Device and method for double-sided precise targeting of HDI (High Density Interconnection) plate

A precise, double-sided technology, applied to PCB positioning, printed circuit components, printed circuits, etc. The effect of improving working strength and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

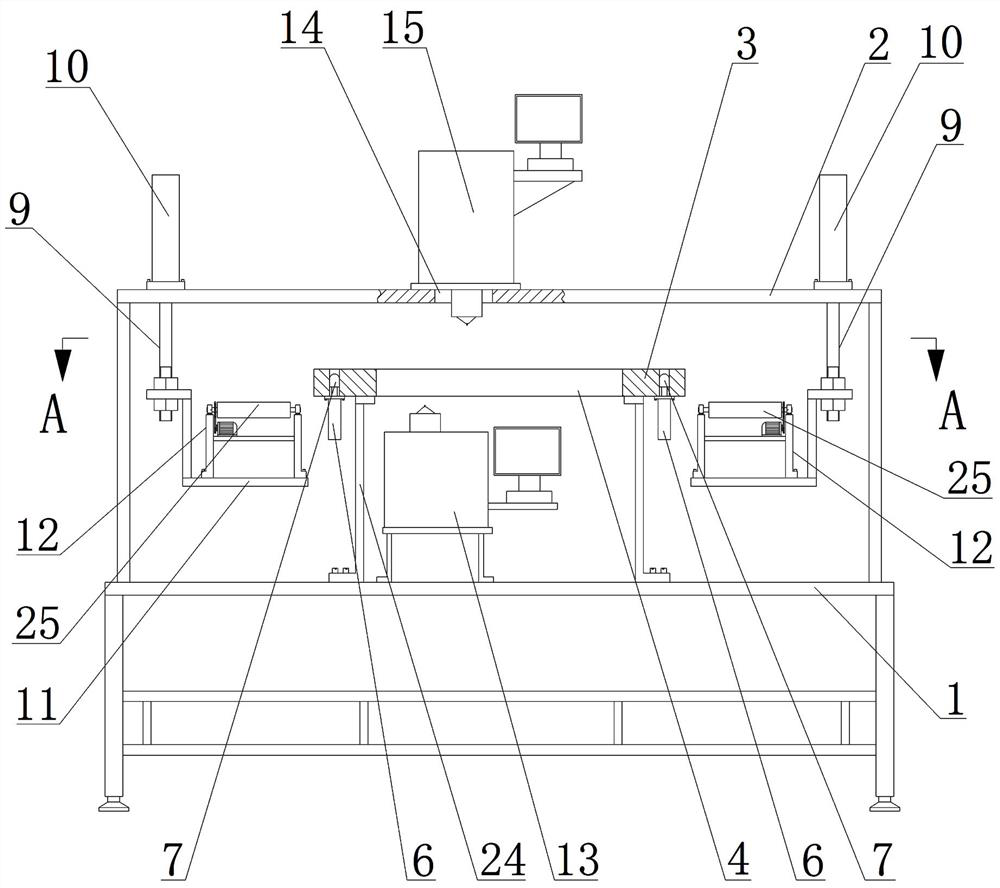

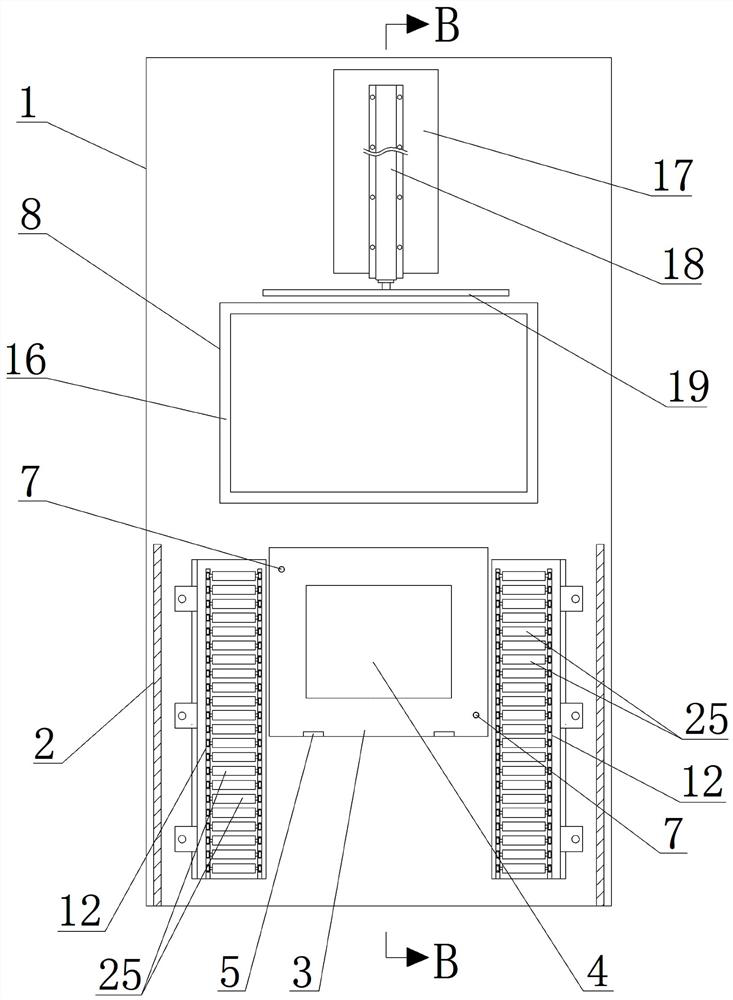

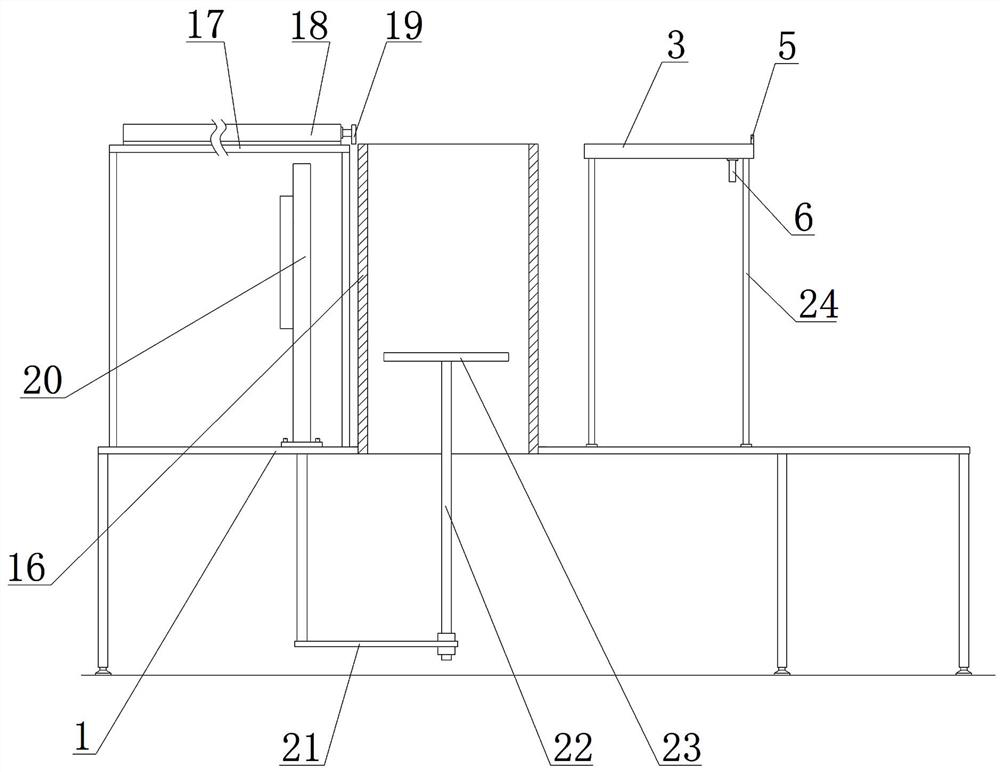

[0042]The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following:

[0043] like Figure 1~Figure 3 As shown, a device for double-sided precision shooting of HDI board, which includes a workbench 1, a gantry 2 fixed on the workbench 1, the bottom surface of the workbench 1 is fixed with a plurality of supports on the ground A positioning table 3 is arranged above the work table 1, a through slot 4 is opened in the middle of the positioning table 3, and a limit plate 5 is fixed on the top surface of the positioning table 3 and located on its front edge. The top surface of the table 3 is provided with two guide holes arranged diagonally, and a jacking cylinder 6 fixed on the positioning table 3 is arranged directly below the two guide holes. The working end of the piston rod of the jacking cylinder 6 A floating column 7 , which is slidably installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com