Die forging crack identifying, positioning and improving method based on binocular vision

A technology of crack identification and binocular vision, applied in neural learning methods, biological neural network models, image analysis, etc., can solve the problem of cracks and no further research and application, to improve the production efficiency of enterprises, save time, and improve efficiency. Accurately identify the effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

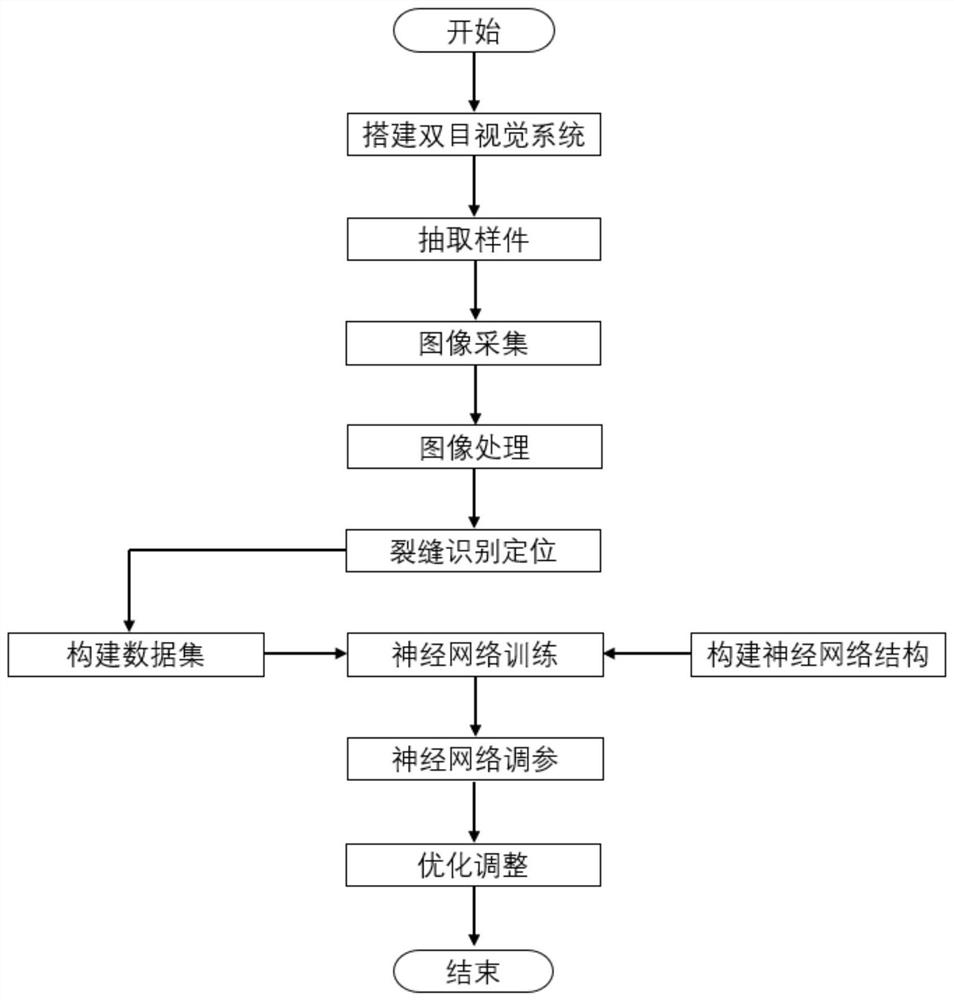

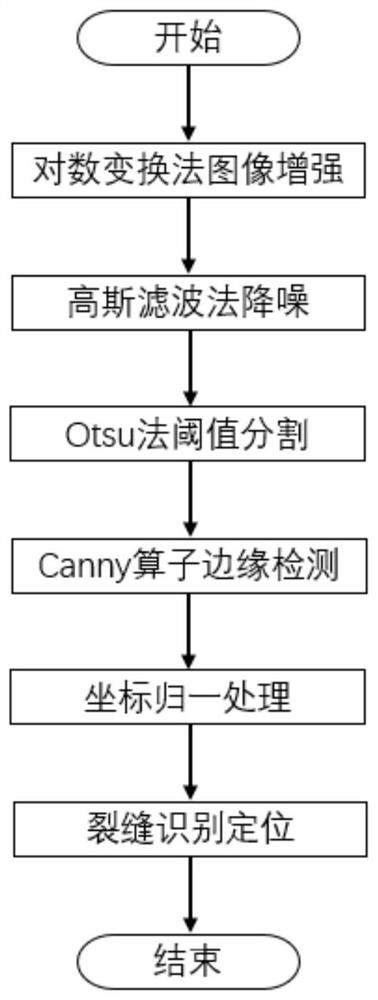

[0050] like figure 1 As shown, this embodiment provides a binocular vision-based method for identifying and locating cracks in die forgings and improving, including the following steps:

[0051] 1) The binocular vision system is used to obtain the image data of several historical die forgings with cracks, specifically:

[0052] 1.1) Build a binocular vision system, including left camera, left lens, right camera, right camera, fixed bracket, trigger, light source and computer.

[0053] 1.2) Select a camera in the binocular vision system as the main camera to collect images of several historical die forgings with cracks, and obtain image data of several historical die forgings with cracks.

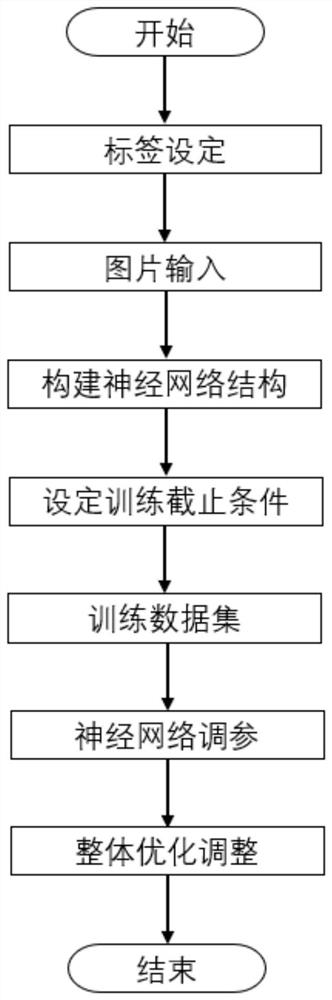

[0054] Specifically, it is found from several historical die forgings that the surface contains historical die forgings with cracks due to material properties, processes and molds. A historical die forging with cracks may include one or more cracks. The network can be effectively trained, ...

Embodiment 2

[0088] This embodiment provides a binocular vision-based crack identification, positioning and improvement system for die forgings, including:

[0089] The data set building module is used to construct a neural network data set for crack identification and localization based on the image data of several historical die forgings with cracks and their corresponding crack coordinates and the causes of cracks.

[0090] The identification module is used to obtain the image data of the die forging to be identified, process it, and input it into the constructed neural network data set to determine the crack coordinates and the crack type of the to-be-identified die forging.

Embodiment 3

[0092] This embodiment provides a processing device corresponding to the binocular vision-based crack identification, positioning and improvement method for die forgings provided in Embodiment 1, and the processing device may be a processing device for a client, such as a mobile phone, a notebook computer, a tablet computer, desktop computer, etc., to execute the method of Embodiment 1.

[0093] The processing device includes a processor, a memory, a communication interface and a bus, and the processor, the memory and the communication interface are connected through the bus to complete mutual communication. A computer program that can be run on the processing device is stored in the memory, and when the processing device runs the computer program, the binocular vision-based crack identification, positioning and improvement method for a die forging provided in Embodiment 1 is executed.

[0094] In some implementations, the memory may be a high-speed random access memory (RAM: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com