Non-metal carbon fiber full-winding high-pressure hydrogen storage bottle inner container bottle opening structure

A carbon fiber, non-metallic technology, applied in the field of non-metallic carbon fiber fully wound high-pressure hydrogen storage bottle liner bottle mouth structure, can solve the problems of inconvenient sealing performance, inconvenient and stable clamping installation, etc., to avoid unstable and stable fixation Simple installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

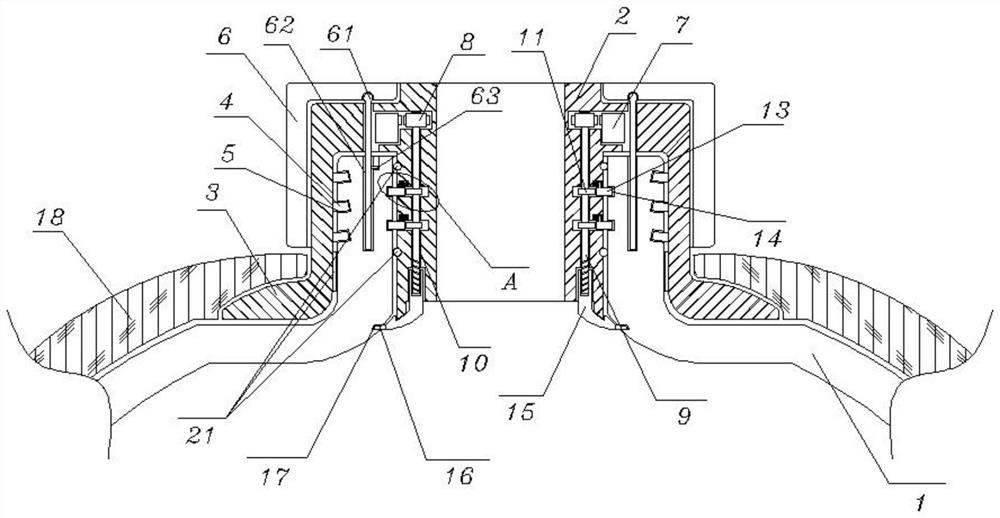

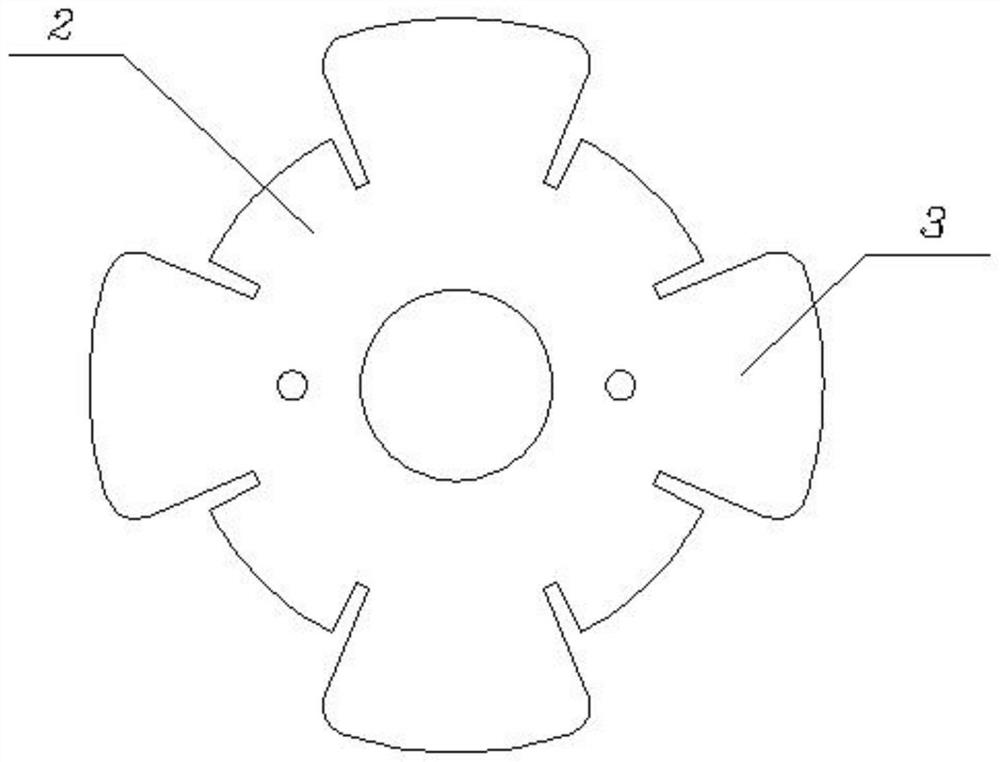

[0033] see Figure 1-6, including a plastic bottle mouth 1, the end of the plastic bottle mouth 1 is sleeved with a metal kit 2, and the outer side of the metal kit 2 is connected with a raised edge 3, and the raised edge 3 is located outside the top of the plastic bottle mouth 1, The contact positions of the metal sleeve 2 and the raised edge strip 3 and the plastic bottle mouth 1 are all provided with a sealing gasket 21, and the plastic bottle opening 1 and the metal sleeve 2 and the raised edge strip 3 are all wound with a carbon fiber winding layer 18; also includes : the fixing sleeve 6, the fixing sleeve 6 is threadedly sleeved on the outer side of the top of the metal sleeve 2, and the initial position of the fixing sleeve 6 is located above the raised edge strip 3, and the inner wall of the raised edge strip 3 is fixed with an outer fixing strip 4, and The outer fixing strip 4 is located in the outer fixing groove 5, and the outer fixing groove 5 is opened on the oute...

Embodiment 2

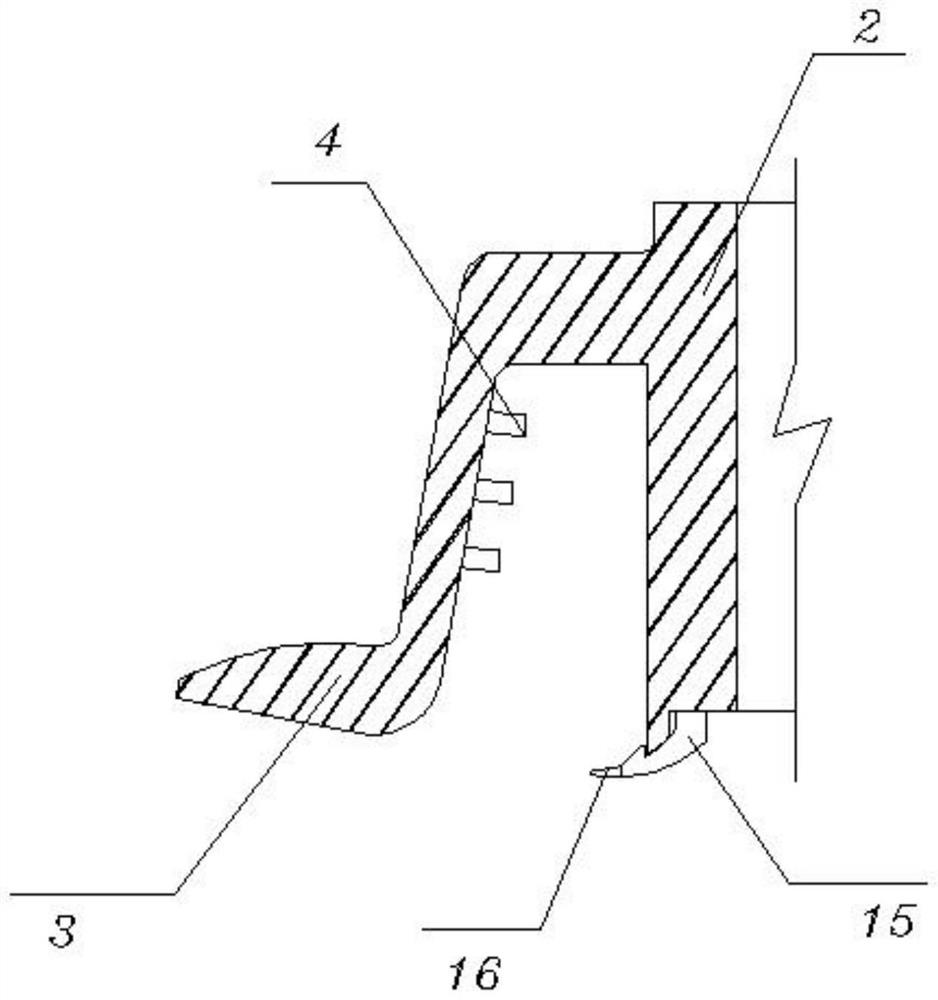

[0035] see figure 1 and Figure 4-7 , the sealing cover 15, the sealing cover 15 is threadedly sleeved at the bottom position of the vertical rod 9, and the bottom end of the sealing cover 15 is located below the metal sleeve 2, the bottom edge of the sealing cover 15 is fixed with a positioning convex strip 16, and the positioning convex One end of the strip 16 is located in the locking groove 17, and the locking groove 17 is opened on the inner wall of the arc section below the plastic bottle mouth 1, the sealing cover 15 is vertically fit and slides in the vertical groove 10 through the vertical rod 9, and the sealing cover 15 The bottom of the metal sleeve 2 has a horn-shaped structure, which is matched with the bottom of the metal sleeve 2 and the arc end of the inner wall of the plastic bottle mouth 1, and the bottom edge of the metal sleeve 2 has a convex structure design. , and the concave-convex match between the positioning convex strip 16 and the locking groove 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com