Industrial equipment health prediction method based on Internet of Things edge computing

A technology of industrial equipment and edge computing, applied in computing, computing models, computer components, etc., to achieve the effect of ensuring integrity and accuracy

Inactive Publication Date: 2022-06-10

合肥金人科技有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004]In the existing method, the collected industrial equipment data is only preprocessed, and it does not consider that when the collected equipment data is partially lost, resulting in a small sample size and there are samples In the meantime, there is no forecast standard to evaluate the forecast results, which eventually leads to inaccurate subsequent forecasts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

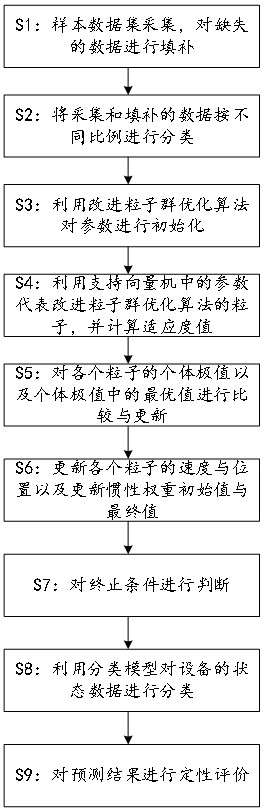

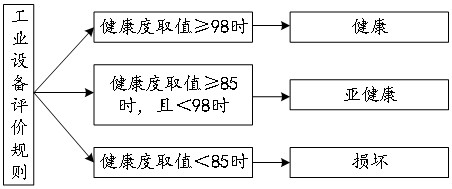

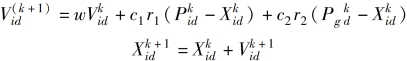

The invention discloses an industrial equipment health prediction method based on Internet of Things edge computing, and the method comprises the steps: collecting a sample data set, and carrying out the filling of missing data; classifying the collected and filled data according to different proportions; initializing parameters by using the improved particle swarm optimization model; representing the particles by using parameters in the support vector machine, and calculating a fitness value; comparing and updating the individual extreme value of each particle and the optimal value in the individual extreme values; updating the speed and the position of each particle and updating the initial value and the final value of the inertia weight; judging a termination condition; classifying the state data of the equipment by utilizing a classification model; performing qualitative evaluation on the prediction result; according to the method, the gray dynamic prediction model is used for filling, the data integrity is ensured, the health state of the industrial equipment is predicted by using the improved particle swarm algorithm, the prediction standard is set to evaluate the prediction result, and the accuracy of the prediction result is ensured.

Description

technical field [0001] The invention relates to the field of industrial equipment health, in particular to a method for predicting the health of industrial equipment based on edge computing of the Internet of Things. Background technique [0002] The "Industry 4.0" reform has accelerated the development of sensor technology, wireless communication technology, and computing systems. A large amount of monitoring data has poured into the field of industrial manufacturing, and it has also brought unprecedented challenges to the research of equipment health monitoring systems. With the vigorous development of modern industrial technology, the reliability and maintenance level of industrial equipment has become a necessary condition to ensure the normal operation of the system. In the actual production process, with the increase of equipment use time, the performance of the equipment is declining. If effective maintenance is not carried out, the equipment may fail or break down, w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F30/25G06F30/27G06K9/62G06N3/00

CPCG06F30/25G06F30/27G06N3/006G06F18/2411G06F18/214

Inventor 刘洋谢颖付晓晨

Owner 合肥金人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com