A kind of pitch control mechanism for steel bar thread processing machine

A thread processing and pitch control technology, applied in metal processing equipment, thread trimmers, manufacturing tools, etc., can solve the problems of cumbersome and laborious operation, increase displacement distance, thread processing distance error, etc., to simplify operation steps, improve production efficiency, The effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

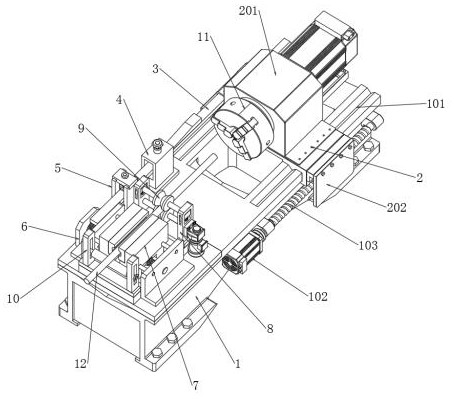

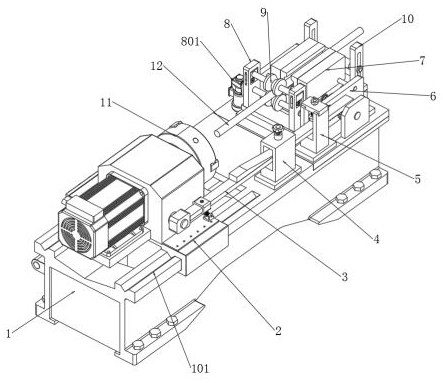

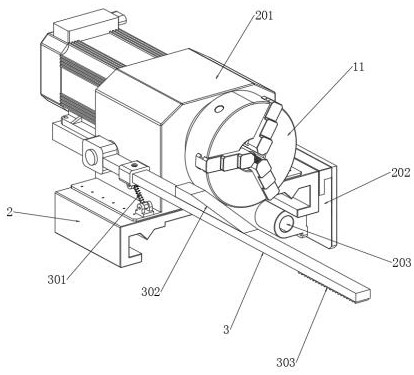

[0034] Example: please refer to Figure 1 to Figure 8 :

[0035]The present invention provides a pitch control mechanism for a steel bar thread processing machine, comprising: a workbench 1, guide rails 101 are provided on both sides of the top of the front half of the workbench 1, a first servo motor 102 is provided at the right end of the workbench 1, and the first servo The rotating shaft of the motor 102 is provided with a screw rod 103, and the screw rod 103 is rotatably connected to the worktable 1 through a bearing seat; a sliding frame 2 is provided on the front side of the top of the worktable 1, and a processing head 11 is provided above the sliding frame 2; sliding The top of the frame 2 is provided with a mounting seat 201, and the processing head 11 is fixedly installed on the mounting seat 201, and the left side of the mounting seat 201 is rotated to install the limiting strut 3, and the right end of the sliding frame 2 is provided with a connecting plate 202, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com