Discharging nozzle and biscuit casting forming and manufacturing method using discharging nozzle

A technology of pouring molding and discharge nozzle, applied in the direction of baking method, application, dough/premix, etc., can solve the problems of single taste and unable to meet the consumption expectations of young consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

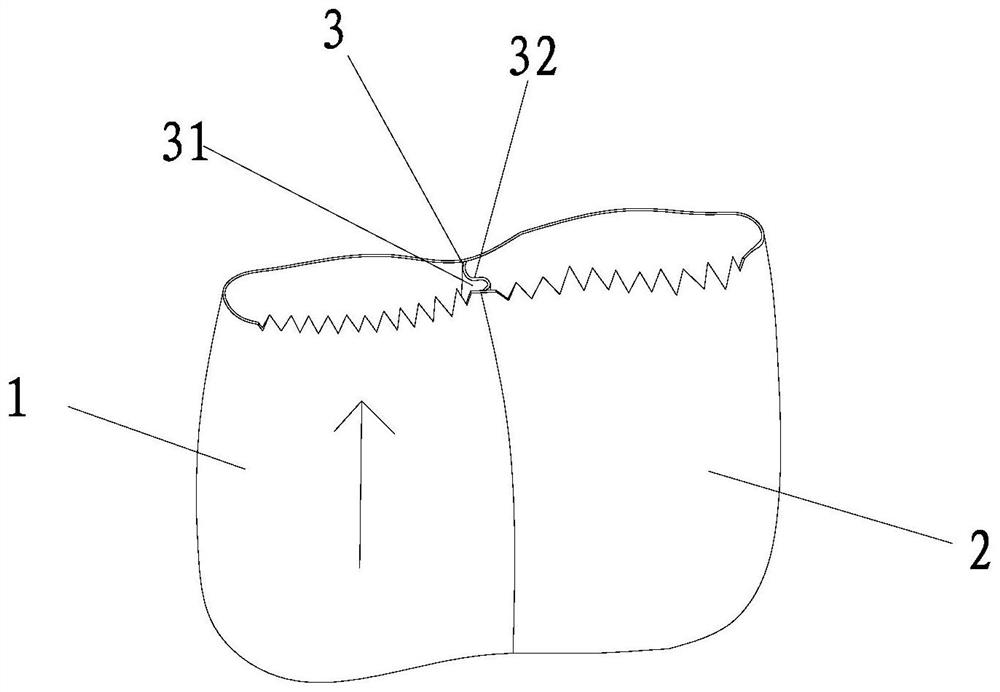

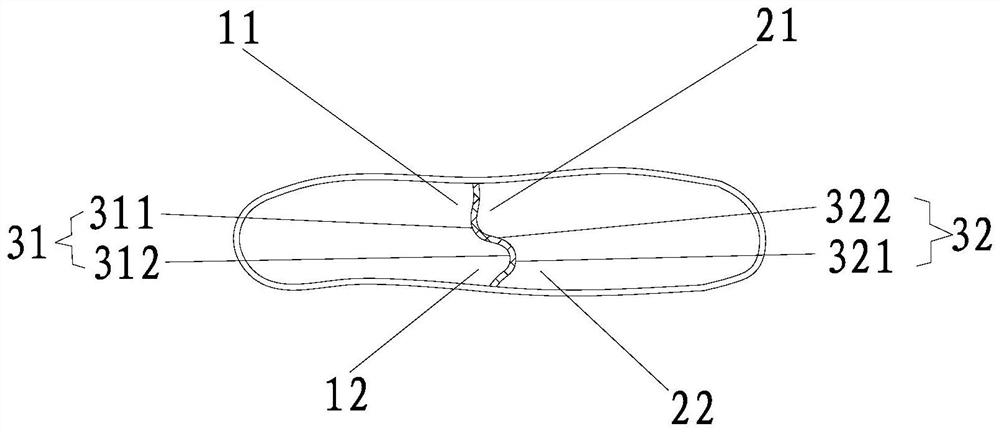

[0045] A discharge nozzle for food baking, such as figure 1 and figure 2 As shown, at least a first discharge nozzle 1 and a second discharge nozzle 2 are included. The first discharge nozzle 1 has a first discharge cavity, and the second discharge nozzle 2 has a second discharge cavity. A first partition plate is arranged between the material cavity and the second discharge cavity, and both the first discharge cavity and the second discharge cavity are independent cavities.

[0046] The part of the first partition plate at the discharge end is the first curved plate 3, the first curved plate 3 includes a first curved surface 31 and a second curved surface 32, the first curved surface corresponds to the first discharge cavity, the The second curved surface corresponds to the second discharge cavity, and the first curved surface 31 includes a first convex curved surface 311 and a first concave curved surface 312 that are connected to each other. The second curved surface 32 ...

Embodiment 2

[0054] A method of casting and molding a two-color biscuit of the present invention, using the discharge nozzle described in Embodiment 1, the method includes the following steps:

[0055] like Figure 5 As shown, when pouring, two different colors and / or flavors of slurry are divided into a first slurry and a second slurry, the first slurry is injected into the first discharge nozzle 1, and the second slurry is injected into In the second discharge nozzle 2, the first slurry is reshaped when it passes through the first curved surface, and the second slurry is reshaped when it passes through the second curved surface.

[0056] The first slurry and the second slurry form a bite force from the moment they leave the corresponding discharge nozzle, and finally, a two-color integrated biscuit wet blank is formed. The two-color integrated biscuit wet blank includes the first slurry passing through the first discharge nozzle 1. The first wet blank a that is cast and formed, and the ...

Embodiment 3

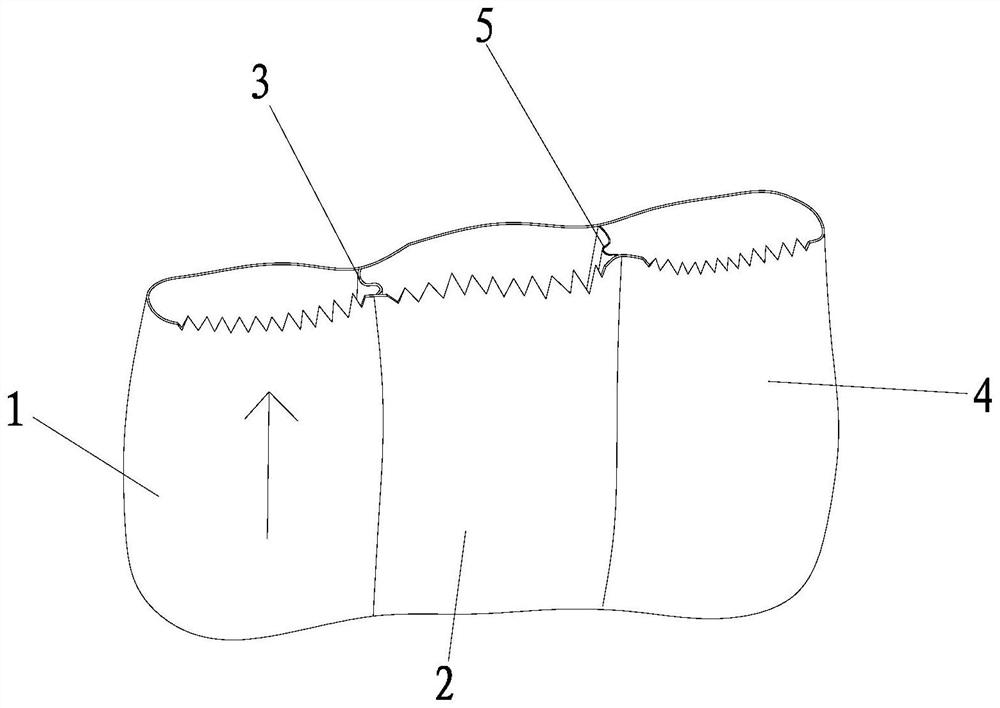

[0058] A method of casting and molding a two-color biscuit of the present invention, using the discharge nozzle described in Embodiment 1, the method includes the following steps:

[0059] like Image 6 As shown, when pouring, two different colors and / or flavors of slurry are divided into a first slurry and a second slurry, and the first slurry is injected into the first discharge nozzle 1 and the third discharge nozzle 4 , the second slurry is injected into the second discharge nozzle, and the first slurry and the second slurry are shaped when they pass through the first partition plate and the second partition plate respectively;

[0060] The first slurry and the second slurry form a bite force from the moment they leave the corresponding discharge nozzle, and finally, a two-color integrated biscuit wet blank is formed. The two-color integrated biscuit wet blank includes the first slurry passing through the first discharge nozzle 1. The first wet blank a formed by casting, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com