Aluminum material arc-bending mold

A technology of aluminum profiles and materials, applied in forming tools, manufacturing tools, feeding devices, etc., to achieve the effects of improving production efficiency, smooth discharging process, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

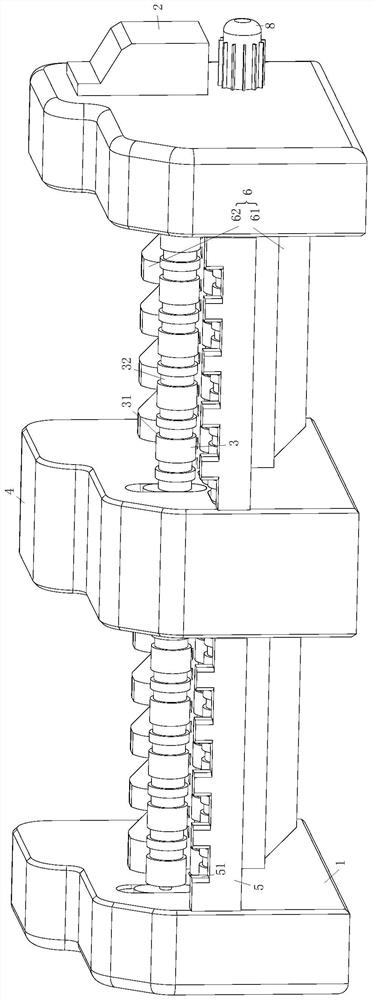

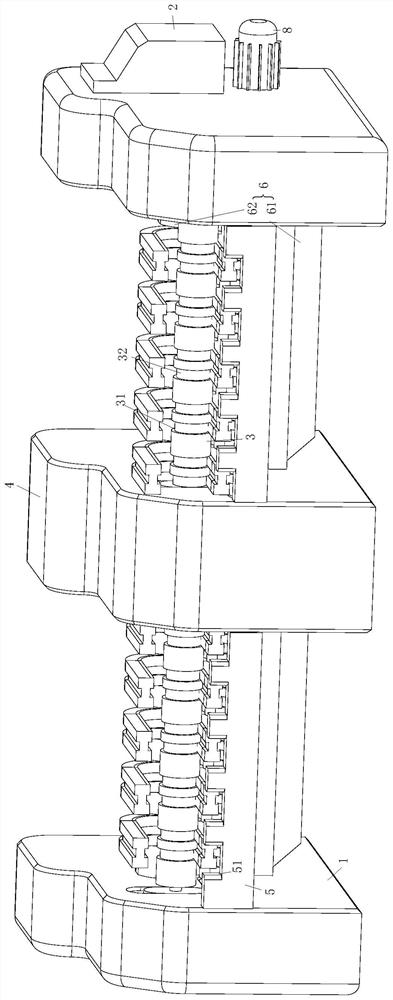

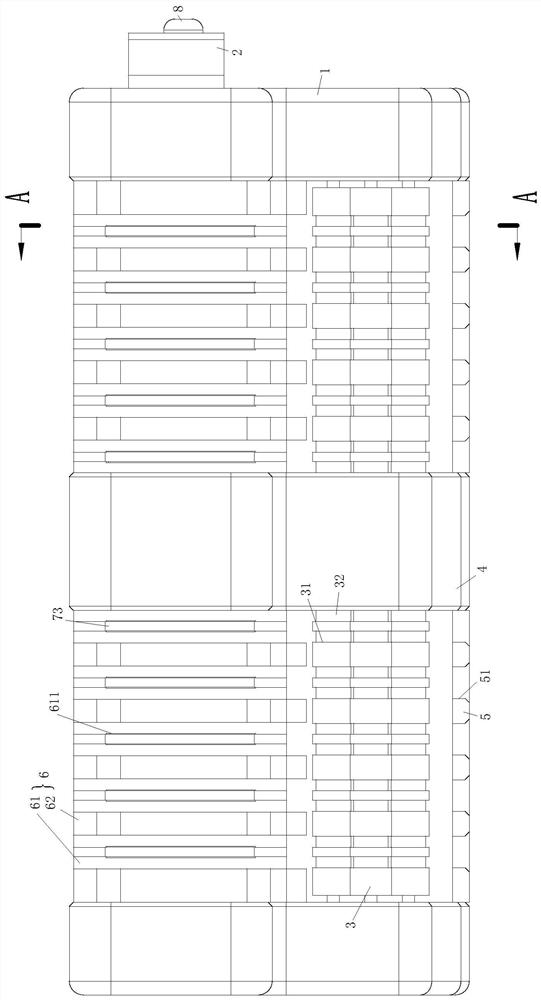

[0046] In the present invention, the shaping roller 3 is used to replace the existing bending mold, and the shaping roller 3 is fixedly installed in the middle of the machine bases 1 on both sides, and the middle seat 4 is used for support, so as to avoid the bending deformation of the shaping roller 3, and at the same time In addition to the support function, the seat 4 also has the function of enhancing the rotation force of the shaping roller 3, so that the present invention can simultaneously perform arc bending operations on multiple aluminum profile raw materials, which greatly improves the single-piece processing compared with the existing arc bending machine. The production efficiency is improved; the positioning groove 31 on the shaping roller 3 plays a role in positioning the aluminum profile along the axial direction of the shaping roller 3, so that the feeding of the aluminum profile is always kept in a vertical plane.

[0047] As an embodiment of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com