Display glass preparation device with adjustable reflectivity in frame area

A technology for preparing device and reflectivity, which is applied to computer monitor casings, instruments, computing, etc., can solve problems such as poor reflectivity of protective glass, and achieve the effect of avoiding local lighting, improving flatness, and ensuring completion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

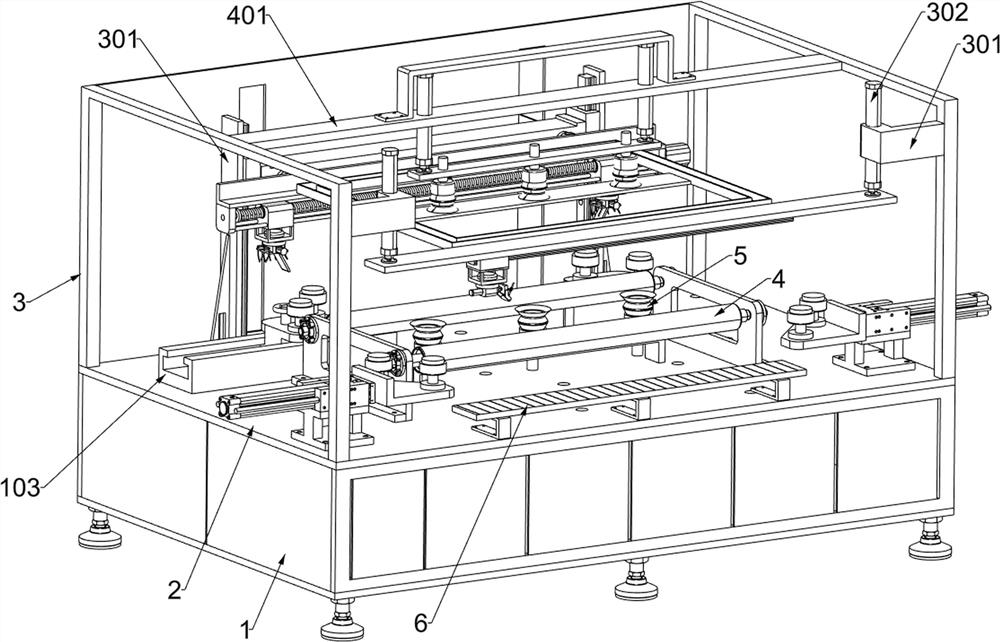

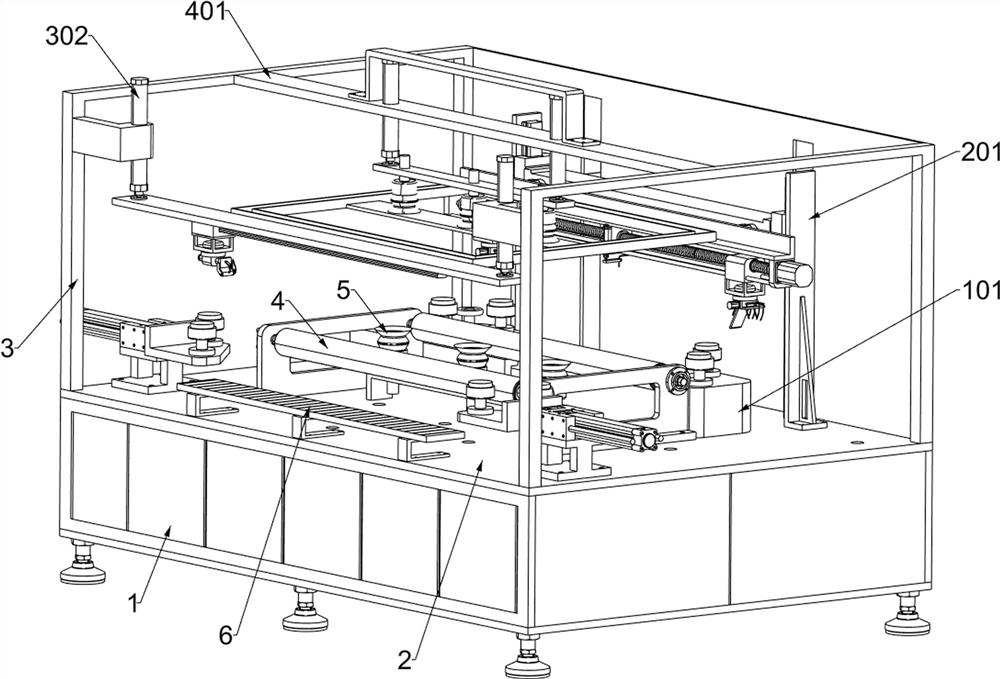

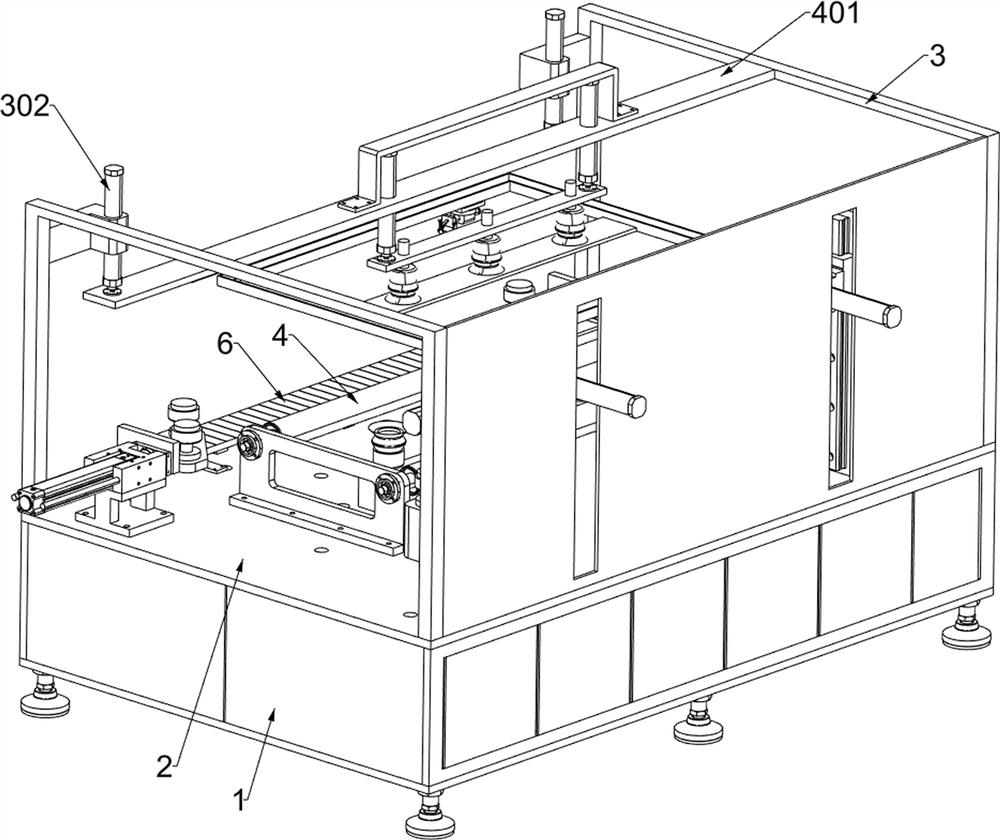

[0033] A display glass preparation device with adjustable bezel area reflectivity, such as figure 1 , figure 2 and image 3 As shown, it includes a frame 1, a workbench 2, a fixed frame 3, a guide roller assembly 4, a linear illumination lamp group 6, a positioning system, a push printing system and a repair system; the upper surface of the frame 1 is fixed with a workbench 2 ; The left part of the upper surface of the worktable 2 and the right part of the upper surface are each fixed with a fixed frame 3; the middle part of the upper surface of the worktable 2 is fixed with a guide roller assembly 4; Group 6; a positioning system is connected to the upper surface of the worktable 2, and the positioning system is located on the outer side of the guide roller assembly 4; a push printing system is connected to the rear of the upper surface of the worktable 2; system.

[0034] It also includes a first suction cup 5 ; three first suction cups 5 are installed in the middle of t...

Embodiment 2

[0037] On the basis of Example 1, as figure 1 , Figure 4 and Figure 5 As shown, the positioning system includes a first support base 101, a first rotating clamping column 102, a straight slide rail 103, a moving block 104, a positioner 105, a second rotating clamping column 106, a first supporting block 107, a first electric telescopic 108, the second supporting seat 109 and the third rotating clamping column 1010; the first supporting seat 101 is welded to the right part of the upper surface of the table 2, and the first supporting seat 101 is located behind the guide roller assembly 4; the first supporting seat 101 The upper part is rotatably connected with two first rotating clamping columns 102; the upper surface of the worktable 2 is fixed with a straight slide rail 103, and the straight slide rail 103 is located on the left side of the first support base 101; the straight slide rail 103 is slidably connected with a mobile Block 104; the upper part of the moving block...

Embodiment 3

[0043] On the basis of Example 2, as figure 1 , Figure 4 , Image 6 , Figure 7 and Figure 8 As shown, the push printing system includes a first support plate 201, a first electric slide rail 202, a first electric slider 203, a fixed beam 204, a second electric telescopic piece 205, a first support frame 206, a servo motor 207, a bidirectional The screw rod 208, the limit rod 209, the first fixed block 2010, the third electric telescopic piece 2011, the second support plate 2012, the first suction pipe 2013 and the silk screen assembly 2014; the upper surface of the table 2 is fixed with two symmetrical Each of the two first support plates 201 is bolted with a first electric slide rail 202; each of the two first electric slide rails 202 is slidably connected with a first electric slider 203; two A fixed beam 204 is fixed between the opposite sides of the first electric slider 203; the fixed beam 204 is fixed with two symmetrical second electric telescopic parts 205; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com