Universal multi-angle curtain wall connecting mechanism

A connection mechanism and multi-angle technology, applied in the direction of walls, building components, building structures, etc., can solve the problem of not being able to adapt to the richness of building facades, the high cost of materials and arc processing, and the inability to meet the development needs of building curtain walls, etc. Problems, to achieve simple and beautiful indoor effect, saving labor costs for processing and installation, and simple and fast processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

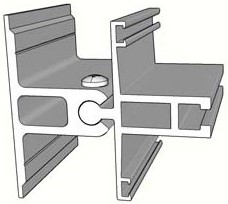

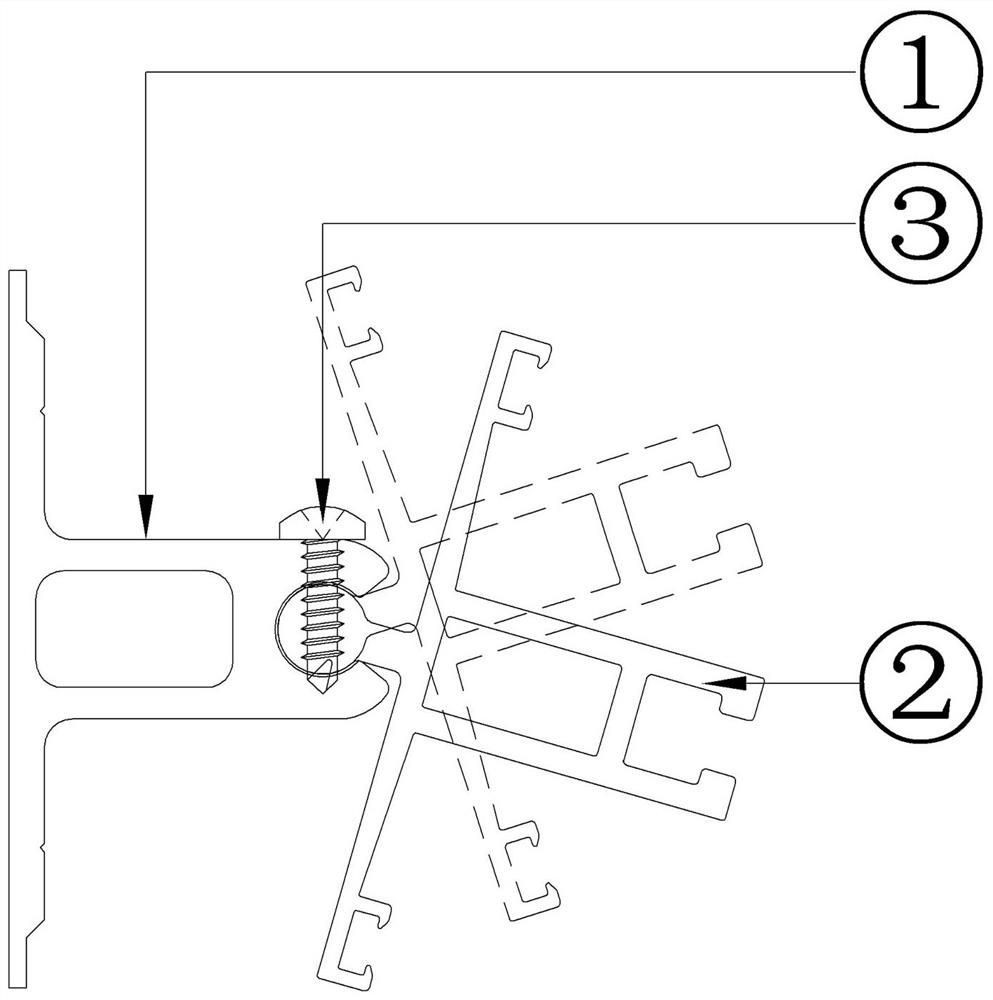

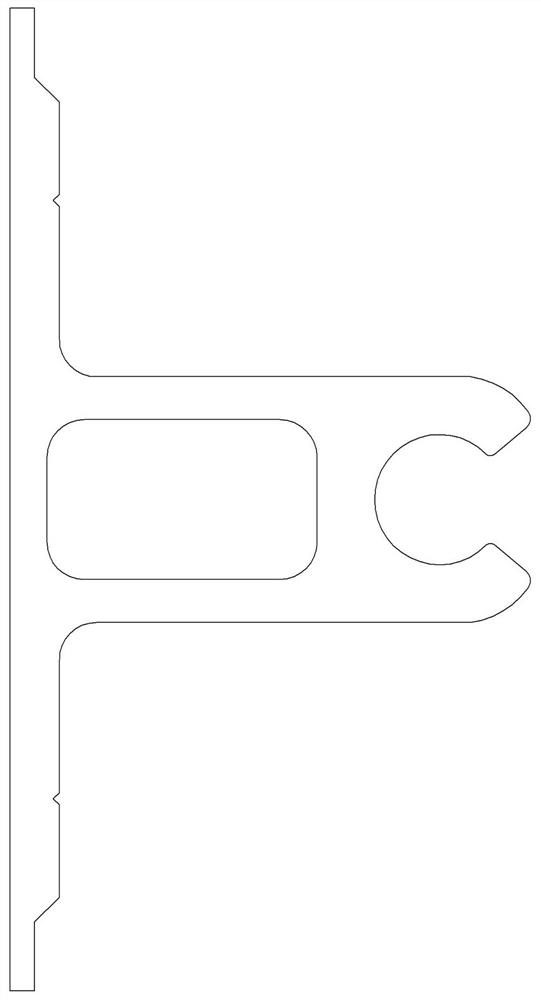

[0023] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the fixed base 1 and the steering base 2 are cut and processed in the factory, the sealing rubber strip 6 is inserted into the rubber strip groove of the steering base 2, and the circular steering shaft of the steering base 2 is inserted into the circular groove of the fixed base 1. The outstretched wings on both sides of the bottom plate of the fixed base 1 are installed on the curtain wall keel 5 through stainless steel machine screws 4 . Then insert the circular steering shaft on the steering seat 2 into the circular notch of the fixed base 1. After rotating the steering seat 2 to the required angle, use stainless steel screws 3 to connect the connection between the fixed base 1 and the steering seat 2. The curtain wall The panel 8 is installed between two adjacent steering seats 2 , and the outer curtain wall pressing plate 9 presses the curtain wall panel 8 through stainless steel bolts 7 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com