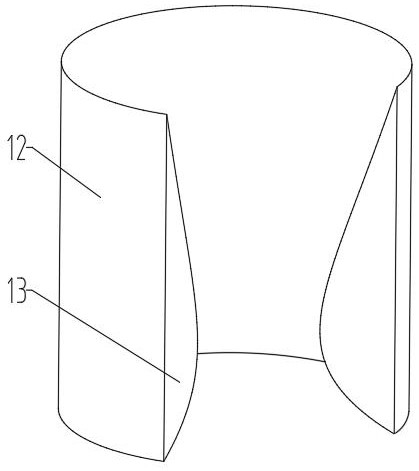

[0025] Example: as Figure 1-3 As shown, a high-efficiency spray device includes a closed water storage bin 1 provided with a water inlet 2 and a water outlet 3, the water storage bin 1 is provided with a water baffle 4 inside and a heating assembly 5 is arranged on the water baffle 4 ; The left and right sides of the water baffle 4 and the inner wall of the water storage bin 1 are provided with a water flow channel 6; the water storage bin 1 is located at a position above the water flow channel 6. A pressurized assembly is provided; the water outlet 3 is installed There is a spray head 7, and a pressurized plate is installed inside the spray head 7; the pressurization assembly includes a female rotor 8 and a male rotor 9 that are horizontally installed in the water storage bin 1 and located above the water flow channel 6, and the left and right sides of the female rotor 8. Both ends are symmetrically provided with a first threaded portion 10, and the left and right ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com