High-lift-drag-ratio wind turbine airfoil profile under large attack angle and design method of high-lift-drag-ratio wind turbine airfoil profile

A technology with high lift-to-drag ratio and design method, which is applied to wind turbines, wind turbines, mechanical equipment and other directions that are consistent with the wind direction, can solve the problem of low aerodynamic efficiency of vertical axis wind turbines, reduce the economic benefits of wind turbine rotors, and is easy to appear. Airflow separation and other issues, to achieve the effect of improving wind energy absorption efficiency, small resistance and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

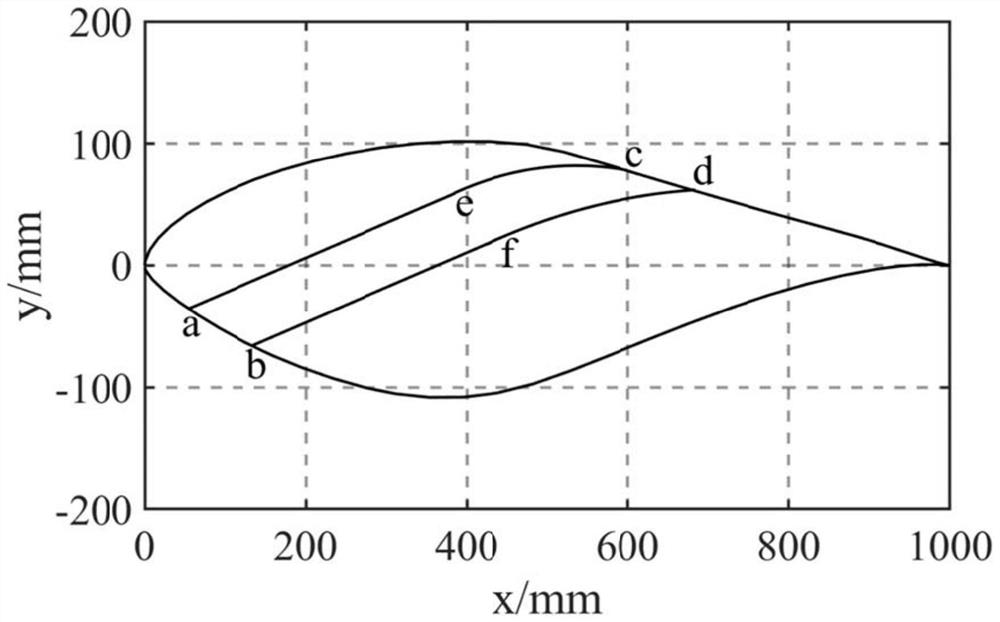

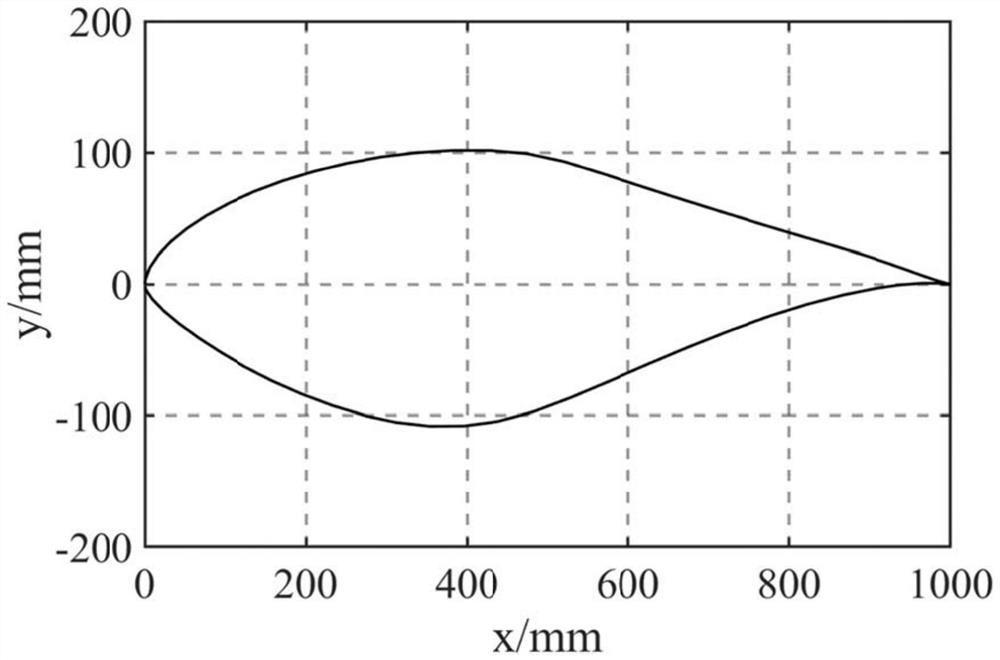

[0050] In the high lift-to-drag ratio wind wing model provided by the present invention, the front section of the slit is linear, and the rear section is circular. ae and bf are two line segments, ec and fd are two arcs, and the chord length of the reference airfoil profile is C, where a x =0.05C, b x =0.13C, c x =0.59c,d x =0.66C, the width of ab is 0.08C, ae is parallel to bf, the lateral distance of ae is 0.34C, bf=0.32C, the angle between ae and the x-axis is 16°, ec is an arc with a radius of 0.52Cmm, and Tangent to the upper airfoil, and fd is an arc with a radius of 0.41C and a cd width of 0.07C. It is named S809-1 after this.

Embodiment 2

[0052] In the high lift-to-drag ratio wind wing model provided by the present invention, the front section of the slit is linear, and the rear section is circular. ae and bf are two line segments, ec and fd are two arcs, and the chord length of the reference airfoil profile is C, where a x =0.05C, b x =0.12C, c x =0.55C, d x =0.63C, the width of ab is 0.07C, ae is parallel to bf, the lateral distance of ae is 0.34C, bf=0.32C, the angle between ae and the x-axis is 10°, ec is an arc with a radius of 0.51Cmm, and Tangent to the upper airfoil, fd is an arc with a radius of 0.41C, and the width of cd is 0.07C, denoted as S809-4.

Embodiment 3

[0054] In the high lift-to-drag ratio wind wing model provided by the present invention, the front section of the slit is linear, and the rear section is circular. ae and bf are two line segments, ec and fd are two arcs, and the chord length of the reference airfoil profile is C, where a x =0.08C, b x =0.18C, c x =0.65C, d x =0.75C, the width of ab is 0.1C, ae is parallel to bf, the lateral distance of ae is 0.34C, bf=0.32C, the angle between ae and the x-axis is 20°, ec is an arc with a radius of 0.53Cmm, and Tangent to the upper airfoil, fd is an arc with a radius of 0.42C, and the width of cd is 0.1C, denoted as S809-5.

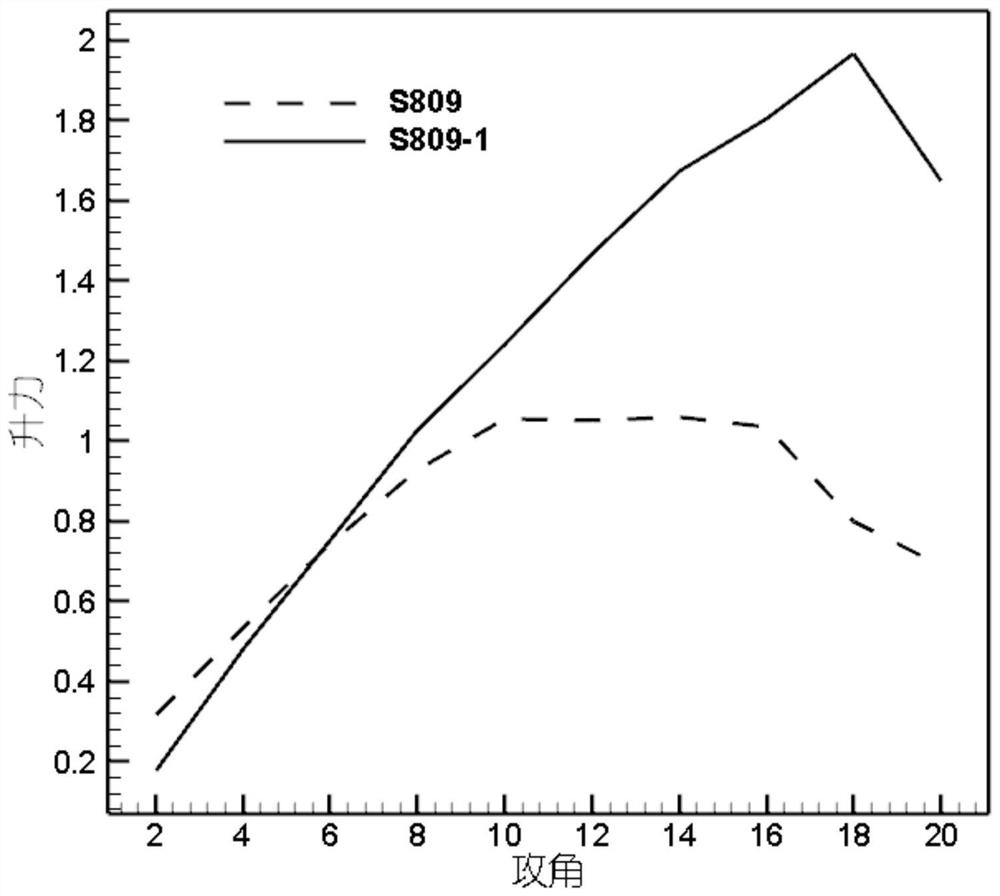

[0055] from Figure 14 It can be seen that compared with the reference airfoil, the slotted airfoil will have a better lift-drag ratio, but the position and shape of the slot are the key.

[0056] The advantages of a wind turbine airfoil with a high lift-to-drag ratio of the present invention are verified by comparing the following different inflow an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com